Preparation method for reactive chitosan derivant

A technology of chitosan derivatives and reactivity, which is applied in the field of preparation of natural biopolymer materials, can solve the problems of complex process, high cost, and low degree of product substitution, and achieve simple experimental equipment, easy reaction process, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

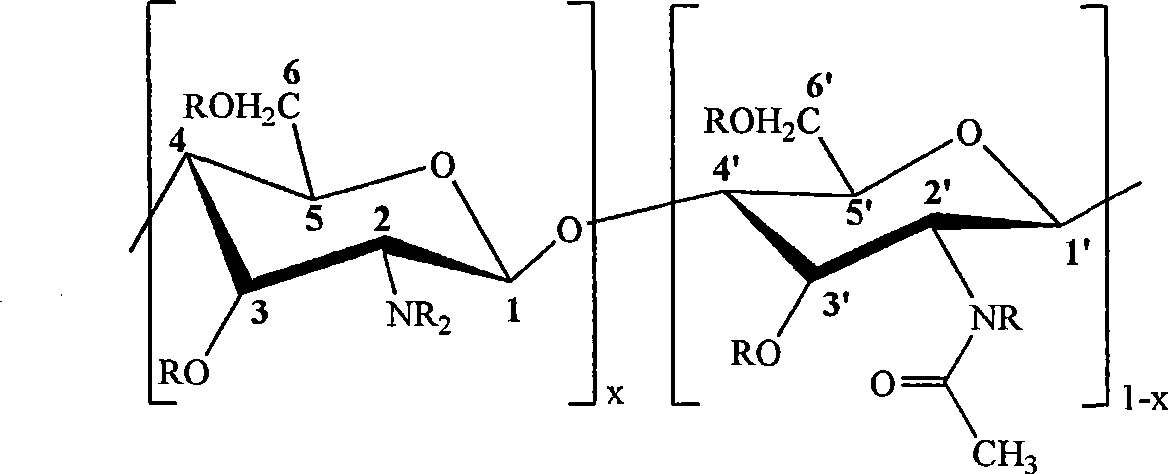

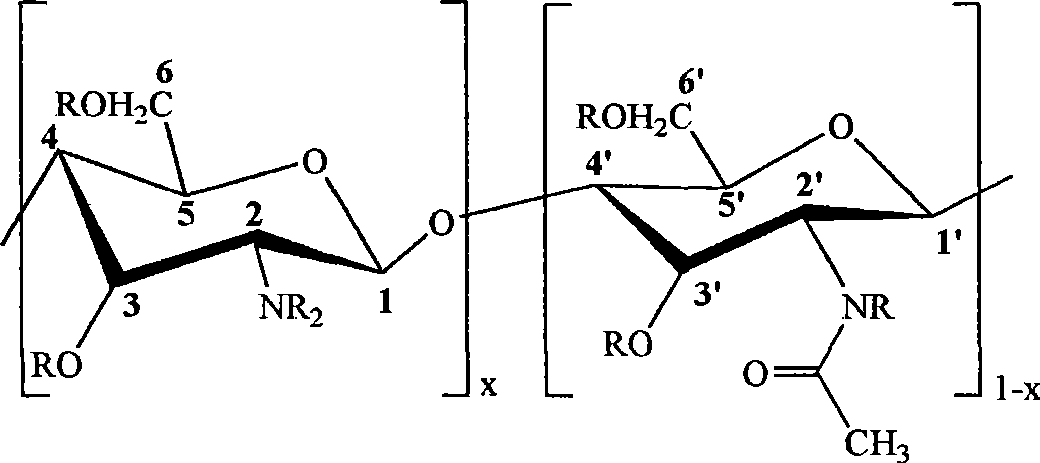

Image

Examples

Embodiment 1

[0023] Add 2.0g of chitosan (DP=85%, Mw=100,000) into 200mL of a solution of triethylamine and chloroform with a volume ratio of 1:1, stir at room temperature for 48 hours, and place it on ice at -5°C Cool and stir under the bath for 2 hours, dissolve 1.24g of methacryloyl chloride in 20mL of chloroform, stir evenly, slowly add it dropwise to the chitosan solution under the ice bath condition of -5°C, and react for 2 hours. Continue to react at normal temperature for 6 hours, and wash the filtered precipitate three times with acetone to obtain the reactive chitosan derivative.

Embodiment 2

[0025] Add 2.0 g of chitosan (DP=85%, Mw=100,000) to 200 mL of a solution of triethylamine and dichloromethane at a volume ratio of 1:1, stir at room temperature for 48 hours, and place it on ice at -5°C Cool and stir in the bath for 2 hours, dissolve 2.2g of acryloyl chloride in 30mL of dichloromethane, stir evenly, and slowly add it dropwise to the chitosan solution under the ice bath condition of -5°C, react for 3 hours, and continue to React at normal temperature for 6 hours, and wash the filtered precipitate three times with acetone to obtain the reactive chitosan derivative.

Embodiment 3

[0027] Add 2.0g of chitosan (DP=85%, Mw=200,000) to 200mL of a solution of ethylamine and dichloromethane at a volume ratio of 2:1, stir at room temperature for 48 hours, and place in an ice bath at -5°C Under cooling and stirring for 2 hours, dissolve 1.5g of acryloyl chloride in 20mL of dichloromethane, stir evenly, and slowly add it dropwise to the chitosan solution in an ice bath at -5°C, react for 3 hours, and continue to The reaction was carried out for 6 hours, and the filtered precipitate was washed three times with acetone to obtain the reactive chitosan derivative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com