Building material based on interaction of alkali and CO2

A CO2, synergistic technology, applied in the field of silicate building materials and products, to achieve the effect of reducing carbonation depth requirements, reducing CO2 emissions, and relaxing the parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of silicate building material product of the present invention, comprises the following steps:

[0034] 1. Grinding: Grinding fly ash and slag to the set fineness;

[0035] 2. Mixing: Mix fly ash and slag evenly according to the ratio requirements;

[0036] 3. Stirring: Add aggregate and appropriate amount of water glass to the evenly mixed powder and stir thoroughly;

[0037] 4. Injection molding: Immediately inject the fully stirred slurry into a test mold of a certain shape to obtain a green body;

[0038] 5. Curing: natural curing of the green body at room temperature;

[0039] 6. Carbonization: Put the green body into the carbonization device to carbonize to obtain the finished product.

[0040] In the above steps, the natural maintenance of the green body at room temperature is to make the mixed water glass exert its stimulating effect, and make the silicon and aluminum minerals in the fly ash and slag react to form a gelling substance th...

Embodiment 1

[0044] Take fly ash and slag and grind them to 550m 2 / Kg, 550m 2 / Kg.

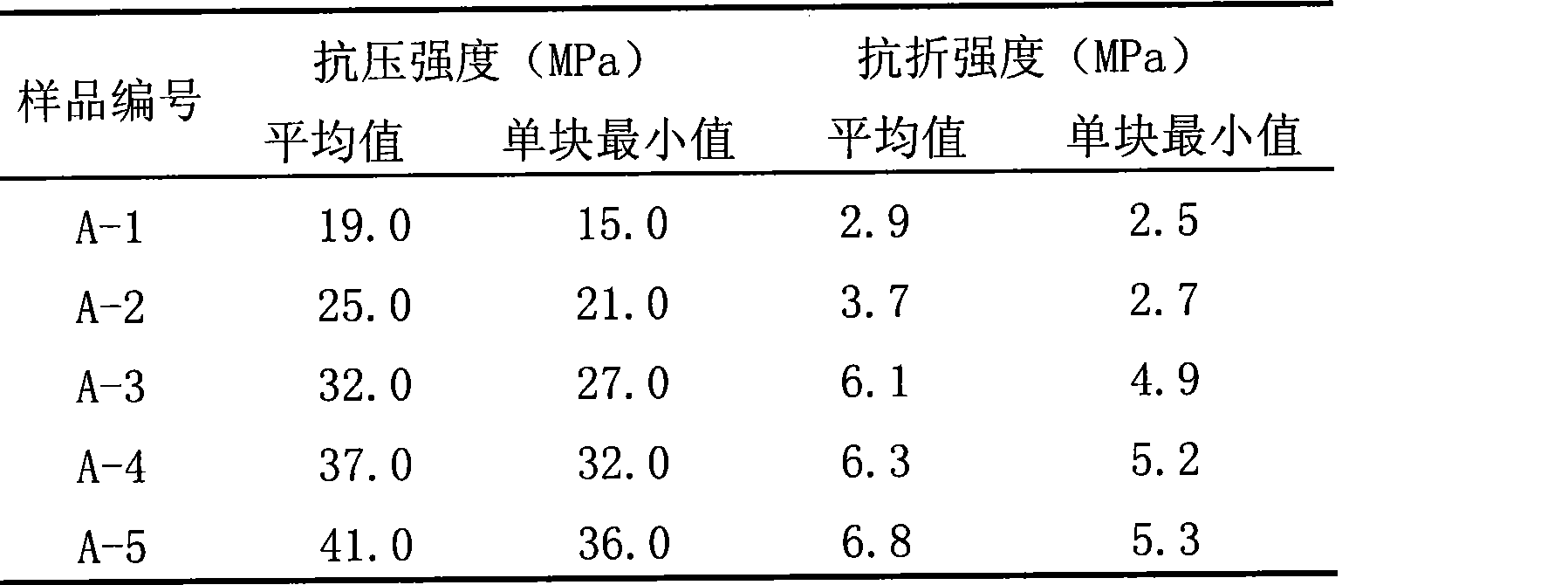

[0045] Get 70Kg pulverized coal ash and 30Kg pulverized slag and mix uniformly to obtain powder A-1; Get 60Kg pulverized coal ash and 40Kg pulverized slag and mix uniformly to obtain powder A-2; Get 50Kg ground pulverized coal ash and Mix 50Kg of finely ground slag uniformly to obtain powder A-3; take 40Kg of finely ground fly ash and mix uniformly with 60Kg of finely ground slag to obtain powder A-4; take 30Kg of finely ground fly ash and 70Kg of Material A-5.

