Preparation of sheet zinc oxide

A zinc oxide, flake technology, applied in the direction of zinc oxide/zinc hydroxide, can solve the problems of less ZnO and less attention to properties, and achieve the effects of low synthesis temperature, low price and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 1.84g of anhydrous zinc acetate and 50ml of glycerin, mix well, then heat at 300°C for 30min, take out, and cool naturally to room temperature.

[0024] 2) washing with distilled water, centrifuging several times, and drying to obtain a flaky glycerol zinc precursor.

[0025] 3) The above products were respectively placed in a muffle furnace, and heated at 400, 500, and 600° C. for 1 hour to obtain flaky ZnO products.

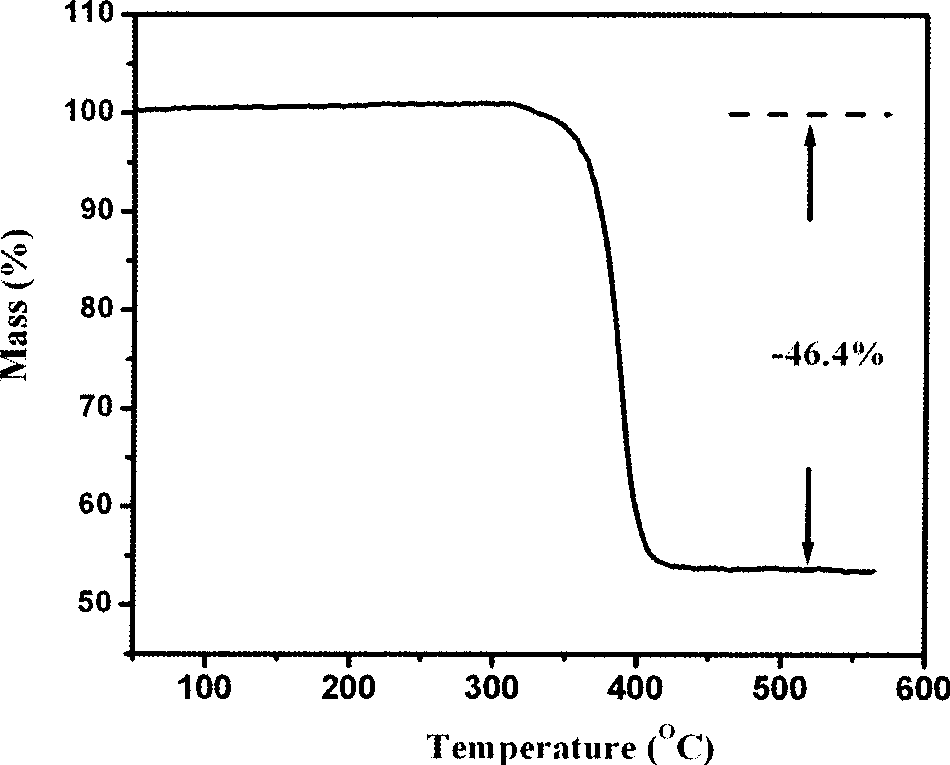

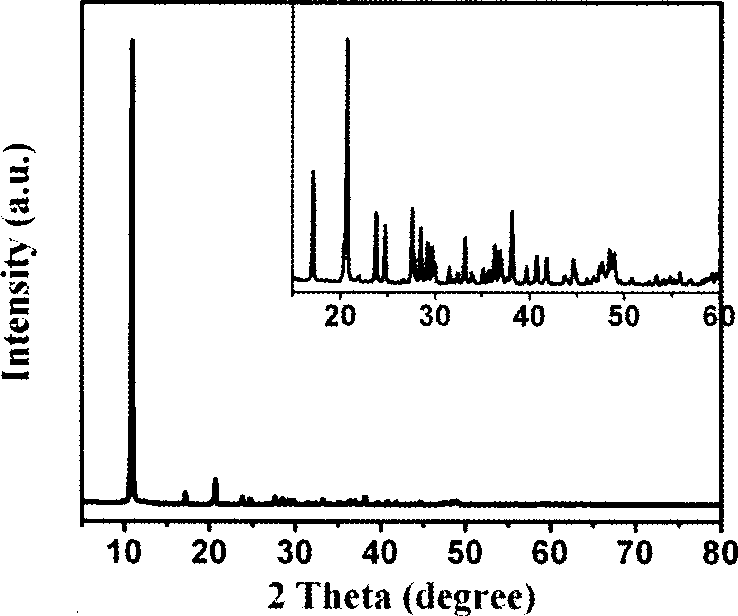

[0026] Perform XRD, SEM, TG, PL and other characterizations on the precursors and final products, and perform thermogravimetric analysis on the precursors (such as figure 1 ) found that at 370°C, the precursor began to decompose. XRD and SEM analysis (such as figure 2 and 3 ) It can be seen that the precursor is a flaky structure, and the XRD pattern of the sample is completely consistent with the XRD pattern of the standard zinc glycerol, indicating that the precursor is zinc glycerol. In the sample XRD, it can also be seen that the diffra...

Embodiment 2

[0031] 1) Weigh 0.37g of anhydrous zinc acetate and 10ml of glycerin, mix well, then heat at 350°C for 1h, take out, and cool naturally to room temperature.

[0032] 2) washing with distilled water, centrifuging several times, and drying to obtain a flaky glycerol zinc precursor.

[0033] 3) Take the above products and place them in a muffle furnace, and heat them at 400, 500, and 600° C. for 1 hour, and the flaky ZnO products can also be obtained.

Embodiment 3

[0035] 1) Weigh 1g of anhydrous zinc acetate and 10ml of glycerin, mix well, then heat at 350°C for 1 hour, take it out, and let it cool down to room temperature naturally.

[0036] 2) washing with distilled water, centrifuging several times, and drying to obtain a flaky glycerol zinc precursor.

[0037] 3) Take the above products and place them in a muffle furnace, and heat them at 400, 500, and 600° C. for 1 hour, and the flaky ZnO products can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com