Method for separating methanol and dimethyl carbonate azeotropic mixture

A technology of dimethyl carbonate and azeotropic mixture, applied in the field of separation of dimethyl carbonate, can solve the problems of product quality reduction, environmental pollution, high energy consumption, etc., and achieve the effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 NaY molecular sieve membrane

[0021] 38.01 grams of sodium hydroxide and 8.54 grams of NaAlO 2 Be dissolved in 236.9 grams of deionized water to obtain solution A; 188.55 grams of water glass (SiO 2 Content 27.3%) was mixed with 245.7 grams of deionized water to obtain solution B. Add solution A dropwise to solution B under vigorous stirring to obtain the precursor sol of NaY molecular sieve. After continuing vigorous stirring for 2 hours, it was aged at room temperature for 12 hours. The pre-coated α-Al with NaY molecular sieve seeds 2 o 3 Membrane tube (outer diameter 13mm, wall thickness 2mm, length 35cm, average pore diameter 1.0μm, porosity 38%) both ends are sealed with PTFE tape and vertically fixed in the synthesis reactor, the molecular sieve precursor sol is transferred in the reactor, Crystallization treatment was carried out for 5 hours in a blast oven preheated to 100°C. After the reaction, the molecular sieve membrane...

Embodiment 2

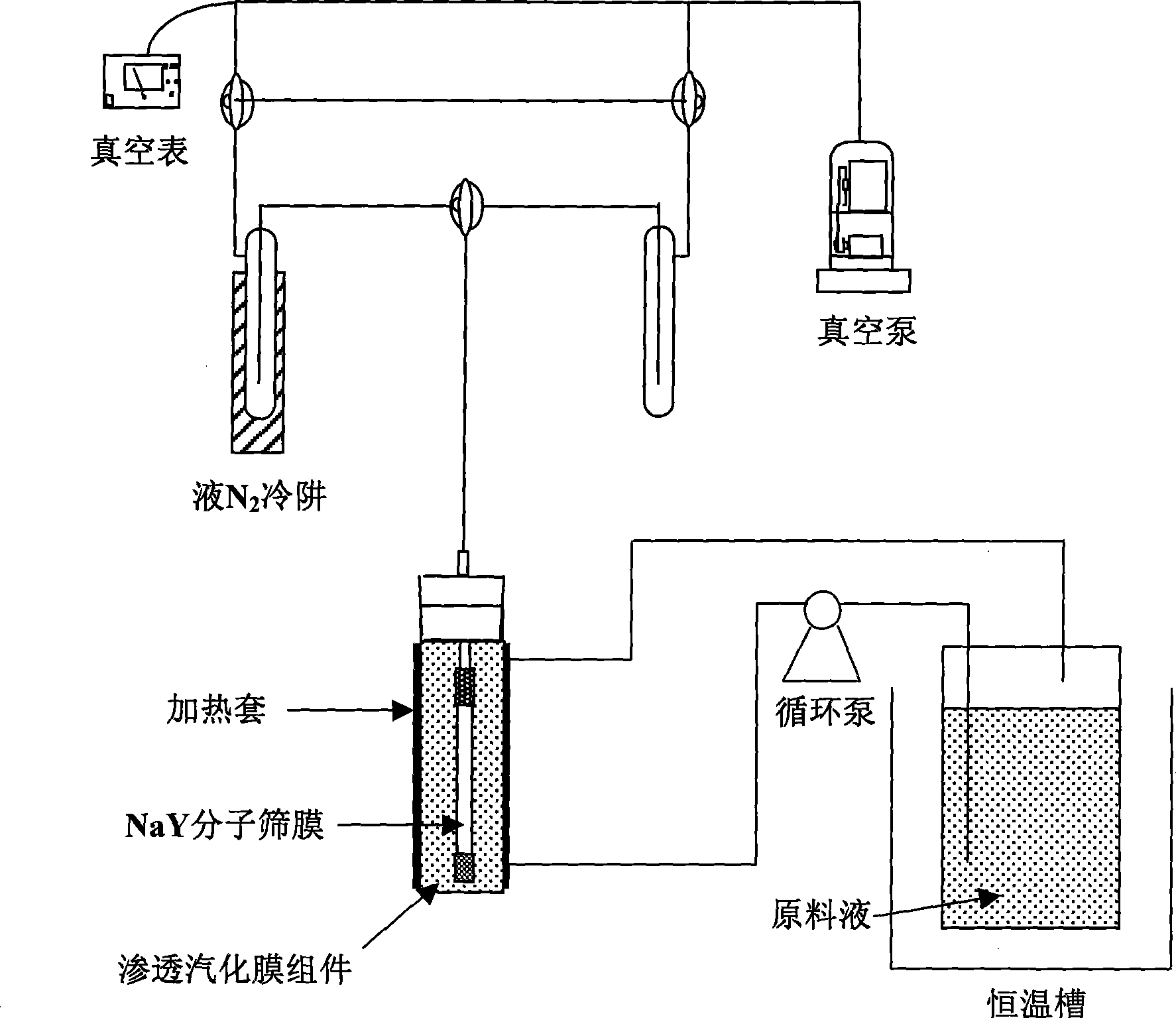

[0022] Example 2 Pervaporation separation of methanol and dimethyl carbonate

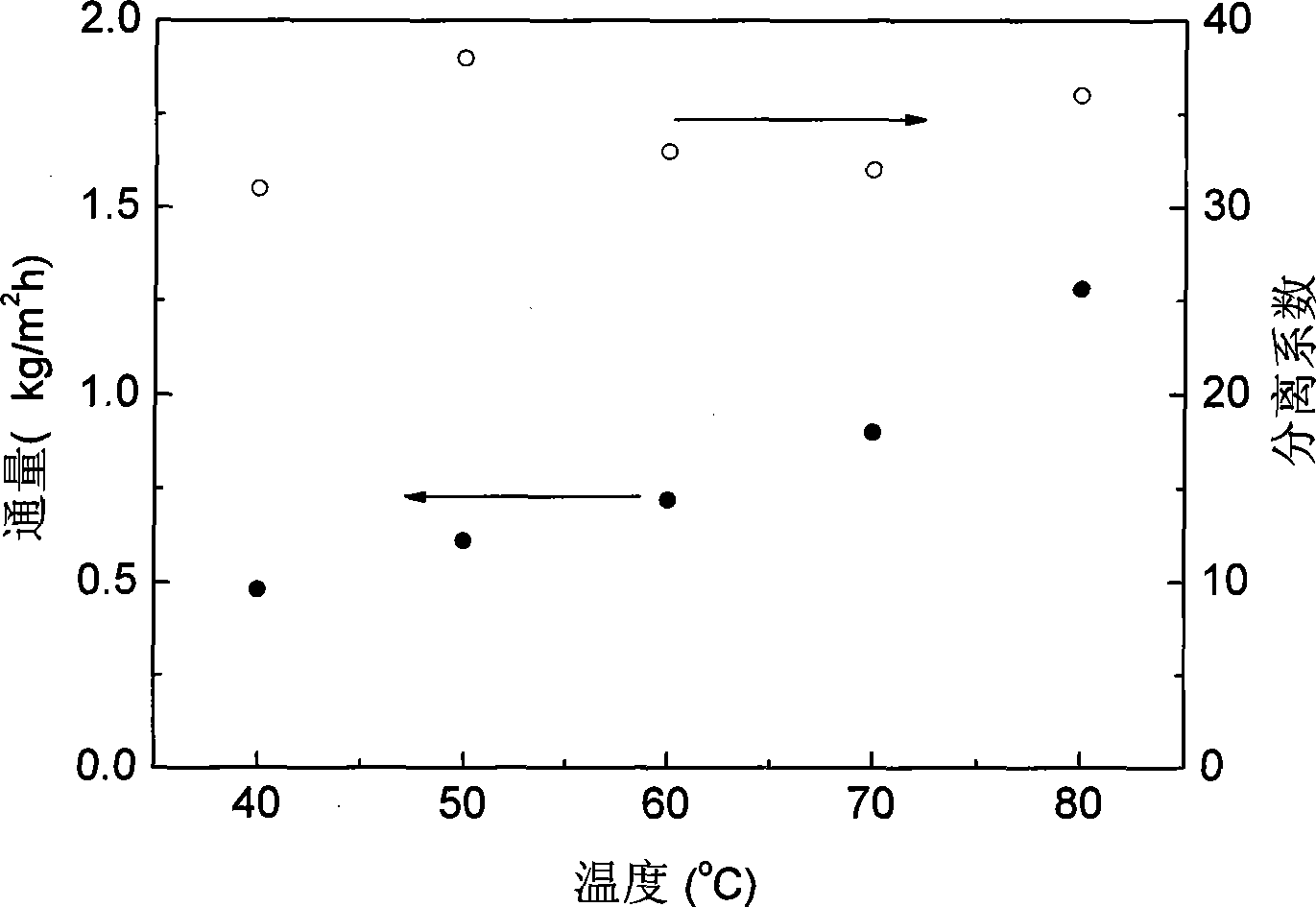

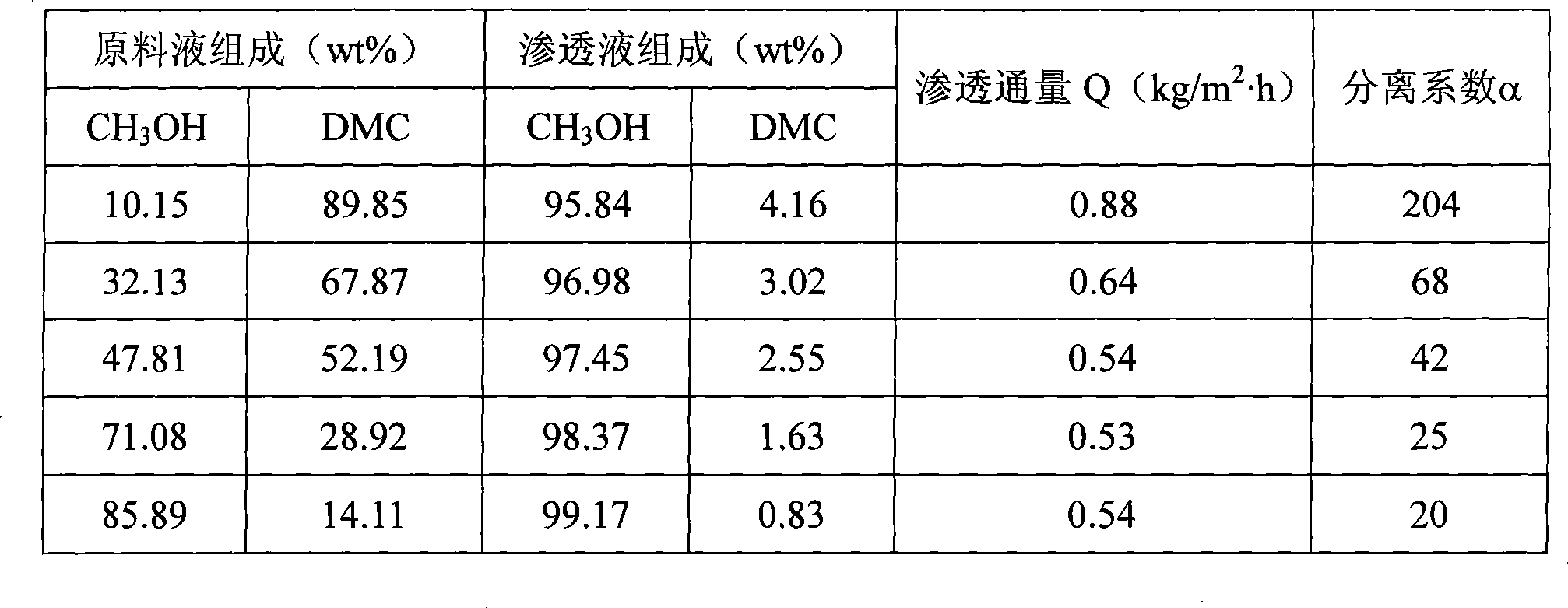

[0023] Figure 1 It is a schematic diagram of a pervaporation separation device for the separation of methanol and dimethyl carbonate in the present invention. The NaY molecular sieve membrane tube is placed in a stainless steel assembly, one end is connected to a small section of PTFE rod, the other end is connected to a vacuum system, and the two ends are sealed with a silicone rubber tube and a thermoplastic tube in sequence, and the outside of the assembly is wrapped with a heating tape. The raw material liquid heated to 50°C in the constant temperature tank is circulated and supplied in the module through the liquid pump, and liquid N is used for permeating steam. 2 Condensation is recovered, and two cold traps are switched to ensure continuous measurement. The permeate collected by condensation is weighed with an electronic balance, and the concentrations of the raw material liquid and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com