Method for coproduction of dispersants MF and sodium sulphite

A sodium sulfite and dispersant technology, applied in the field of preparation of sulfonated dispersants, can solve the problems of complex process, large equipment investment, high cost, etc., and achieve the effects of simple process, low energy consumption, and low content of calcium and magnesium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

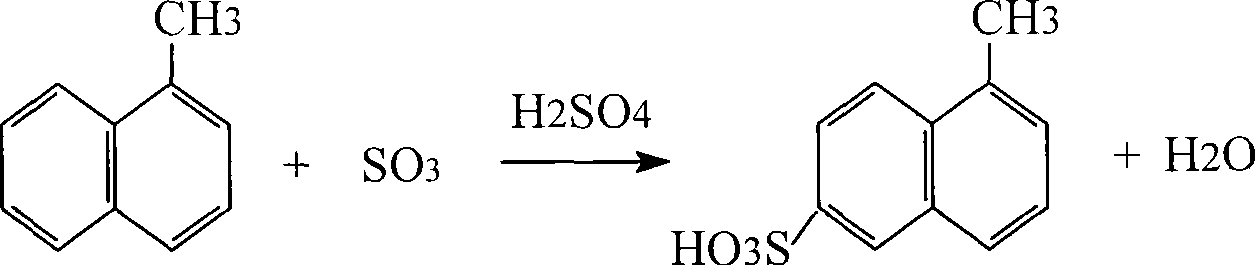

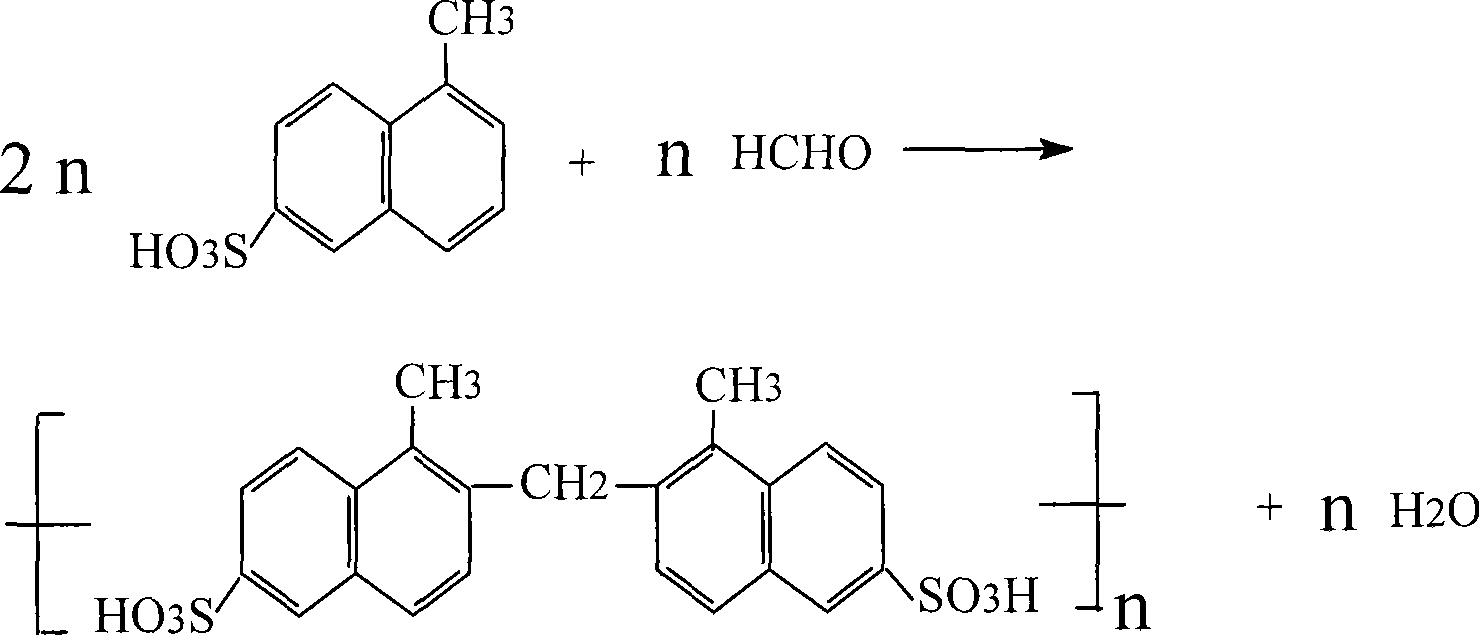

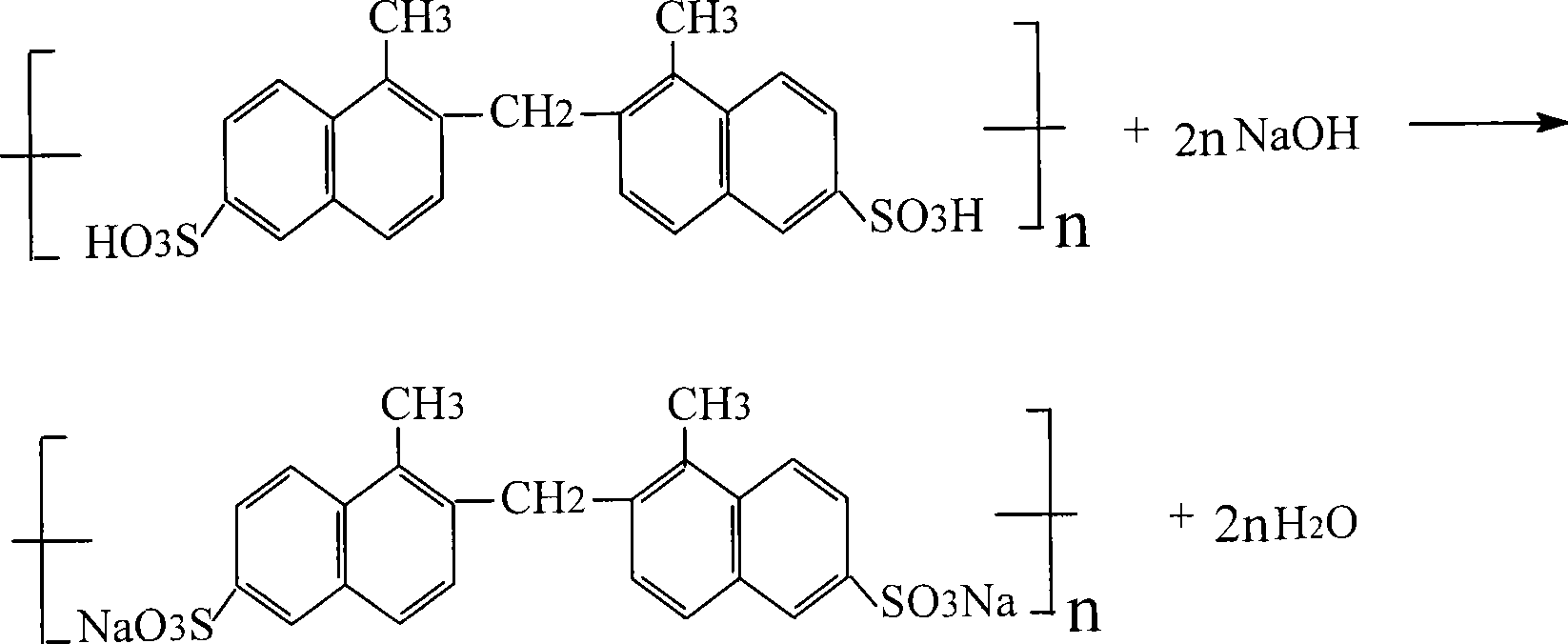

Method used

Image

Examples

Embodiment 1

[0021] Put 60g of industrial methylnaphthalene into the reaction vessel, add 23g of 98% concentrated sulfuric acid, stir evenly, then slowly pass in about 25g of sulfur trioxide gas, control the reaction temperature at 50-60°C, and control the passage time at 1-2 Hours, pass through, heat preservation reaction for 1 hour, heat up to 150°C, vacuumize, control the vacuum degree at about 0.025Mpa, react at this temperature for 3 hours, then take samples to measure the acid value, after the acidity is qualified, cool down to 110°C, Add a certain amount of water to adjust the condensation acidity to 18%, then lower the temperature to 70°C and add 27g of formaldehyde solution (general concentration is 36% to 38%), heat up to 110°C and pressurize for 5 hours, then lower the temperature and pressure, add water to dilute , add sodium hydroxide to adjust the pH value to neutral, and obtain the aqueous solution of dispersant MF, and dry it to obtain solid powder MF.

[0022] The sulfur d...

Embodiment 2

