Passivation film of composite semiconductor silicon device and passivation generating process

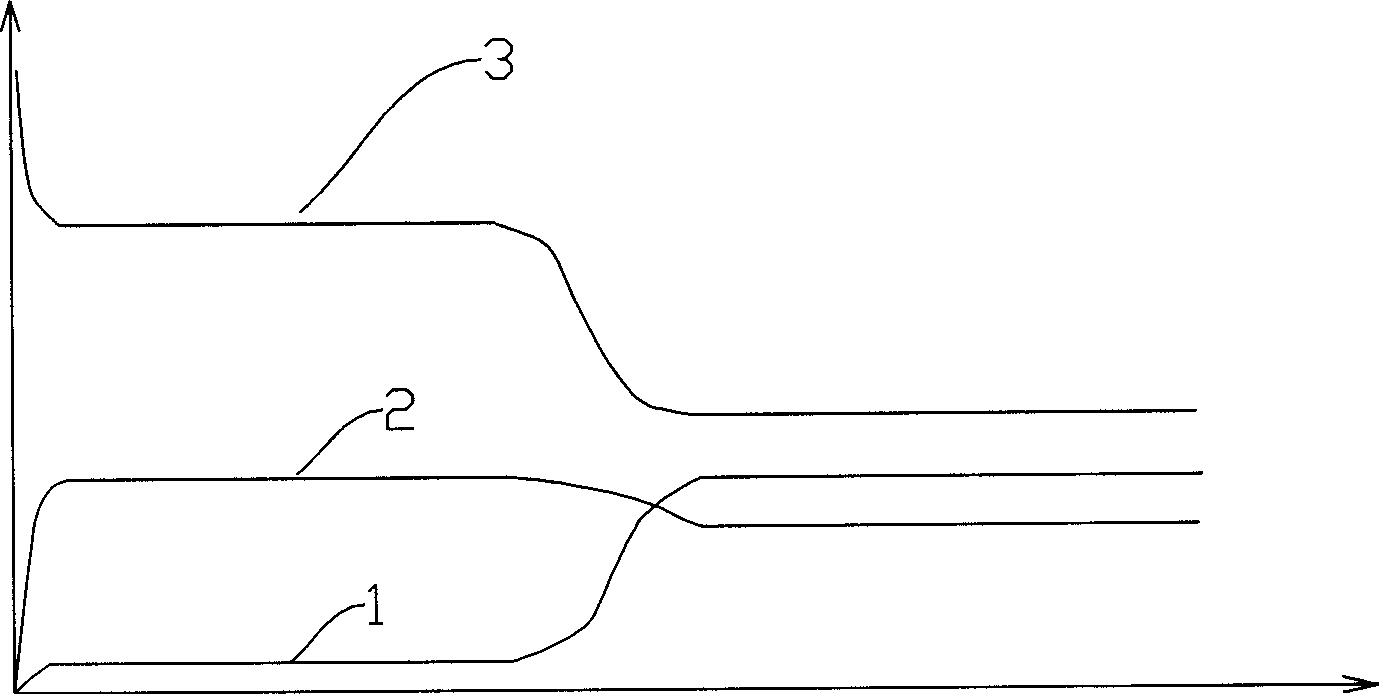

A technology for generating process and silicon devices, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve the problems of poor particle penetration resistance, affecting reliability, and high defect density at the interface. Achieve excellent optoelectronic properties, reduce soft breakdown and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

