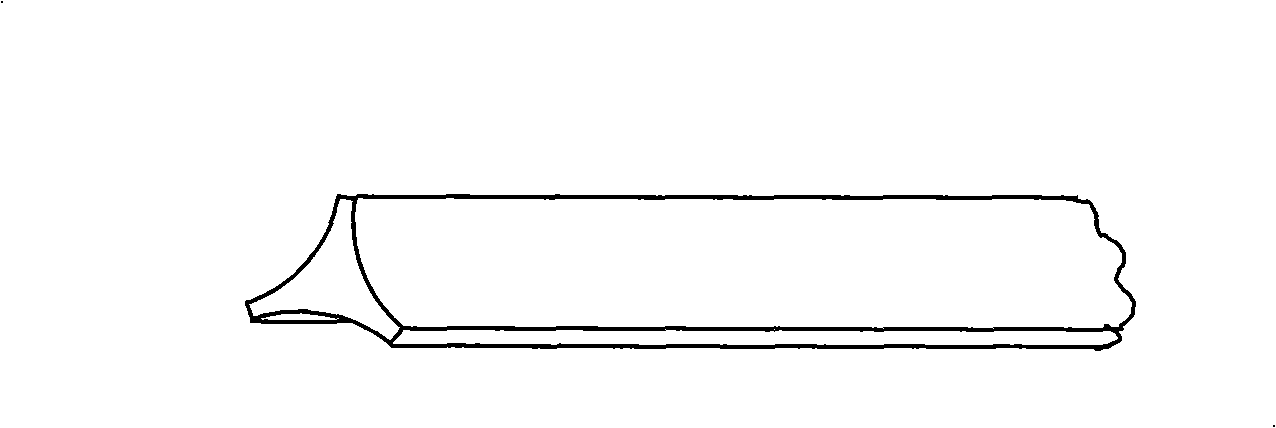

Concave cylinder regular triangular prism shaped aluminum oxide nanowire and in-situ preparation thereof

A technology of aluminum oxide nanometers and regular triangular prisms, which is applied in chemical instruments and methods, anodic oxidation, crystal growth, etc., can solve the problem of increasing the chemical corrosion time of porous aluminum oxide films, corrosion and damage of aluminum oxide nanotube structures, and is not published in literature 1, 2 and other problems, to achieve the effects of low production cost, high yield and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

