C22 triacid triester elasticizer and method of preparing the same

A technology of ester plasticizer and triacid, which is applied in the field of C22 triacid triester plasticizer and the use of tung oil to prepare the plasticizer, can solve the problems of non-toxicity, biodegradability and high plasticizing ability , to achieve the effect of high flash point, good durability and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

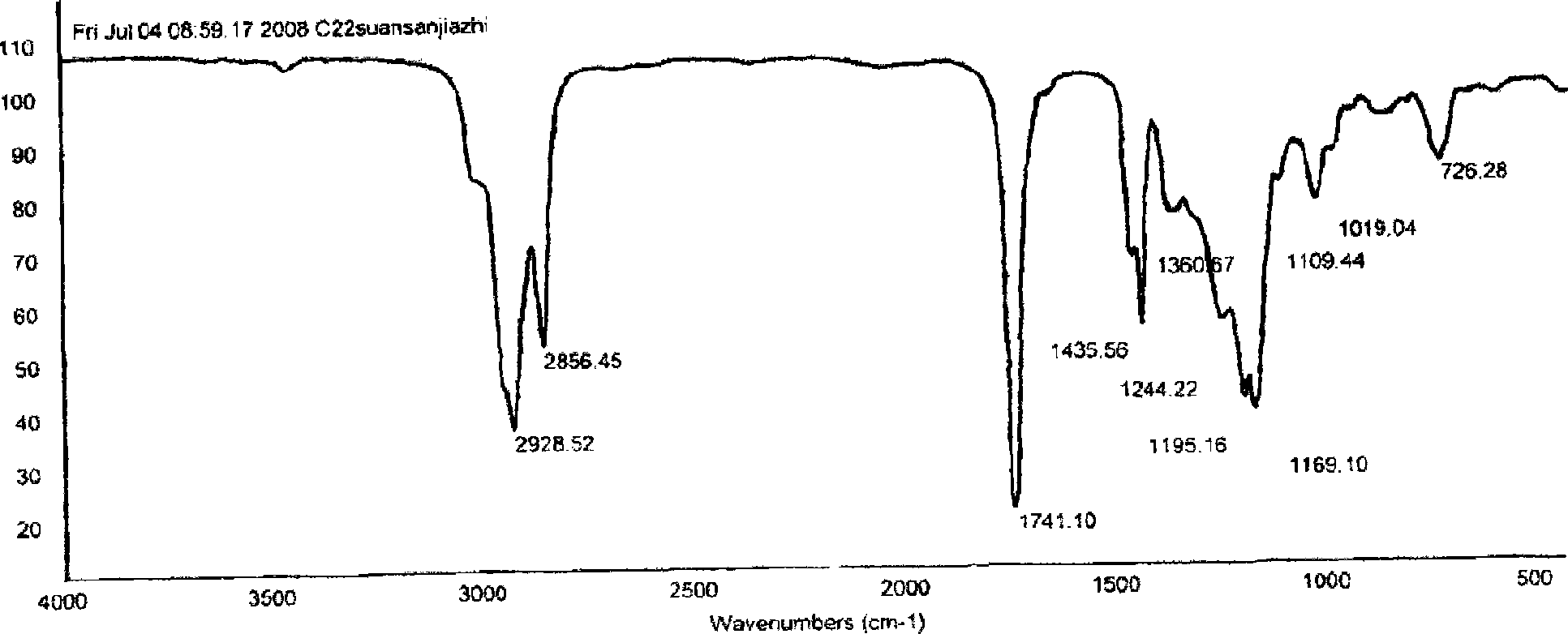

[0043] C 22 Trimethyl triacid plasticizer preparation

[0044] (1) Preparation of Methyl Caryonate

[0045] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120°C, dehydrate under reduced pressure for 1 to 2 hours to make the water content less than 0.2%, and cool to 50°C , add 260 grams of methanol and 5 grams of potassium hydroxide, react at 60-70°C for 4 hours, recover excess methanol, and cool to room temperature. Glycerin was separated, and after washing with water to remove the catalyst, free water and excess methanol were distilled off to obtain 280 grams of methyl lyceate.

[0046] (2) Synthesis of dimethyl maleate

[0047] In a 500ml three-necked flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a fractional distillation condenser, add 200 grams of maleic anhydride, 250 grams of methanol and 0.5 grams of sul...