[0046] In powder A-1, A-2, A-3, A-4, A-5 respectively, add sand (aggregate) 40Kg and water glass (alkali activator) 10Kg (accounting for 40% of powder weight respectively and 10%), fully stirred and shaped to obtain standard brick bodies A-1, A-2, A-3, A-4, A-5 (multiple pieces are prepared for each type), and the green bodies are naturally maintained for 1 day and then placed in temperature 60°C, 50% relative humidity, CO 2 Carbonize in a c...

Embodiment 2

[0051] Grind fly ash and slag to 450m 2 / Kg, 450m 2 / Kg. According to the weight ratio of 70%:30%, the ground fly ash and the ground slag are evenly mixed to obtain the powder material for use.

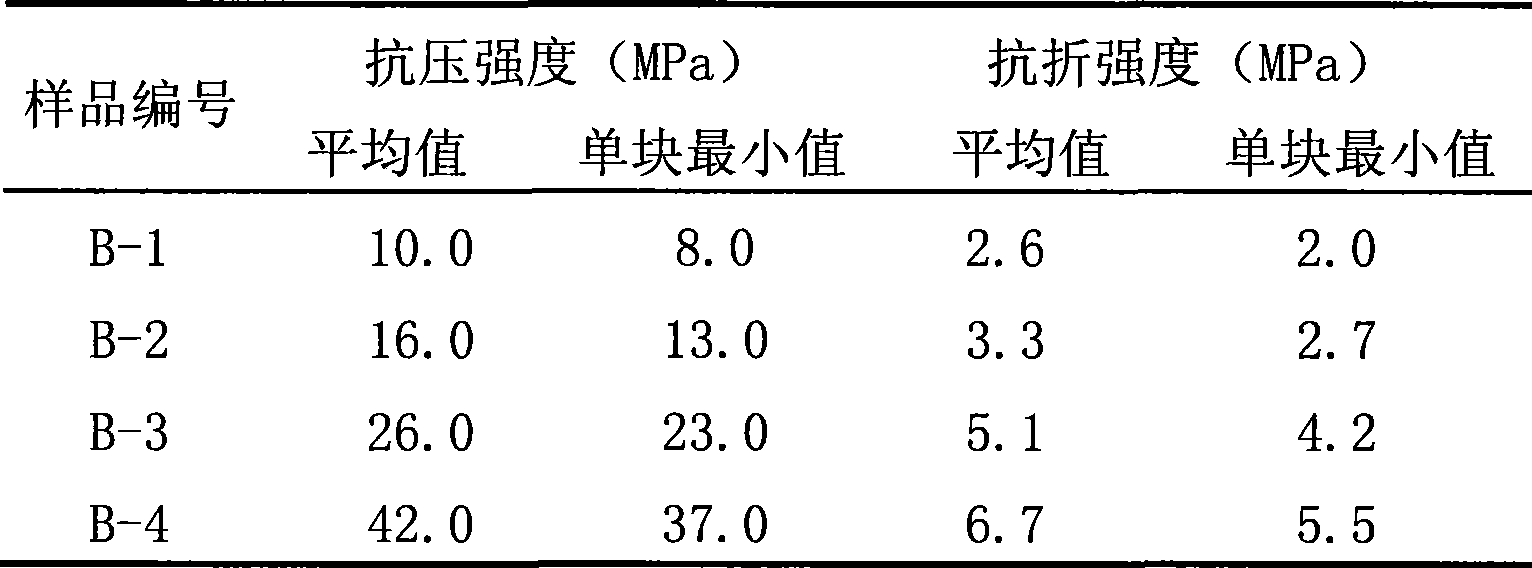

[0052] Take the same amount of powder (about 2 kg each), and then operate as follows: add aggregate and alkali activator to the powder according to the ratio of sand and water glass to 25% and 5% of the weight of the powder respectively , fully stirred and shaped to obtain the standard brick body B-1; according to the ratio of sand and water glass to 25% and 10% of the powder weight respectively, add aggregate and alkali activator to the powder, fully stir and shape to obtain the standard Brick body B-2; according to the ratio of sand and water glass to 25% and 15% of the powder weight respectively, add aggregate and alkali activator to the powder, fully stir and shape to obtain standard brick body B-3; press Sand and sodium silicate account for 25% and 20% of the weight of the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com