High voltage electrospinning method for preparing multi-fluorescence-encoded micro-beads

A technology of encoding microspheres and multiple fluorescence, which is applied in the field of fluorescence encoding, can solve the problems of difficulty in adding a large amount, tediousness, and difficulty in the addition process, and achieve good application and promotion value, simple operation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: polystyrene microspheres containing monochromatic CdSe / ZnS quantum dot material

[0043] Mix and dissolve 60g of styrene, 6g of acrylic acid, and 0.07g of azobisisobutyronitrile in tetrahydrofuran, heat at 70°C for 10 hours, then settle, wash and dry to obtain polystyrene, which is set aside;

[0044] Dissolve 2g of polystyrene in 18g of N,N-dimethylformamide to make its concentration 10%;

[0045] will have a maximum absorption at 612nm of 2×10 -4 g CdSe / ZnS (U.S. Ocean Nanotech product) quantum dot material ultrasonically dispersed in 5g chloroform;

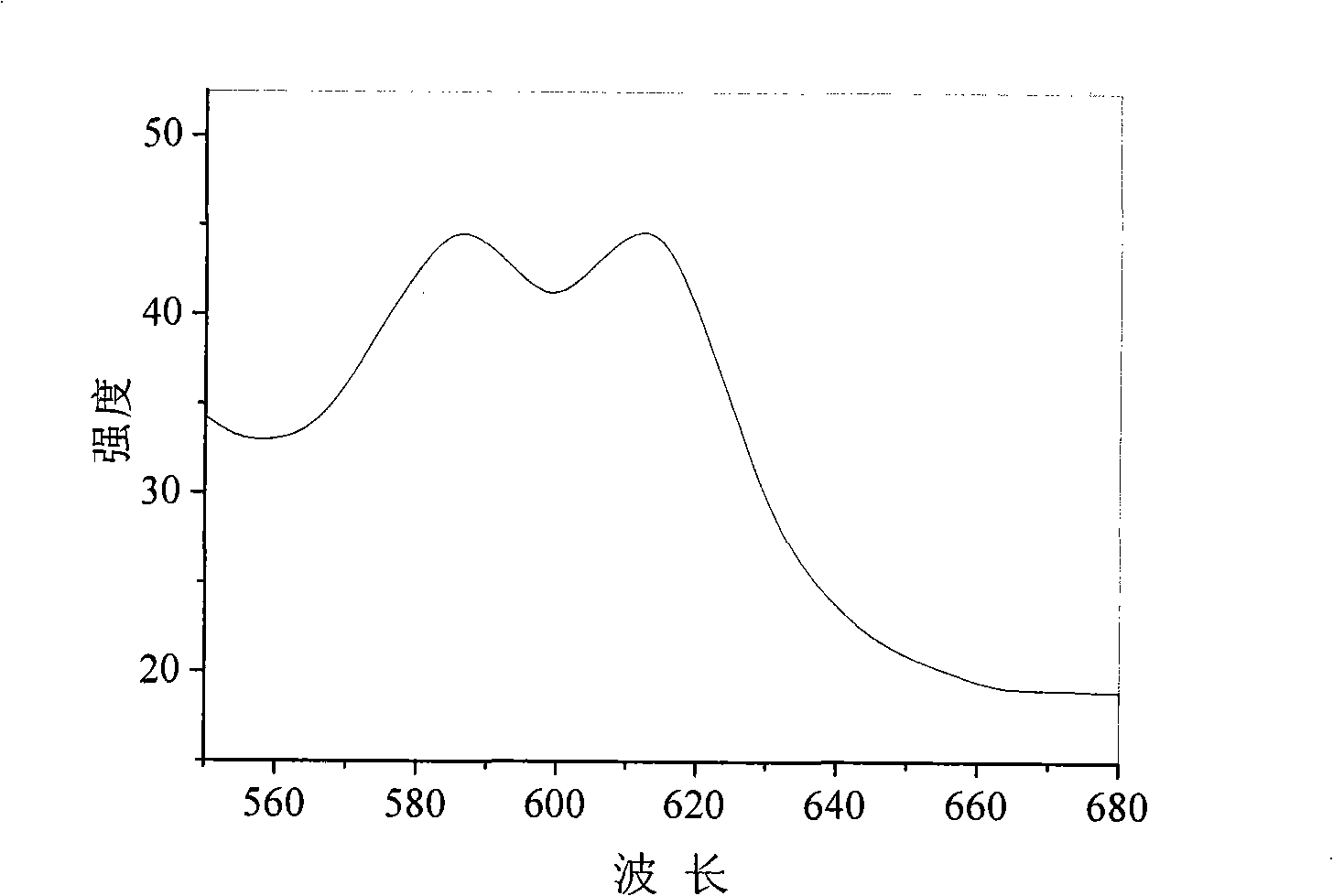

[0046] Mix 10g polystyrene N,N-dimethylformamide solution with 5g CdSe / ZnS chloroform solution, stir evenly, and ultrasonically disperse the quantum dot material in the polystyrene solution for 30 minutes, then add the solution to In the spinning tube of the electrospinning equipment, a nozzle with a diameter of 1 mm is installed, and the nozzle is connected to the positive electrode of the high-voltage p...

