High selectivity hygroscopic agent with shell and core structure and preparation method thereof

A highly selective, nuclear-structured technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of low hygroscopic capacity, small adsorption capacity, poor selectivity, etc., and achieve low cost, high hygroscopic capacity, Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

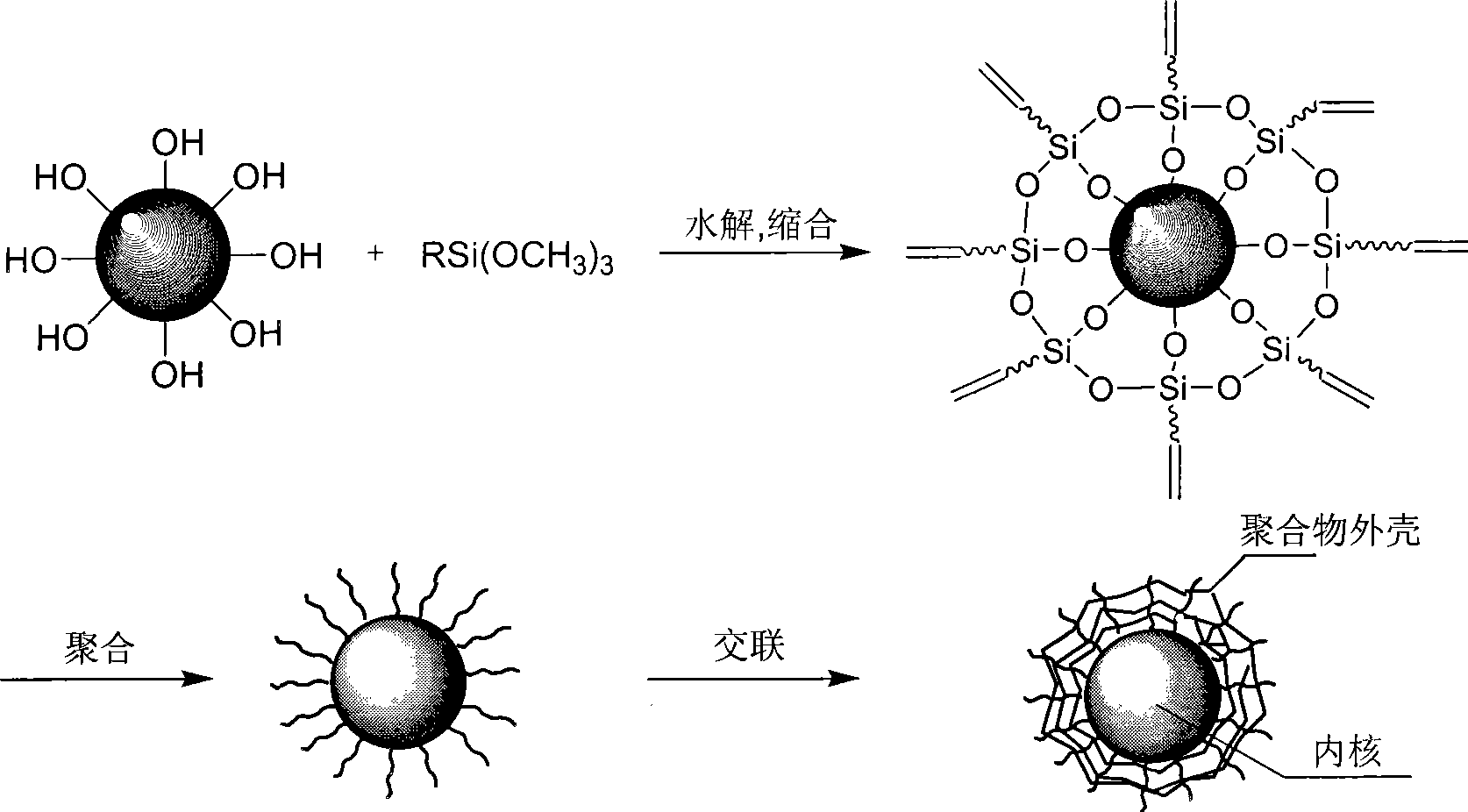

Method used

Image

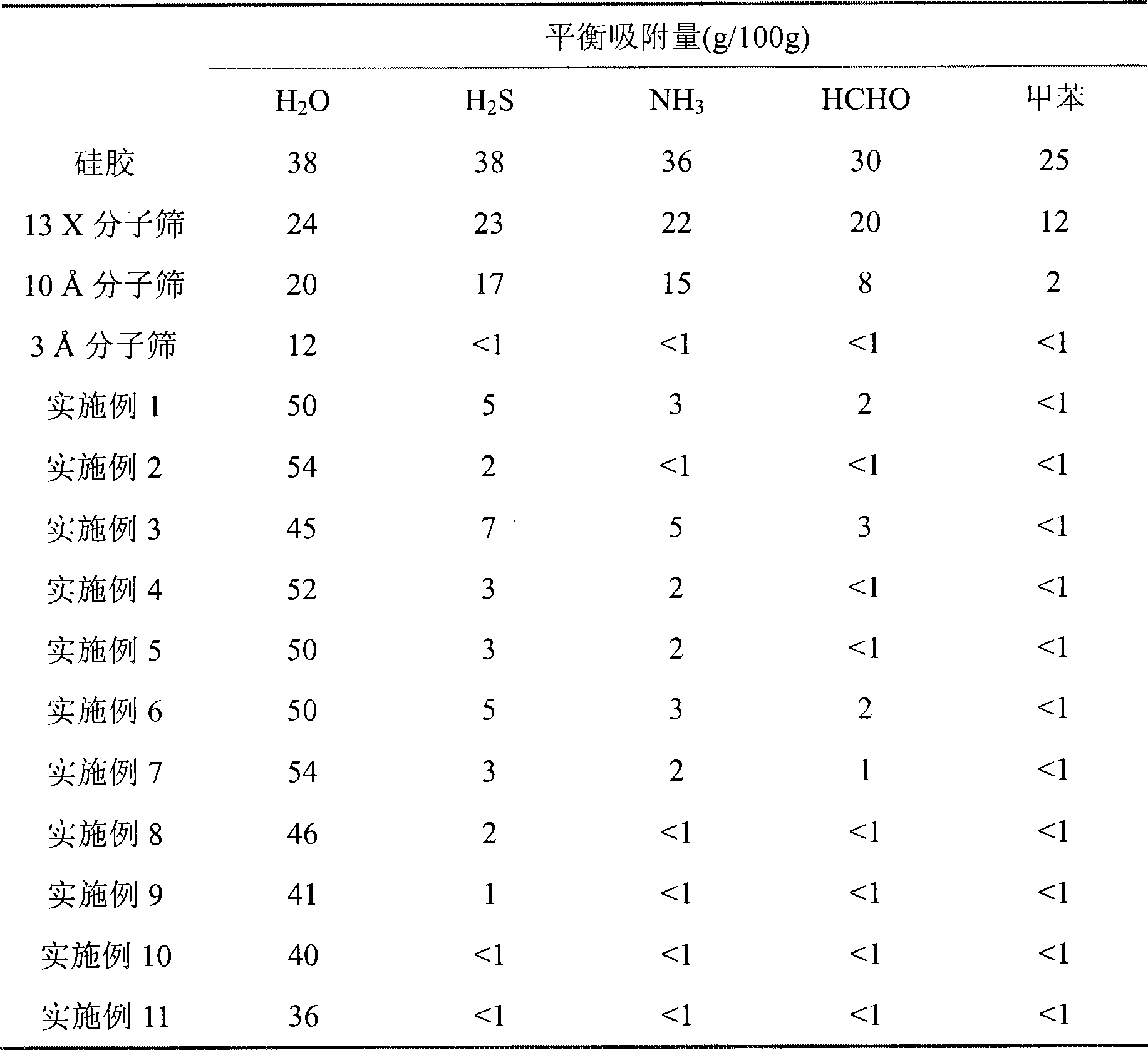

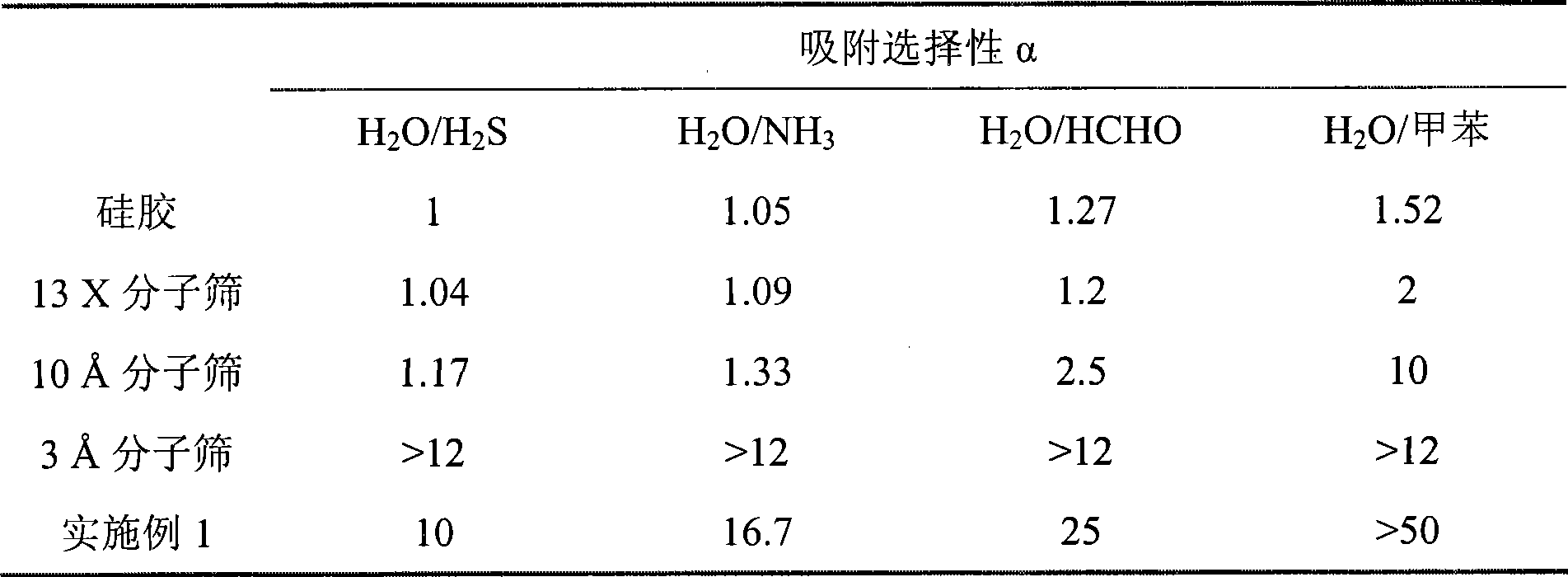

Examples

Embodiment 1

[0026] Activate 10g of 100-200 mesh silica gel in 150mL of 5% (mass concentration) methanesulfonic acid aqueous solution at 100°C for 6h, then add to 200mL of 4% ethanol solution of 3-(methacryloyloxy)propyltrimethoxysilane , stirred and reacted at 30°C for 24h, the reaction mixture was filtered, washed with ethanol, and dried to obtain silica gel MA-SiO with double bonds on the surface 2 ;

[0027] The resulting MA-SiO 2 Add it to 200mL of 6% (mass concentration) aqueous solution of methacrylic acid, add 0.12g ammonium persulfate under stirring to initiate the polymerization reaction, react at 30°C for 20h, filter the reaction mixture, wash with ethanol, and obtain surface grafting after drying Polymer brushed silicone PMA-SiO 2 ;