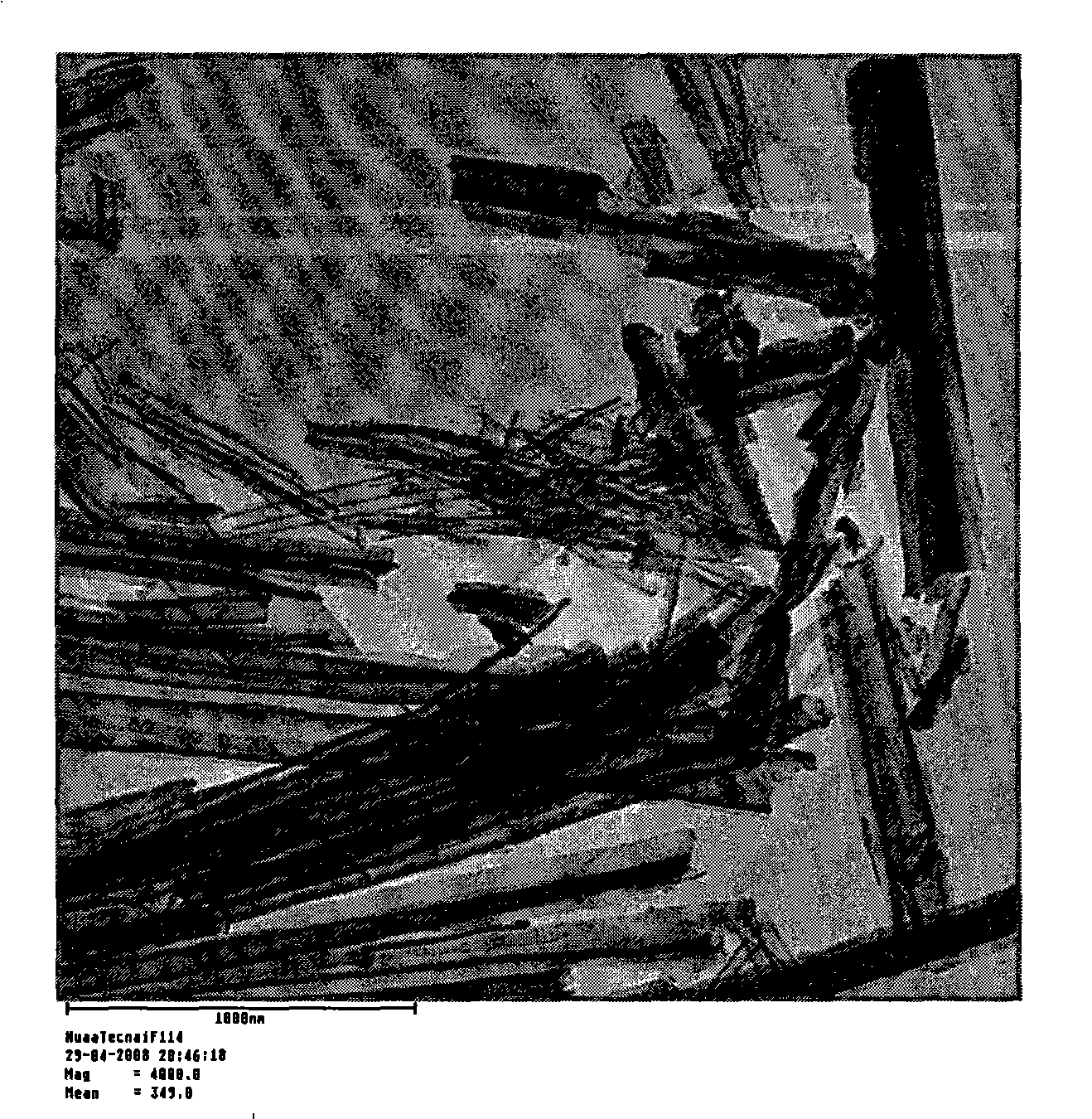

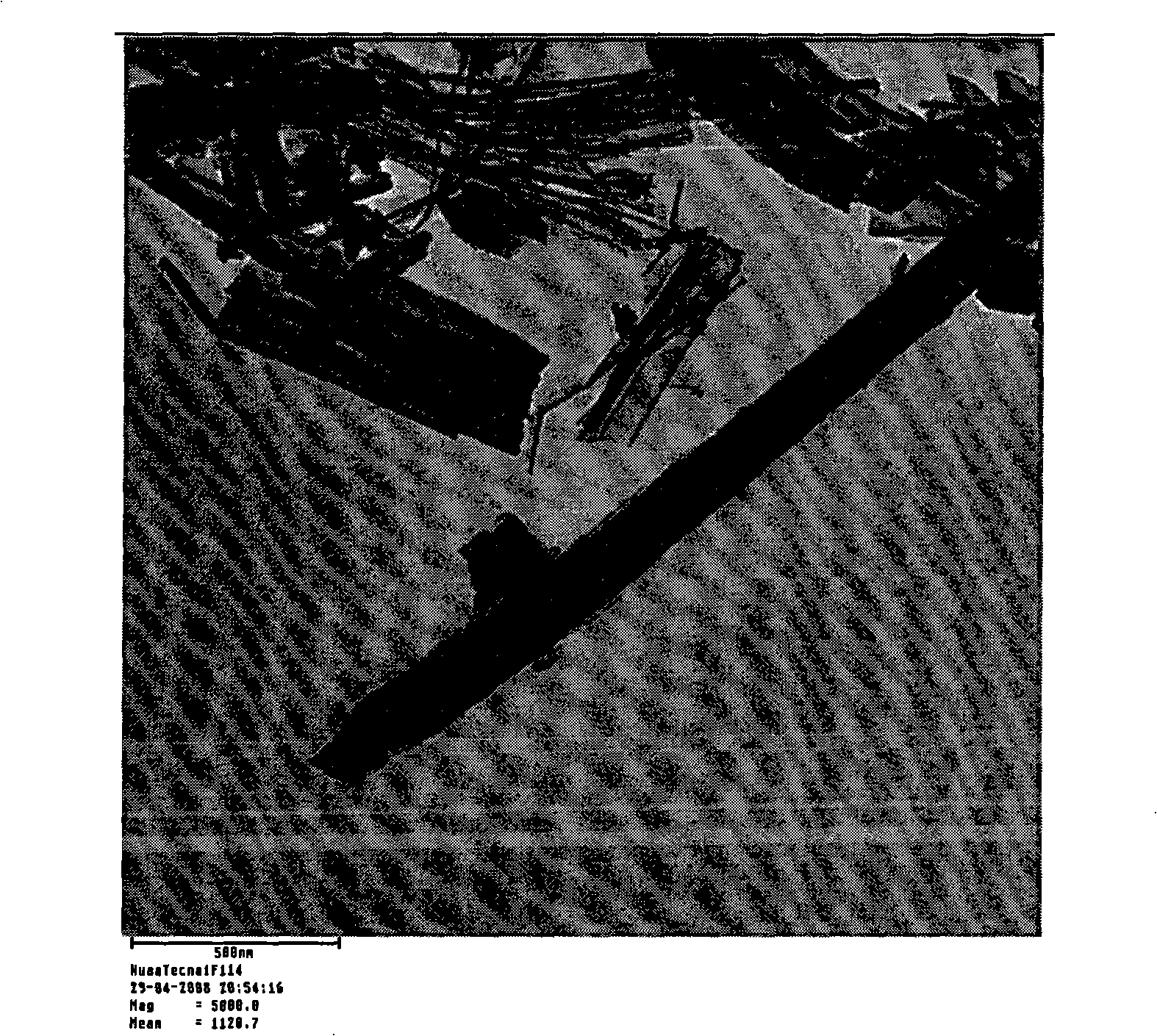

Image

Examples

Embodiment Construction

[0037] The preparation process of the regular triangular prismatic aluminum oxide nanowires with concave cylindrical surface of the present invention will be described in detail below. The specific method is as follows:

[0038] 1. Preparation of electrolyte solution: including the electrolyte solution required for electrochemical polishing and the electrolyte solution required for anodic oxidation. Among them: the polishing solution for electrochemical polishing is prepared from analytically pure perchloric acid and absolute ethanol, and the volume ratio of the two is 1:5 to 1:2; the electrolyte required for anodic oxidation is made of deionized The oxalic acid solution prepared by water and analytically pure oxalic acid, the concentration is 0.2mol / L~0.5mol / L.

[0039] 2. Preparation of the aluminum substrate: Use an aluminum sheet with a purity of 99.999% and ultrasonically clean it with analytically pure acetone and ethanol solutions for 10 minutes; put the aluminum sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com