Method for producing semi-reinforcing hydrocarbon black, methanol, liquid ammonia with coke oven gas

A technology for semi-reinforcing carbon black and coke oven gas, which is applied in the preparation/separation of ammonia, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of environmental pollution, waste of precious resources, etc. Short process route and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

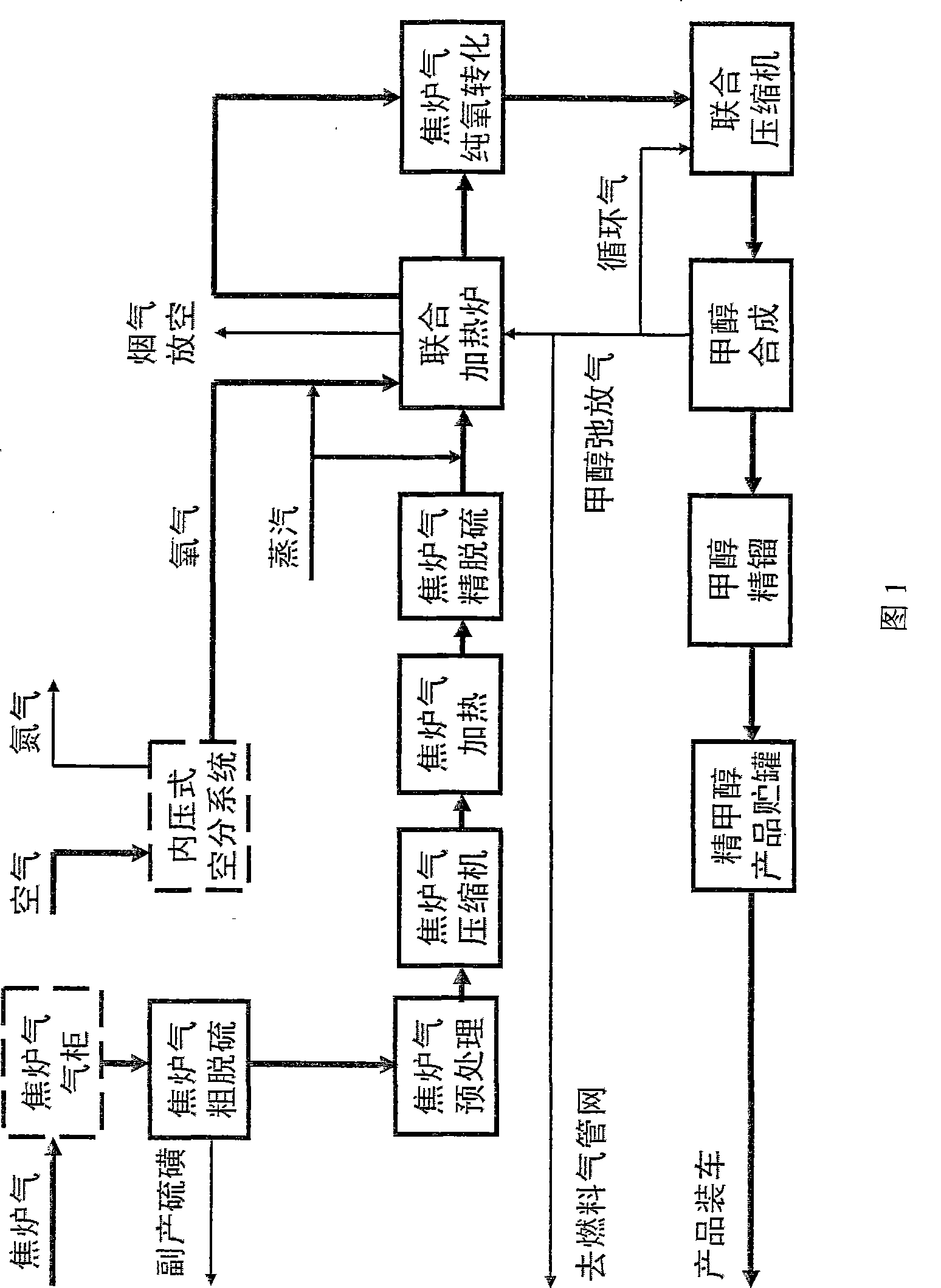

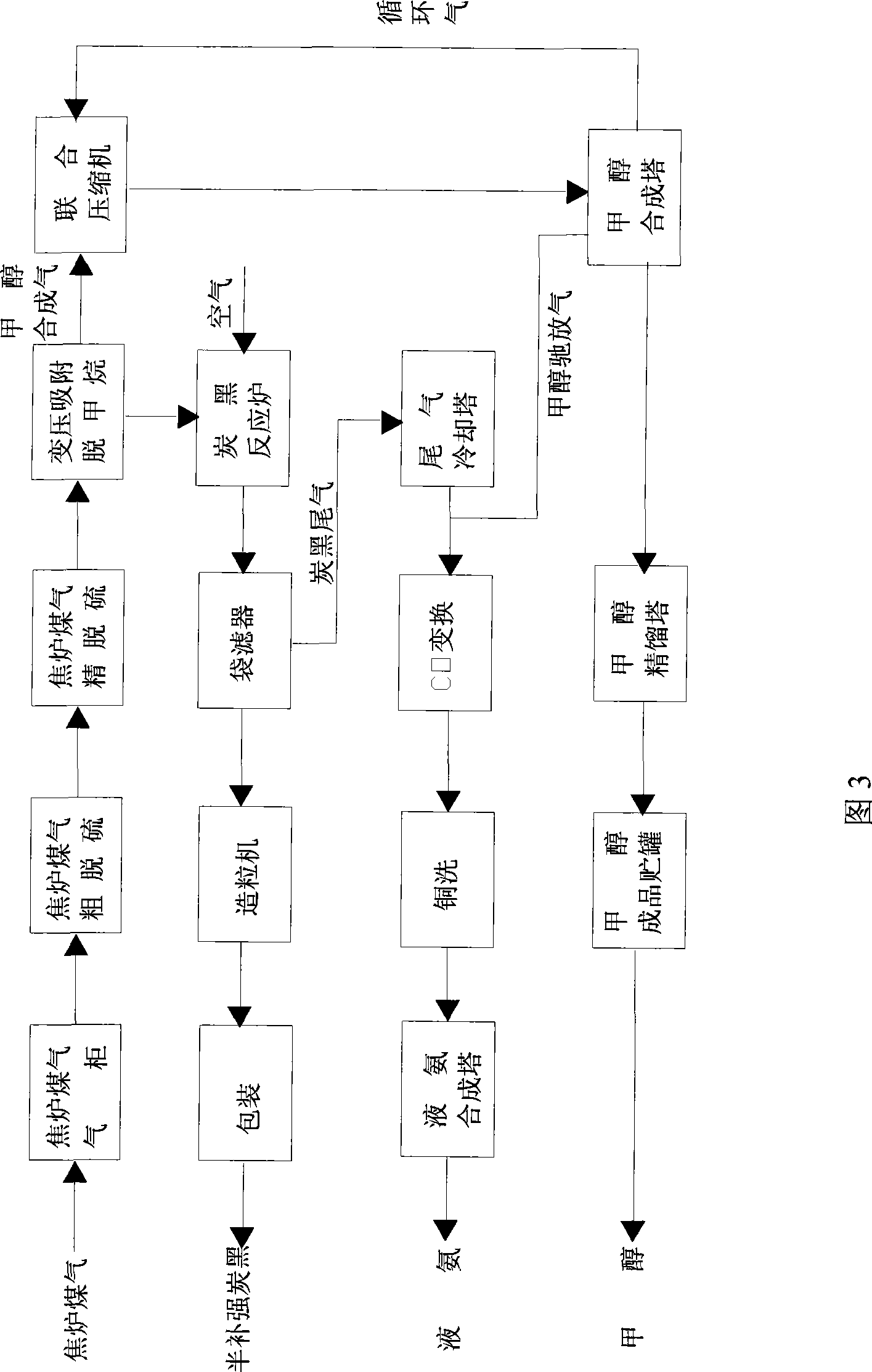

[0013] As shown in Figure 3, the pressure of the coke oven gas is about 2.45MPa (gauge pressure) after desulfurization, and the shift gas with a temperature of 40°C comes from the outside of the device and enters the adsorption tower from the bottom of the tower. Under the selective adsorption of various adsorbents (multiple adsorbents are included in the existing adsorption equipment), the methane in it is adsorbed, and the unadsorbed purified gas flows out from the top of the tower as methanol synthesis gas and is sent to the combined compression machine. Its methane content is less than 1%, and its pressure is 2.40MPa. Methane gas with a concentration of not less than 70% enters the carbon black reaction furnace, and the air with a flow rate of 20m / s is used as the oxidant. The ratio of methane gas to air is 1:2~3, and carbon black is generated in the carbon black reaction furnace. The reaction temperature is 1100℃~1300℃, after the reaction, the carbon black gas passes thr...