[0028] The resulting PMA-SiO 2 Add ethylenediamine (0.3g, 5mmol) into a water-ethanol (volume ratio of water to ethanol: 9:1) solution, react for 6h under stirring at room temperature, filter, wash with water, wash with ethanol, and vacuum dry...

Embodiment 2

[0030] 10g of 100-200 mesh silica gel was activated in 200mL of 8% (mass concentration) methanesulfonic acid aqueous solution at 100°C for 10h, and then added to 200mL of 8% (mass concentration) of 3-(methacryloyloxy)propyltrimethoxy In the ethanol solution of silane, stir and react at 50°C for 18h, the reaction mixture is filtered, washed with ethanol, and dried to obtain the silica gel MA-SiO with double bonds on the surface 2 ; The resulting MA-SiO 2Add it to 200mL of 10% acrylic acid aqueous solution, add 0.2g potassium persulfate under stirring to initiate the polymerization reaction, react at 30°C for 15h, filter the reaction mixture, wash with ethanol, and dry to obtain the silica gel PMA with polymer brush on the surface -SiO 2 ; The resulting PMA-SiO 2 Add butanediamine (0.88g, 10mmol) into a water-ethanol (volume ratio of water to ethanol: 5:1) solution, react at room temperature for 10h, filter, wash with water / ethanol, and vacuum dry to obtain high Selective hyg...

Embodiment 3

[0032] Activate 5g of 100-200 mesh silica gel in 80mL of 3% (mass concentration) methanesulfonic acid aqueous solution at 100°C for 3h, then add to 100mL of 1% ethanol solution of 3-(methacryloyloxy)propyltrimethoxysilane , stirred and reacted at 70°C for 6h, and the reactant was filtered, washed with ethanol, and dried to obtain silica gel MA-SiO with double bonds on the surface 2 ; The resulting MA-SiO 2 Add it to 100mL of 2% acrylic acid-hydroxyethyl methacrylate (the mass ratio of acrylic acid to hydroxyethyl methacrylate is 3:1), and add 0.004g ammonium persulfate under stirring to initiate the polymerization reaction. After reacting for 5h, the resulting solid was filtered, washed with ethanol, and dried to obtain the silica gel PMA-SiO with surface grafted polymer brushes. 2 ; The resulting PMA-SiO 2 Add ethylenediamine (0.03g, 0.5mmol) into a water-ethanol (volume ratio of water to ethanol: 10:1) solution, react at room temperature for 4h, filter, wash with water / eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com