Microwave plasma flare waveguide excitation cavity

A technology of microwave plasma and excitation cavity, which is applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of complex structure and increased cost, and achieve stable work, high utilization rate, high electron temperature and electron density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

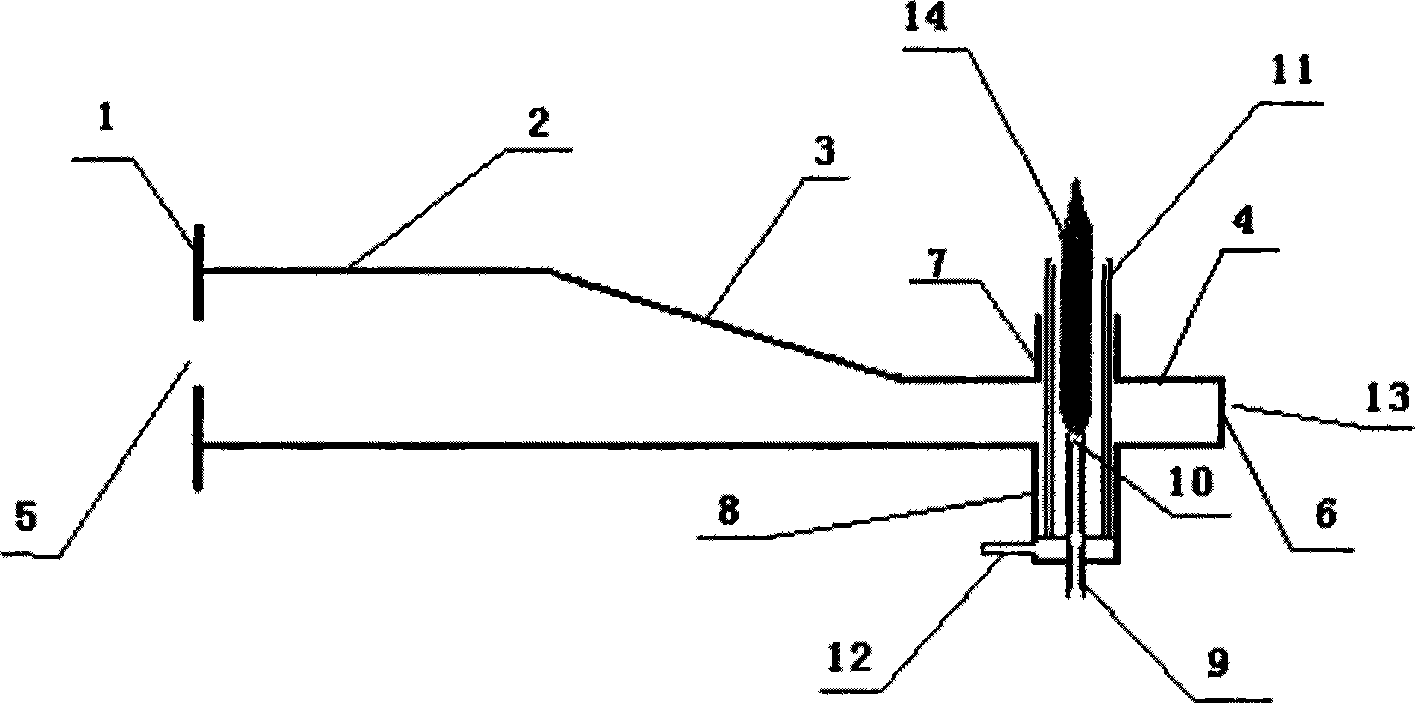

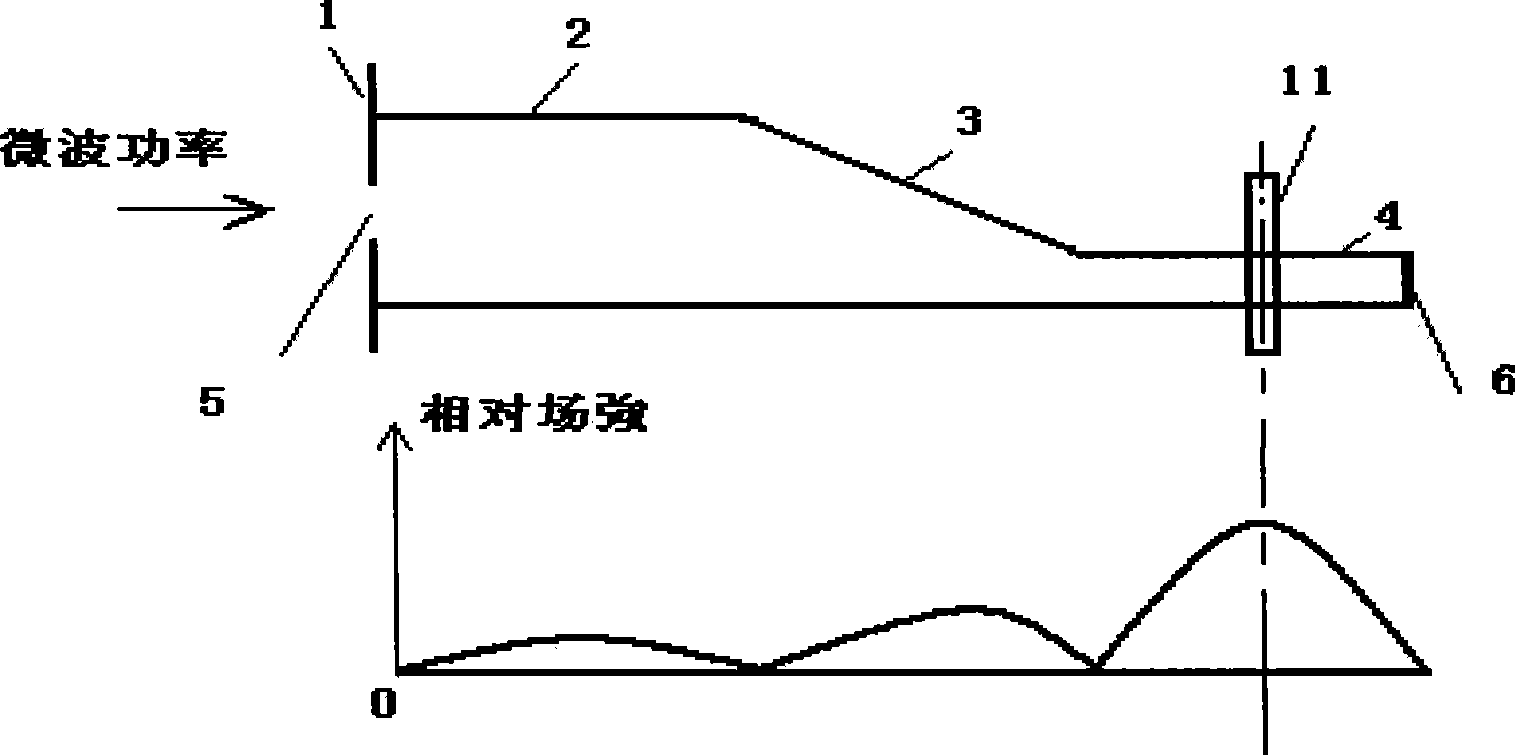

[0014] Attached below figure 1 And the implementation case will further illustrate the present invention.

[0015] The structure diagram of the implementation case of the present invention is as follows figure 1 As shown, it includes the waveguide flange 1, the first section of rectangular waveguide 2, the second section of rectangular tapered waveguide 3, the third section of highly compressed narrow waveguide 4, the perforated metal diaphragm 5, the metal short-circuit plate 6, and the top of the narrow waveguide Cylinder 7, the outer conductor of the coaxial line at the bottom of the narrow waveguide 8, the inner conductor of the coaxial line at the bottom of the narrow waveguide 9, the metal nozzle 10, the quartz glass tube 11, the bottom tangential air inlet 12, and the observation hole 13 at the center of the short-circuit board , Generated plasma torch 14.

[0016] The specific parameter sizes of each part of this implementation case are described as follows:

[0017] This ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com