Method for producing portland cement clinker using domestic waste incineration residue

A technology of domestic waste incineration and Portland cement, which is applied in cement production and other directions, can solve the problems of not considering the hazards of durability, lack of pozzolanic activity, and increased treatment costs, so as to increase treatment costs, solve land tension and environmental problems. Pollution problem, the effect of alleviating the tension of land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

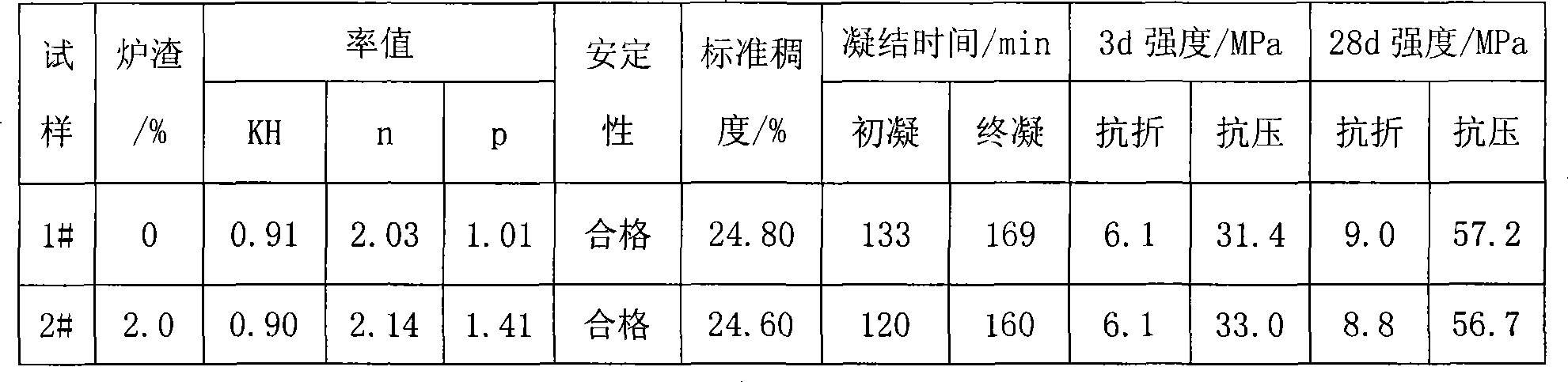

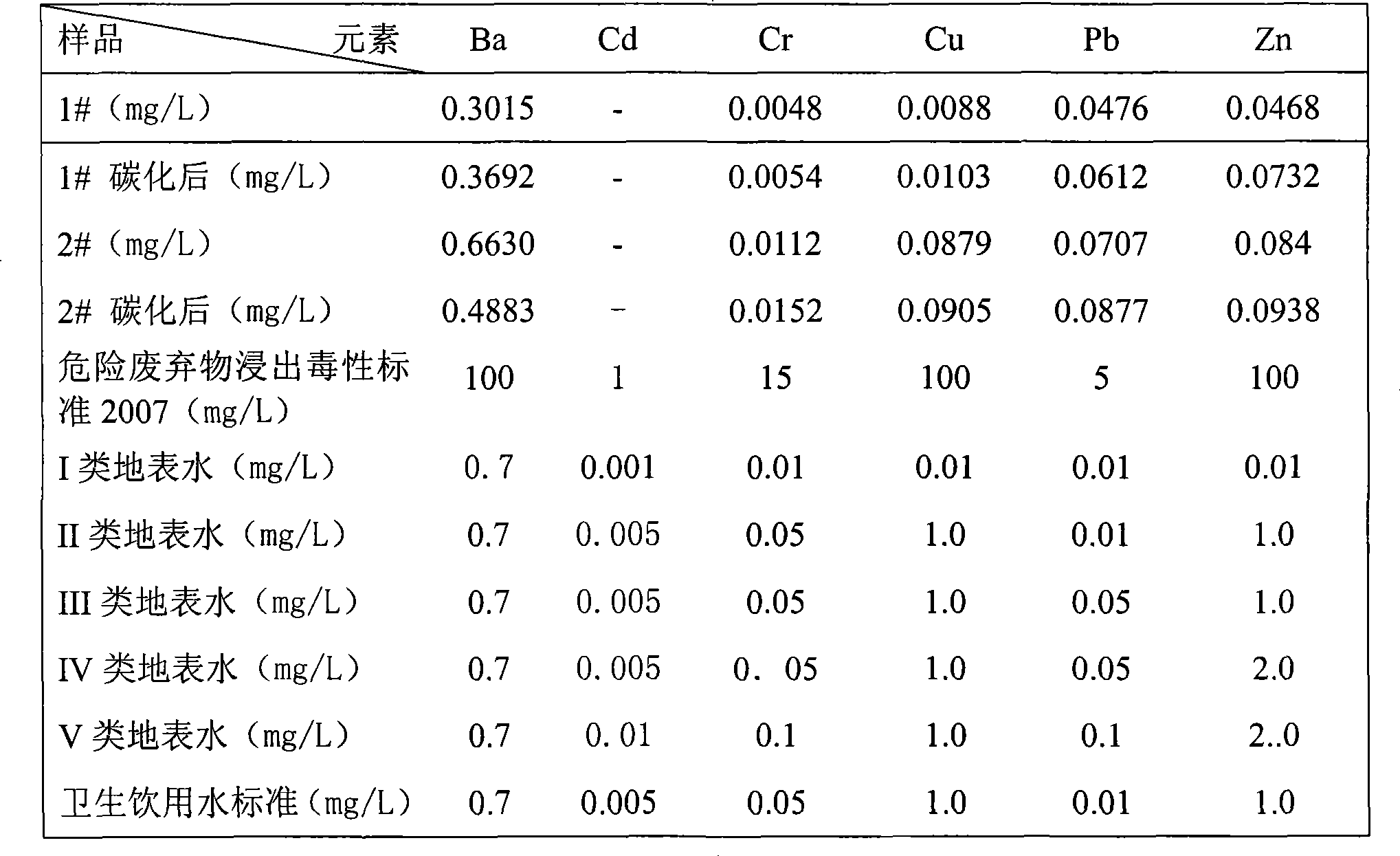

Embodiment 1

[0024] Co-processing the slag of the Likeng waste incineration power plant on a new type of dry-process cement kiln with a double series (kiln train and furnace train) five-stage suspension preheater and FLS spray-type calciner with a diameter of 4.75×75 meters Test. The cement kiln's decomposition furnace, 5-stage cylinder, kiln tail smoke chamber and smoke chamber rising flue are all designed with dust removal holes, air cannons and manual dust removal operation platforms. A bypass air release device is added at the position of the rising flue at the kiln tail close to the 5-stage tube (temperature range of 850 to 950℃), which is connected to the rising flue at the kiln tail through a controllable valve, and is equipped with a coarse powder classification cyclone. And bag filter and exhaust fan. Open the valve to make part of the materials and gas in the kiln enter the bypass system. The materials and the gas are separated by the coarse powder classification cyclone, and the mat...

