Tissue repair material in polycomponent amino acid polymers and preparation method thereof

A tissue repair and amino acid technology, applied in medical science, prosthesis, etc., can solve the problems of loss of physiological activity, good softness, poor rigidity, etc., to overcome insufficient mechanical properties, high safety, good biological activity and compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

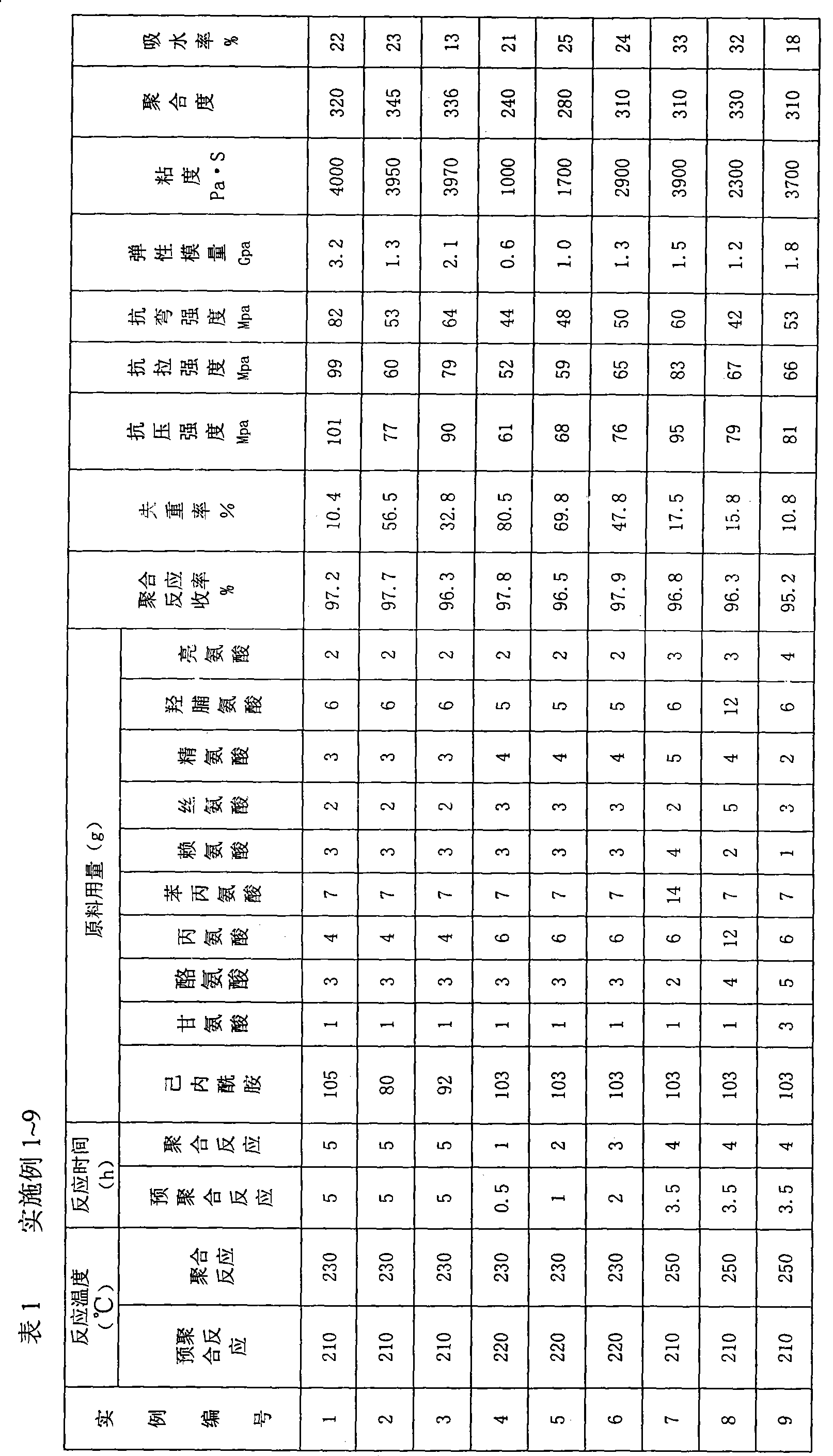

[0017] The amount of caprolactam and other amino acids is shown in Table 1. Add it to a 250ml three-neck bottle, and under the protection of nitrogen, stir and slowly heat up to 80°C-200°C. ~250°C for polymerization. The reaction times are shown in Table 1. After cooling to room temperature, an orange-yellow product was obtained with a yield greater than 95%. The mechanical properties, weight loss rate, degree of polymerization and viscosity of the obtained degradable polymer are also shown in Table 1.

Embodiment 10

[0019] Add 90g of caprolactam, 1g of glycine, 6g of alanine, 7g of phenylalanine, 2g of lysine, and 6g of hydroxyproline into a 250ml three-necked bottle. Under stirring, the temperature was raised slowly to 200°C and melted. Raise the temperature to 220°C for 3 hours, then raise the temperature to 230°C for 3.5 hours, and cool to room temperature to obtain an orange-yellow product with a yield of 96%; the melting point is 175°C, and the resulting degradable polymer has a compressive strength of 90Mpa and a tensile strength of 83Mpa, flexural strength 65Mpa, elastic modulus 2.6Gpa; its degree of polymerization is 310, viscosity at 220°C is 3100Pa·S; after soaking in simulated body fluid for 12w, the weight loss is 32%.

Embodiment 11

[0021]Add 85g of caprolactam, 1g of glycine, 4g of alanine, 6g of phenylalanine, 2g of lysine, 6g of hydroxyproline, and 2g of tyrosine into a 250ml three-necked bottle. , under the protection of nitrogen, stirring slowly heated to 200 ° C, melting. Raise the temperature to 220°C for 3 hours, then raise the temperature to 230°C for 3 hours, and cool to room temperature to obtain an orange-yellow product with a yield of 97%; the melting point is 171°C, and the obtained degradable polymer has a compressive strength of 91Mpa and a tensile strength of 85Mpa, flexural strength 62Mpa, elastic modulus 2.2Gpa; its degree of polymerization is 300, viscosity at 220°C is 3000Pa·S; after soaking in simulated body fluid for 12w, the weight loss is 21%.

[0022] Example 11

[0023] Caprolactam 90g, glycine 1g, alanine 3g, phenylalanine 7g, lysine 2g, hydroxyproline 6g, tyrosine 3g, serine 5g, leucine 1.31g were added to a 250ml three-necked bottle, and Under the protection of nitrogen, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com