Embodiment 2

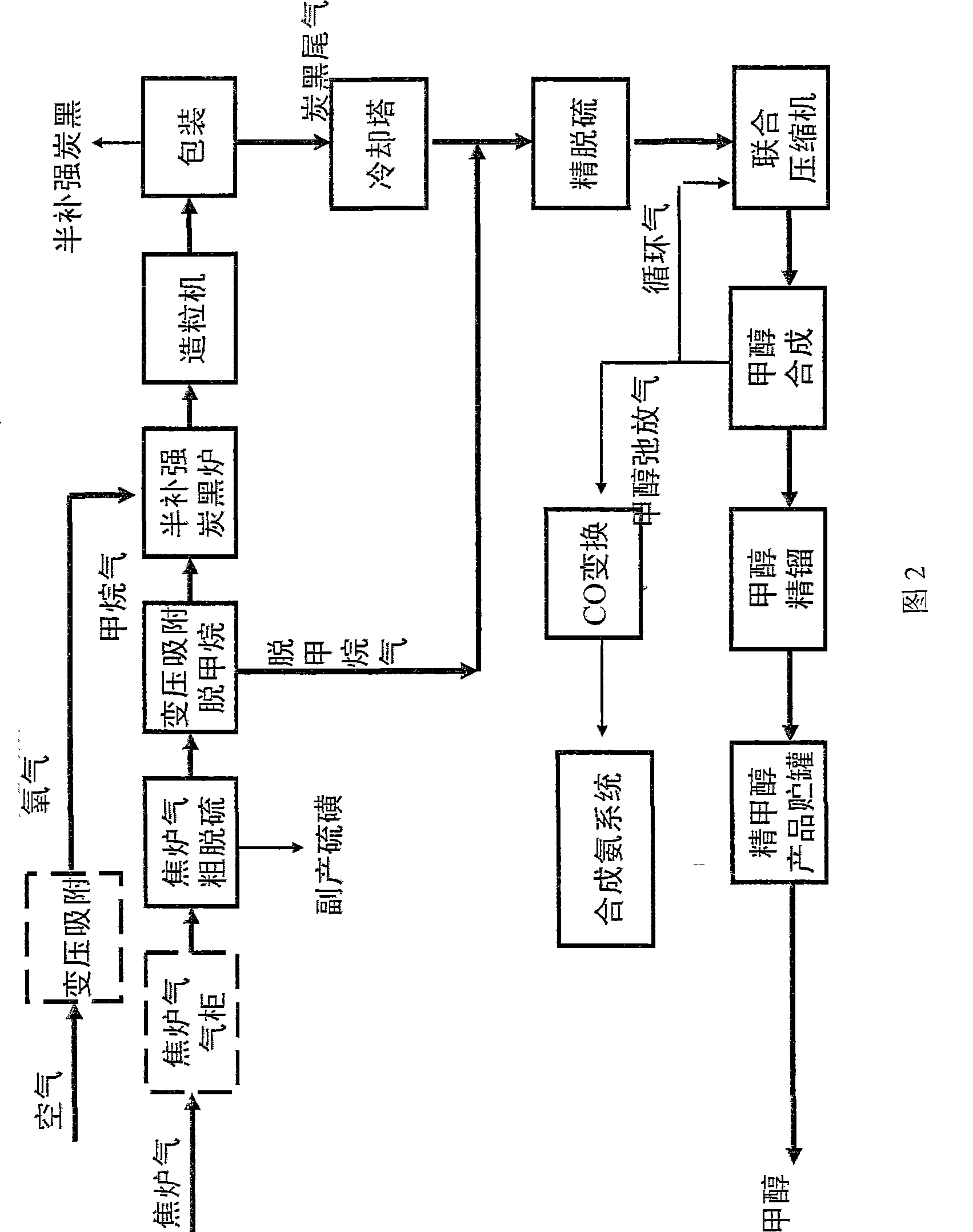

[0015] As shown in Figure 4, the coke oven gas is pressurized at about 2.45MPa (gauge pressure) after desulfurization, and the shift gas with a temperature of 40°C comes from the outside of the device and enters the adsorption tower from the bottom of the tower. Under the selective adsorption of various adsorbents, the methane in it is adsorbed, and the unadsorbed purified gas flows out from the top of the tower as methanol synthesis gas and is sent to the combined compressor. Its methane content is less than 1%, and its pressure is 2.40MPa. Methane gas with a concentration of not less than 70% enters the carbon black reaction furnace, and oxygen with a purity of 93% is added at a flow rate of 20m / s as an oxidant. The ratio of methane gas to oxygen is 1:0.5, and carbon black is generated in the carbon black reaction furnace. The reaction temperature is 1100℃~1300℃. After the reaction, the carbon black gas passes through the bag filter to obtain carbon black and carbon black ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com