Embodiment 2

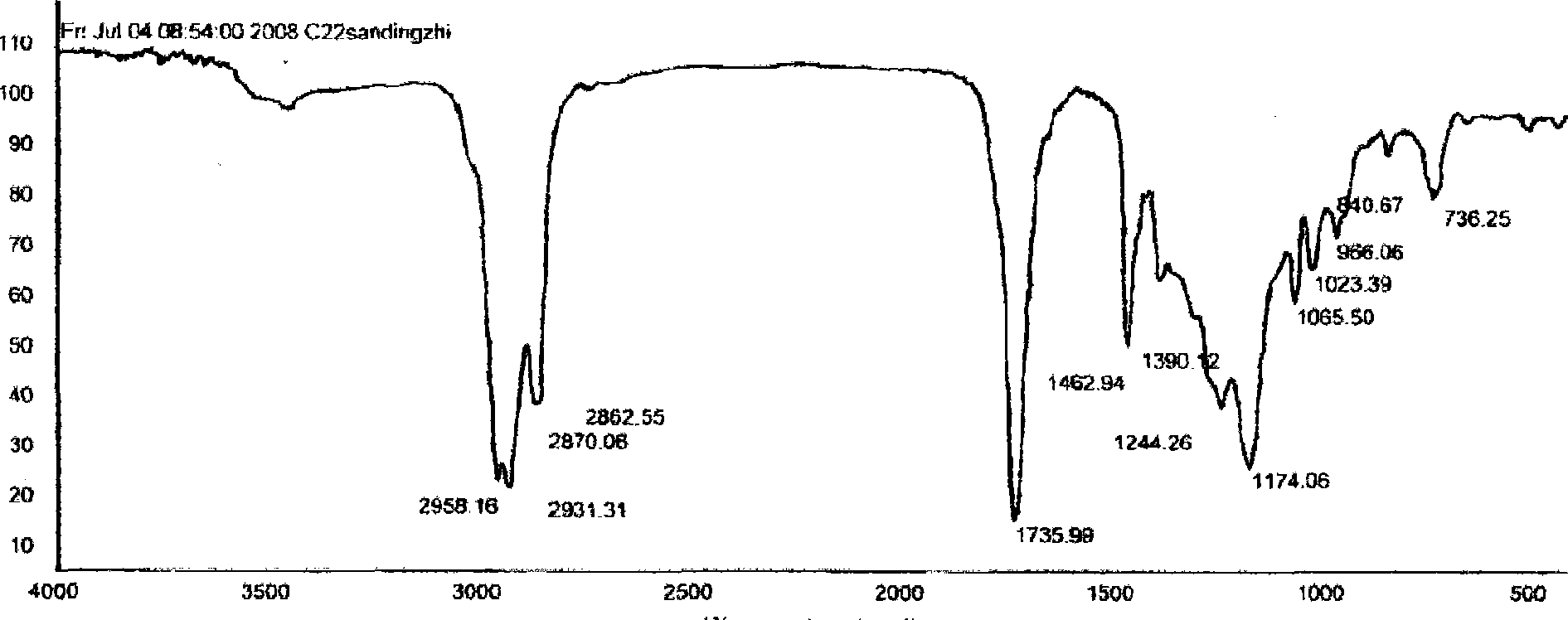

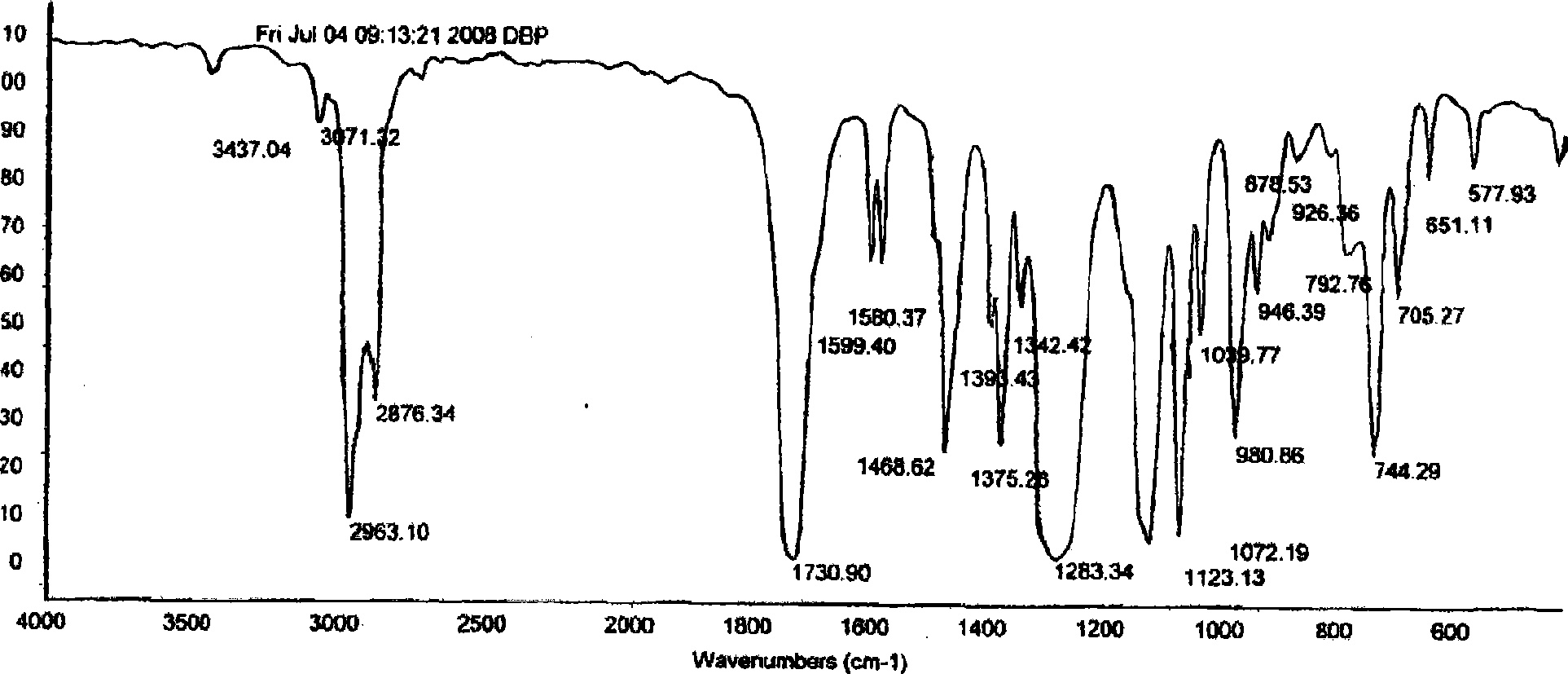

[0051] C 22 Preparation of dibutyl monomethyl triate

[0052] (1) Preparation of Methyl Caryonate

[0053] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120°C, dehydrate under reduced pressure for 1 to 2 hours to make the water content less than 0.2%, and cool to 50°C , add 260 grams of methanol and 5 grams of potassium hydroxide, react at 60-70°C for 4 hours, recover excess methanol, and cool to room temperature. Glycerin was separated, and after washing with water to remove the catalyst, free water and excess methanol were distilled off to obtain 280 grams of methyl lyceate.

[0054] (2) Synthesis of dibutyl maleate

[0055] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a fractional distillation condenser, add 200 grams of maleic anhydride, 400 grams of n-butanol and 6 grams of tetrabut...

Embodiment 3

[0059] C 22 Preparation of tributyl triacid plasticizer

[0060] (1) Preparation of butyl sulphonate

[0061] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a reflux condenser, add 298 grams of tung oil, heat to 120°C, dehydrate under reduced pressure for 1 to 2 hours to make the water content less than 0.2%, and cool to 50°C , add 360 g of butanol and 8 g of potassium hydroxide, react at 80-100° C. for 4 hours, recover excess butanol, and cool to room temperature. Glycerin was separated, and after washing with water to remove the catalyst, free water and excess butanol were distilled off to obtain 320 grams of butyl carnitate.

[0062] (2) Synthesis of dibutyl maleate

[0063] In a 500ml three-neck flask equipped with a constant temperature oil bath, a stirring device, a thermometer, and a fractional distillation condenser, add 200 grams of maleic anhydride, 400 grams of n-butanol and 6 grams of tetrabutyl t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com