Method for preparing sulphur based compound fertilizer by decomposing rock phosphate with hydrogen nitrate and system thereof

A technology of compound fertilizer and phosphate rock powder, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., to achieve the effect of reducing energy consumption and corrosion, reducing intermediate steps, and direct and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

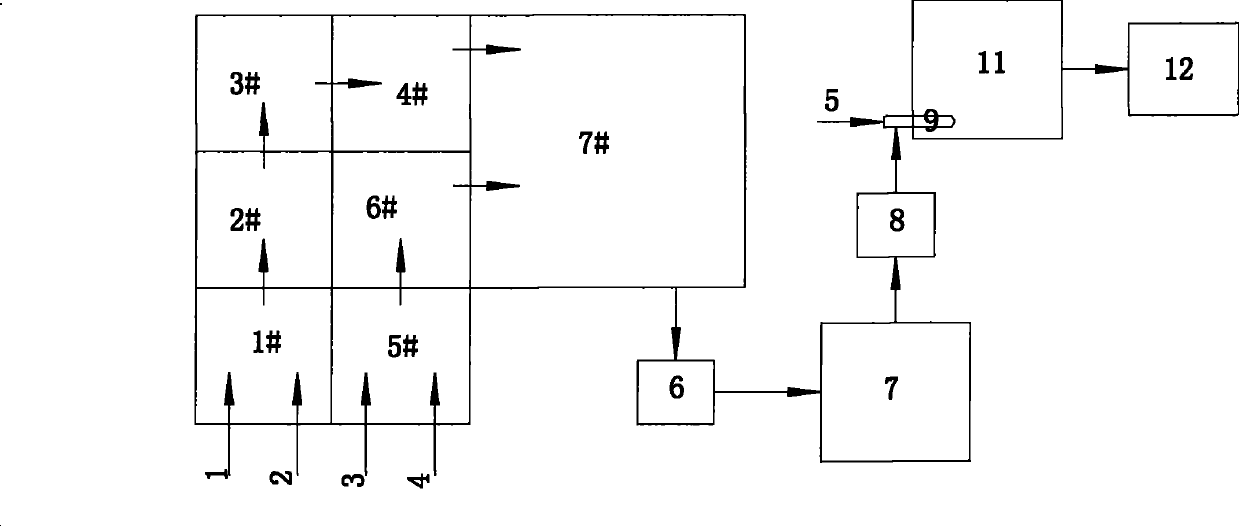

[0045] The nitro-sulfur-based liquid fertilizer is produced by using the concrete conversion tank, the mixed acid pump, the filter, the ammonia neutralization tank and the like in the present invention. See the process drawing for details figure 1 . Such as figure 1 Shown is a schematic process flow diagram of one of the embodiments of the present invention. Such as Figure 4 Shown is a schematic structural view of the concrete reaction tank used in the process flow of one of the embodiments of the present invention. The reaction tank is an integral structure, and there are interlayer partitions or gaps 3 between the tanks to buffer thermal expansion; the partitions 3 can be foamed plastics, polypropylene plates or rubber plates, and the gap width is 0.5-5mm; the reaction tank is a three-layer structure, the outer Layer 1 is ordinary concrete, middle layer 2 can be FRP, acid-resistant concrete, rubber plate, inner layer 4 can be acid-resistant tiles, silicon-free acid-resi...