[0024] Put 60g of washing oil into the reaction container, add 24g of 98% concentrated sulfuric acid, stir evenly, then slowly feed about 26g of sulfur trioxide gas, control the reaction temperature at 70-80°C, and control the feeding time at 2-3 hours, After passing through, keep warm for 1 hour, start to heat up to 140°C, vacuumize, control the vacuum degree at about 0.02Mpa, react at this temperature for 3 hours, then take samples to measure the acid value, after the acidity is qualified, cool down to 100°C, add certain amount of water, adjust the condensation acidity to 20%, then lower the temperature to 70°C, add 26g of formaldehyde solution (general concentration is 36%~38%), raise the temperature to 110°C and pressurize for 5 hours, then lower the temperature and reduce the pressure, add water to dilute, add Adjust the pH value to neutral with sodium hydroxide to obtain the aqueous solution of dispersant MF, and dry it to obtain solid powder MF.

[0025] The sulfur diox...

Embodiment 3

[0027] Put 60g of industrial methylnaphthalene into the reaction vessel, add 24g of 98% concentrated sulfuric acid, stir evenly, then slowly pass in about 24g of sulfur trioxide gas, control the reaction temperature at 80-90°C, and control the passage time at 2-3 Hours, pass through, heat preservation reaction for 1 hour, start to heat up to 145°C, vacuumize, control the vacuum degree at about 0.03Mpa, react at this temperature for 3 hours, then take samples to measure the acid value, after the acidity is qualified, cool down to 110°C, Add a certain amount of water to adjust the condensation acidity to 15%, then lower the temperature to 70°C and add 28g of formaldehyde solution (general concentration is 36% to 38%), heat up to 110°C and pressurize for 5 hours, then lower the temperature and pressure, add water to dilute , add sodium hydroxide to adjust the pH value to neutral, and obtain the aqueous solution of dispersant MF, and dry it to obtain solid powder MF.

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com