ZrB2/W nano multilayer film and preparation method thereof

A nano-multilayer, multi-layer film technology, applied in the direction of coating, layered products, metal material coating process, etc., can solve the problems of no report, high melting point chemical stability, etc., to improve mechanical properties and enhance bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

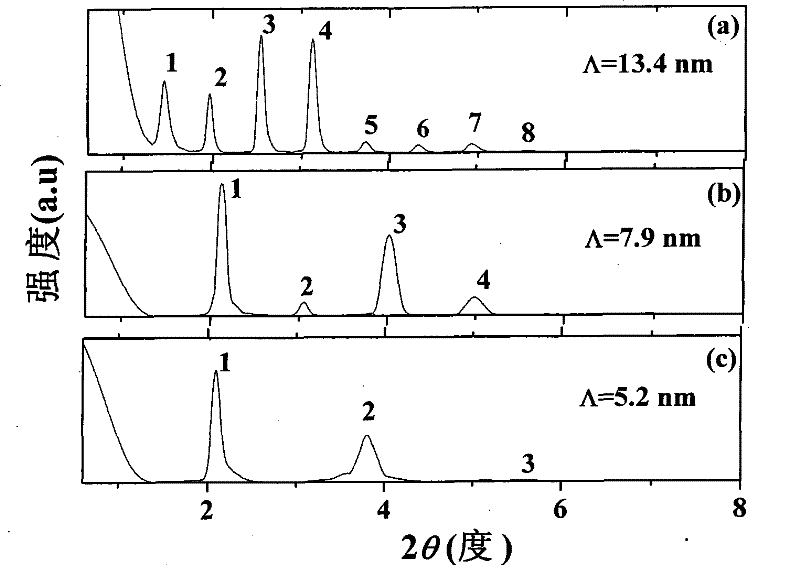

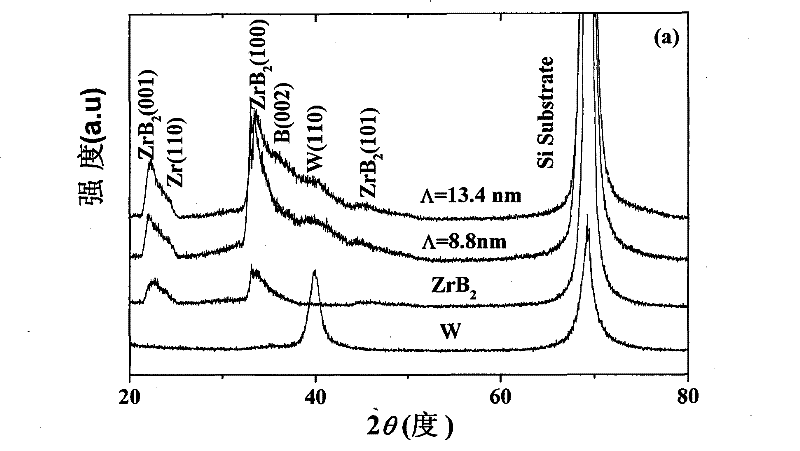

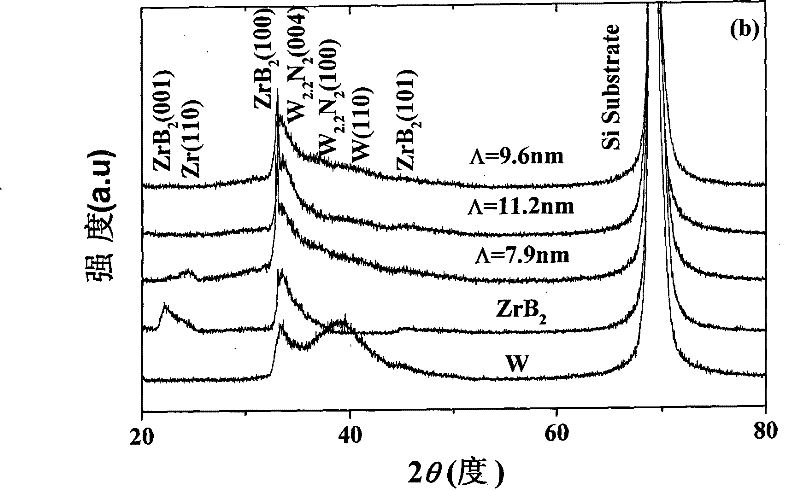

Image

Examples

Embodiment

[0047] use N 2 Synthesis of ZrB with Auxiliary Combination of Substrate Heating Conditions 2 / W Nano multilayer film:

[0048] (1) Before the experiment, the Si wafers were ultrasonically cleaned with acetone and absolute alcohol for 15 minutes, dried and put into the ion beam assisted deposition coating chamber.

[0049] (2) Vacuum the chamber so that the background vacuum in the chamber is 2.0×10 -4 Pa.

[0050] (3) Open the air inlet of the auxiliary chamber, control the Ar inlet flow rate with a mass flow meter to keep it at 4.5 sccm, adjust the discharge voltage to 70V, the acceleration voltage is 100V, the auxiliary energy is 500eV, and the auxiliary beam current is 5mA, The sample was bombarded and cleaned for at least 5 min with an Ar ion beam.

[0051] (4) Open the air inlet of the sputtering chamber, control the Ar intake flow rate with a mass flow meter, keep it at 4.5sccm, adjust the discharge voltage to 70V, the acceleration voltage is 200V, and the sputtering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com