Embodiment 2

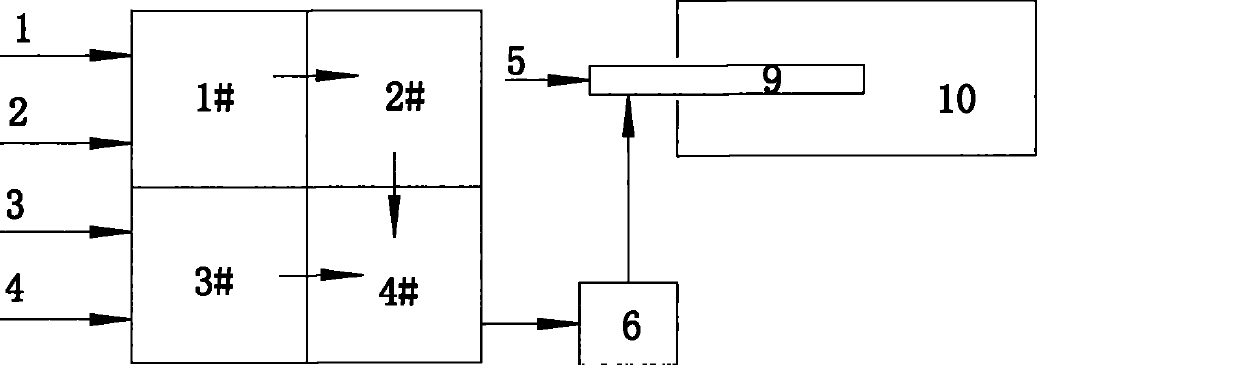

[0052] The nitro-sulfur-based granular fertilizer is produced by utilizing the concrete conversion tank, the mixed acid pump, the tubular reactor of the granulator and the like in the present invention. See the process drawing for details figure 2 . Such as figure 2 Shown is a schematic process flow diagram of the second embodiment of the present invention.

[0053] The 60% dilute nitric acid 3 produced by the nitric acid plant is measured by the flowmeter, and the 7.8m 3 Add 3# nitric acid to decompose the reaction tank of phosphate rock at the speed of / h, such as Figure 5 Shown is a schematic structural view of the concrete reaction tank used in the process flow of the second embodiment of the present invention. The reaction tank is an integral structure, and there are interlayer partitions or gaps 3 between the tanks to buffer thermal expansion; the partitions 3 can be foamed plastics, polypropylene plates or rubber plates, and the gap width is 0.5-5mm; the reaction...

Embodiment 3

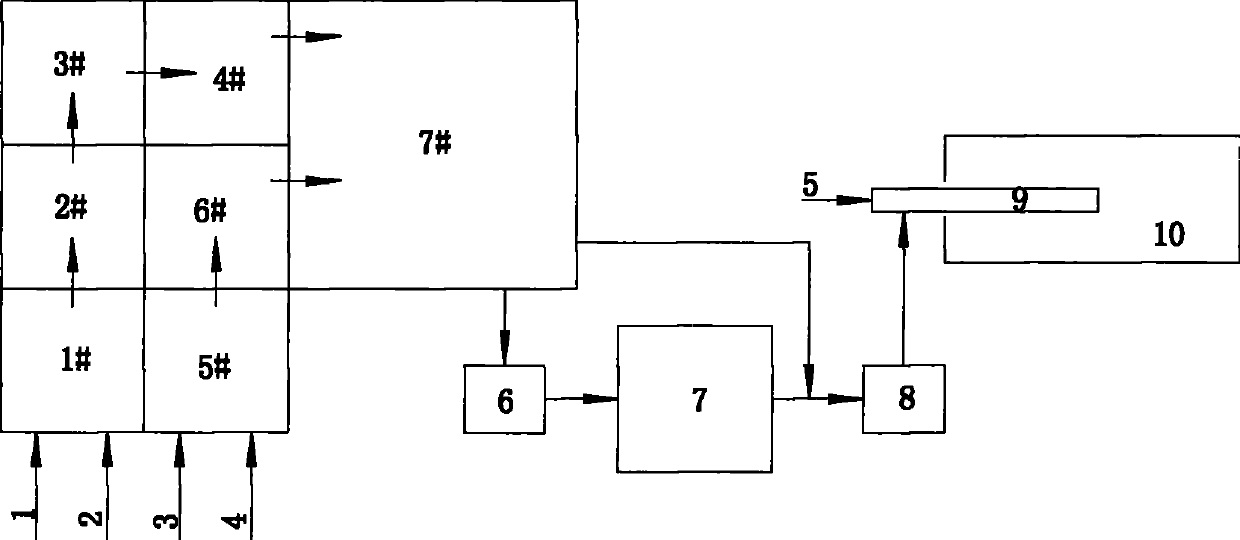

[0058] The nitro-sulfur-based granular fertilizer is produced by utilizing the concrete conversion tank, the mixed acid pump, the tubular reactor of the granulator and the like in the present invention. See the process drawing for details image 3 . Such as image 3 Shown is a schematic process flow diagram of the third embodiment of the present invention.

[0059] After the 60% dilute nitric acid 3 produced by the nitric acid plant is measured by the flow meter, it is measured at 5.1m 3 Add 5# nitric acid to the reaction tank for decomposing phosphate rock at a speed of / h, containing P 2 o 5 30% phosphate rock powder 4 is measured with a belt weighing scale and added at the same time at 8.4t / h. The reaction temperature is 80-100°C, and the reaction product overflows through the bottom opening of the partition wall between the reaction tanks to the 6# reaction tank where the phosphate rock is decomposed with nitric acid to continue the reaction. Finally, it overflows to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com