Embodiment 2

[0047] Embodiment 2: polystyrene microspheres containing two-color CdSe / ZnS quantum dot material

[0048] The preparation of polystyrene solution is as shown in embodiment 1;

[0049] will have a 4×10 maximum absorption at 612nm -4 g CdSe / ZnS quantum dot material ultrasonically dispersed in 5g chloroform;

[0050] will have a maximum absorption of 3.8×10 at 586nm -4 g CdSe / ZnS quantum dot material ultrasonically dispersed in 5g chloroform;

[0051] Mix 10g polystyrene solution with 2.5g CdSe / ZnS (612nm) and 2.5g CdSe / ZnS (586nm) chloroform solution of quantum dot material, stir for 5h, and ultrasonically disperse quantum dot material in polystyrene solution for 30 minutes , and then put the solution into the spinning tube, add a nozzle with a diameter of 1 mm, and connect the nozzle to the positive electrode of the high-voltage power supply as the anode, use aluminum foil as the negative electrode, adjust the distance between the positive and negative electrodes to be 10cm,...

Embodiment 3

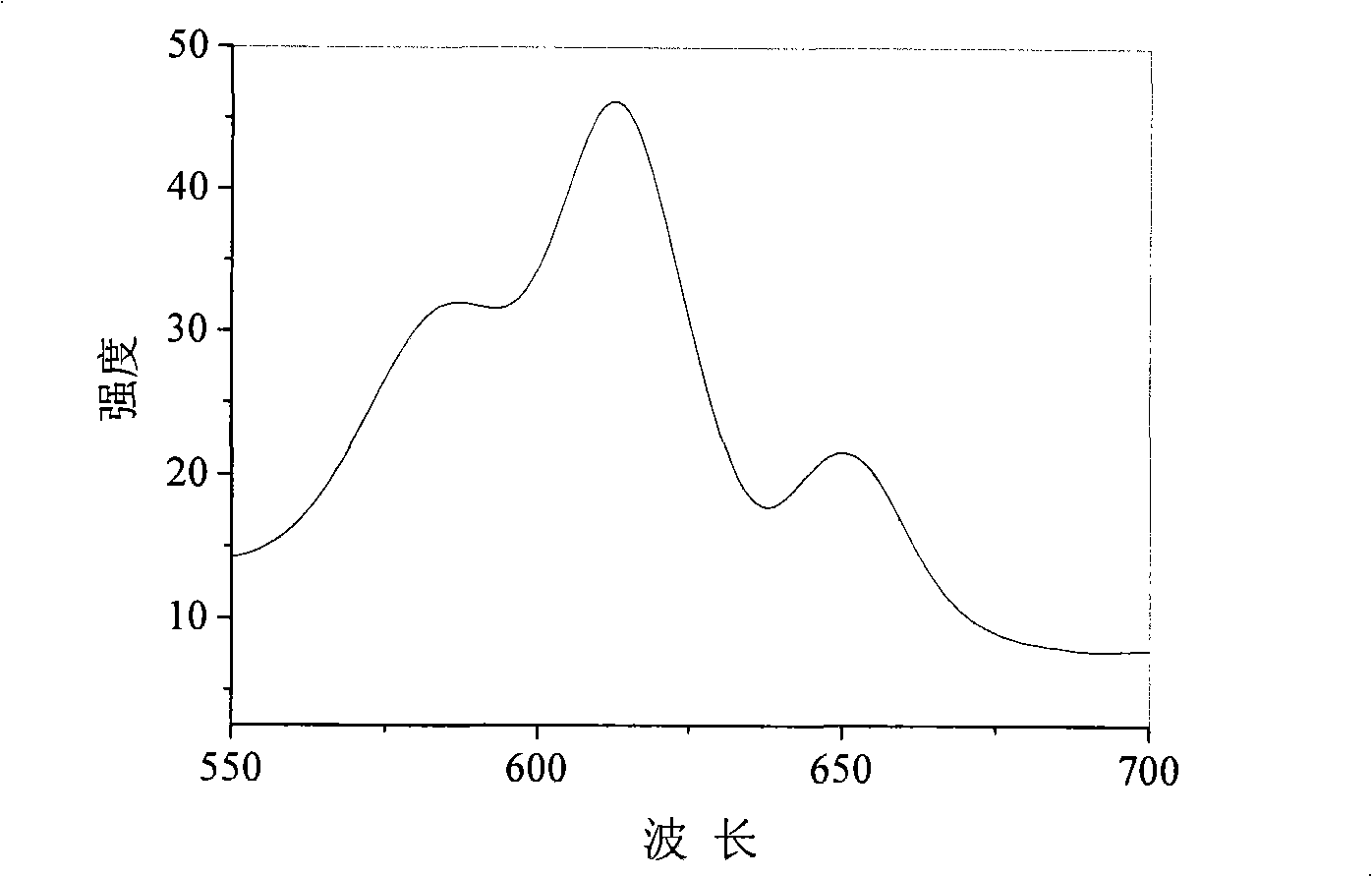

[0054] Example 3: Polystyrene microspheres containing three-color CdSe / ZnS quantum dots

[0055] The preparation method of polystyrene is implemented as embodiment 2 method;

[0056] will have a 4×10 maximum absorption at 612nm -4 g CdSe / ZnS quantum dot material ultrasonically dispersed in 5g chloroform;

[0057] will have a maximum absorption of 3.8×10 at 586nm -4 g CdSe / ZnS quantum dot material ultrasonically dispersed in 5g chloroform;

[0058] will have a maximum absorption of 3.3×10 at 530nm -4 g CdSe / ZnS quantum dot material ultrasonically dispersed in 5g chloroform;

[0059] Dissolve 2.0g of polystyrene in 15.5g of N,N-dimethylformamide, stir and set aside;

[0060] Get the polystyrene solution of 10g preparation, then add the chloroform solution of 2.5g CdSe / ZnS (618nm), 2.5gCdSe / ZnS (586nm), 2.5g CdSe / ZnS (530nm) quantum dot material, then adopt the implementation of embodiment 2 The corresponding polystyrene multicolor microspheres are prepared in the process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com