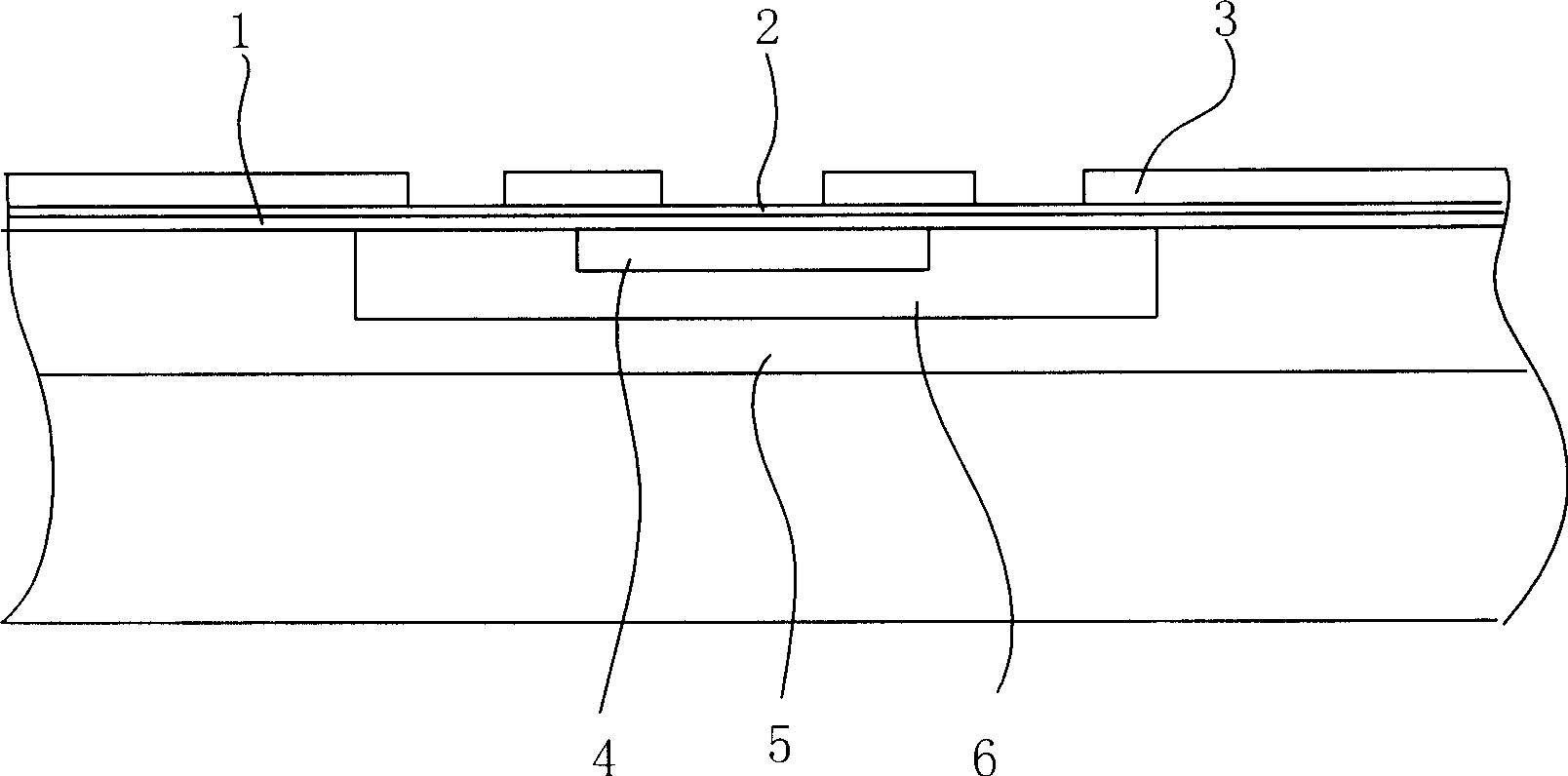

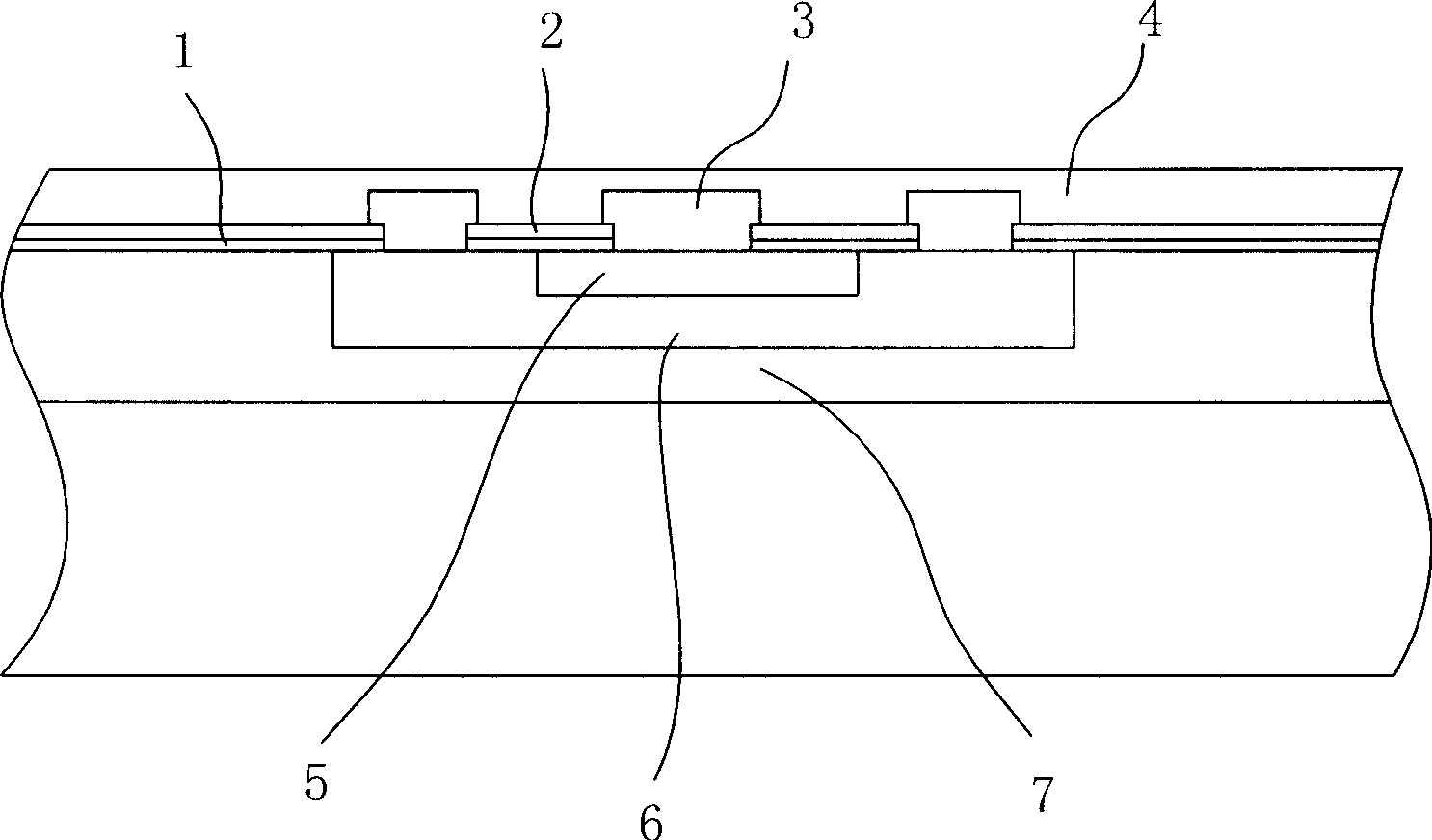

[0024] An oxygen-rich SiOxNy (silicon oxynitride) film layer is formed on the silicon substrate with nodes, and the film thickness is 2000 angstroms. The oxygen-enriched SiOxNy film is formed by low-pressure chemical vapor deposition. It is formed in a low-pressure environment of 280 mTorr and a temperature of 620 degrees Celsius, and a certain ratio of N 2 O and SiH 4 generate. Its atomic content ratio is: Si:O:N=75:20:5. The oxygen-rich SiOxNy film has a stress similar to that of the silicon substrate, which greatly reduces the number of defects at the interface; and its high density makes it have a strong ability to block particle penetration, which limits the charge at the interface. increase in particles. The above two points jointly ensure the stability of the state of the device interface.

[0025] After the lower oxygen-enriched SiOxNy film is formed, a certain amount of N 2 O, SiH 4 and NH3 to re-grow a nitrogen-enriched SiOxNy film layer whose stress is close ...

Embodiment 2

[0032]An oxygen-rich SiOxNy (silicon oxynitride) film layer is formed on the silicon substrate with nodes, and the film thickness is 3500 angstroms. The film is formed by low-pressure chemical vapor deposition. It is formed by feeding a certain ratio of N2O and SiH4 in a low-pressure environment of 310 millitorr and a temperature of 645 degrees Celsius. Its atomic content percentage is: Si:O:N=65:30:5. The film has a stress similar to that of the silicon substrate, which greatly reduces the number of defects at the interface; and its high density makes it have a strong ability to block particle penetration, which limits the increase of charged particles at the interface. The above two points jointly ensure the stability of the state of the device interface.

[0033] After the upper film of the composite film is formed, the process conditions are changed in the same deposition furnace, that is, the temperature is raised to 770 degrees Celsius, and a certain amount of N2O, SiH...

Embodiment 3

[0037] An oxygen-rich SiOxNy (silicon oxynitride) film layer is formed on the silicon substrate with nodes, and the film thickness is 5000 angstroms. The film is formed by low-pressure chemical vapor deposition. It is formed by feeding a certain ratio of N2O and SiH4 in a low-pressure environment of 340 millitorr and a temperature of 670 degrees Celsius. Its atomic content percentage is: Si:O:N=55:40:5. The film has a stress similar to that of the silicon substrate, which greatly reduces the number of defects at the interface; and its high density makes it have a strong ability to block particle penetration, which limits the increase of charged particles at the interface. The above two points jointly ensure the stability of the state of the device interface.

[0038] After the upper film of the composite film is formed, the process conditions are changed in the same deposition furnace, that is, the temperature is raised to 800 degrees Celsius, and a certain amount of N2O, Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com