Embodiment 2

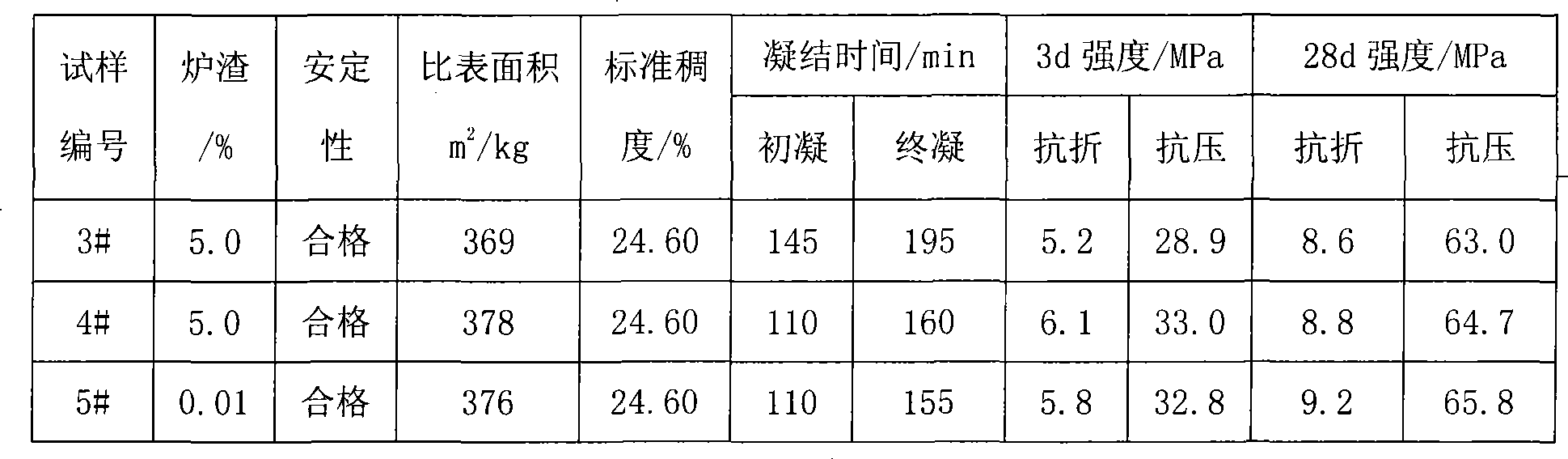

[0035] Through a Φ4.8×72m, a new dry process kiln production line with a double series of five-stage suspension preheater and an RSP calciner to co-dispose of the slag of the Likeng waste incineration power plant. This production line is additionally equipped with a bypass air release device at the outlet of the 5-stage cylinder. In terms of weight percentages, 5.0% of slag, 15.0% of pozzolan, 4.2% of high-iron clay, and 75.8% of limestone are used for white raw meal batching. The slag transported from the waste incineration power plant does not need to be separated, dried and deodorized. It enters the pre-homogenized siliceous material storage yard after weighing through the batching scale, and is stacked on the bottom. The clay material (both It can have a homogenizing effect, and can also prevent and reduce the escape of odor through the covering of the clay layer). According to the raw meal ratio, various materials are measured and transported to the raw meal mill by the iron ...

Embodiment 3

[0045] A test of co-processing slag from a domestic waste incineration power plant was carried out on a Φ4.0×60m, a new dry kiln production line with a single-series five-stage suspension preheater and a CDCR type calciner. In order to ensure the smooth progress of the test, a bypass venting device was added at the ascending pipeline from the outlet of the fifth-stage cylinder to the fourth-stage cylinder of the production line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com