Preparation method of composite colloidal sol for improving ink jet fastness

A composite sol and solvent technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as paint dyeing or printing fixation effect not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the treatment of composite sol of cotton-nylon blended woven fabric with monochromatic color block inkjet printing with paint ink

[0031] 58 parts of propanol, 21 parts of tetraethyl orthosilicate and 10 parts of water were successively added into the Erlenmeyer flask. Stir on a magnetic stirrer (400rpm) for 20min, under this condition, add 2 parts of hydrochloric acid with a concentration of 0.01mol / L to the above solution at a rate of 40drop / min, stir for 2h, and then add tetraethyl titanate 9 share. Adjust the rotation speed of the magnetic stirrer (700rpm), stir continuously at room temperature for 24h, and let it stand and age for 2 days. With the above SiO 2 / TiO 2 The composite sol is used to pad the monochrome color block of the inkjet printing of the cotton-nylon blended fabric with two dipping and two padding. Bake for 8 minutes.

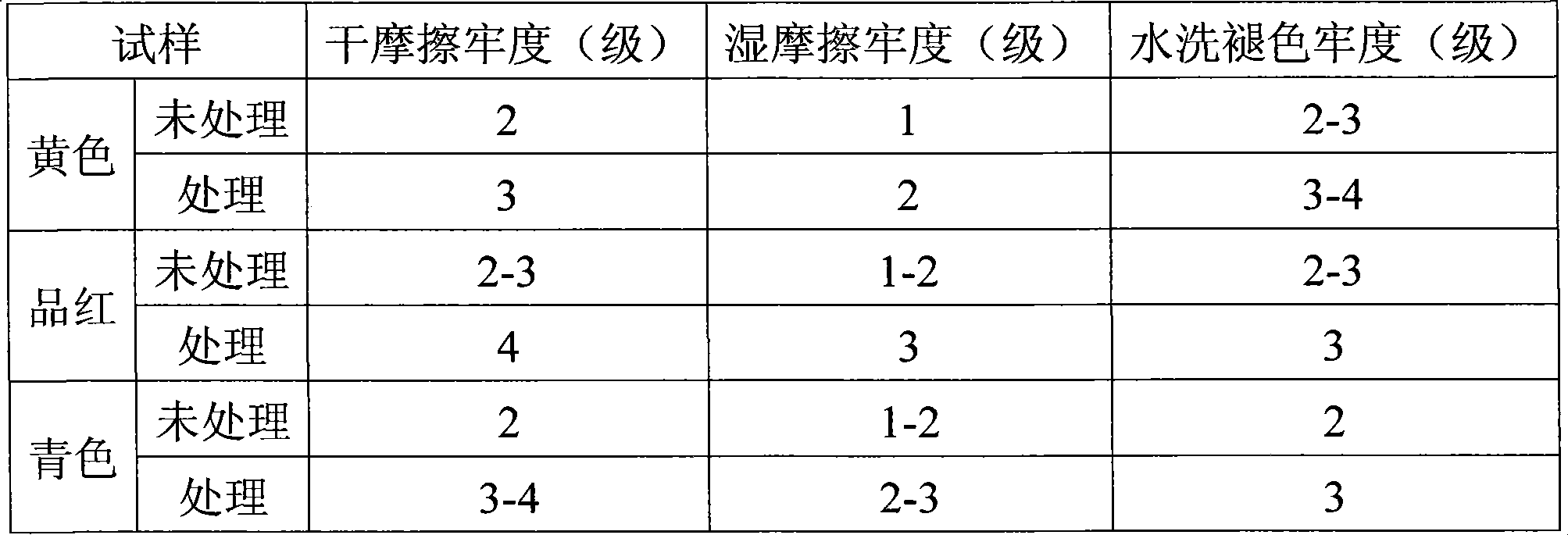

[0032] SiO 2 / TiO 2 The printing fastness of composite sol-treated and untreated cotton-nylon blended woven ...

Embodiment 2

[0036] Embodiment 2: the processing of the composite sol of pure cotton knitted fabric with inkjet printing of paint ink

[0037] 46 parts of ethylene glycol, 22 parts of methyl orthosilicate and 22 parts of water were successively added into the Erlenmeyer flask. Stir on a magnetic stirrer (500rpm) for 20min. Under this condition, add 4 parts of acetic acid with a concentration of 0.01mol / L to the above solution dropwise at a speed of 70drop / min. After stirring for 2h, add tetra-n-butyl titanate 6 servings. Adjust the rotating speed of the magnetic stirrer (1000rpm), stir continuously at room temperature for 24h, and let it stand for aging for 2 days. SiO prepared above 2 / TiO 2 The composite sol is used to impregnate the inkjet printed knitted fabric with paint ink: the liquor ratio is 1:30, the temperature is 50°C, and the treatment time is 10 minutes. The fabric was prebaked at 60°C for 30 minutes and then baked at 170°C for 5 minutes.

[0038] SiO 2 / TiO 2 After th...

Embodiment 3

[0039] Embodiment 3: Treatment of composite sol for inkjet printing polyester light box cloth with coating ink

[0040]41 parts of ethanol, 26 parts of orthobutyl silicate and 17 parts of water were successively added into the Erlenmeyer flask. Stir on a magnetic stirrer (800rpm) for 10min, under this condition, add 5 parts of nitric acid with a concentration of 0.01mol / L to the above solution dropwise at a speed of 30drop / min, stir for 2h, and then add tetrapropyl ortho titanate 11 servings. Adjust the rotation speed of the magnetic stirrer (300rpm), stir continuously at room temperature for 24h, and let it stand and age for 2 days. SiO prepared above 2 / TiO 2 The composite sol is used to impregnate the polyester light box cloth printed with paint ink and inkjet printing: the liquor ratio is 1:50, the temperature is 60°C, and the treatment time is 8 minutes. The light box cloth is pre-baked at 60°C for 25 minutes and then baked at 110°C for 15 minutes.

[0041] Polyester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com