Method for preparing poly(acrylic acid-acrylic amide)/hydrotalcite high water absorption resin

A technology of superabsorbent resin and acrylamide is applied in the field of preparation of poly/hydrotalcite nanocomposite superabsorbent resin by using hydrotalcite. The effect of salt properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] First, add hydrotalcite and modifier into N,N'-dimethylacetamide, stir vigorously at 70-80°C for 22-24 hours, filter with suction, wash and dry to obtain organically modified hydrotalcite , the modifier can be sodium methacrylate, sodium propene sulfonate or sodium dodecylsulfonate.

[0016] Add 150 g of cyclohexane and 0.99 g of dispersant Span-60 into a four-port glass jacketed reactor, and stir at room temperature. 22.5 grams of acrylic acid was placed in a beaker, and neutralized with 23.4 grams of 40% sodium hydroxide aqueous solution at 0°C. Add 2.25 g of acrylamide and 0.25 g of organically modified hydrotalcite (1 wt%) into the neutralized acrylic acid aqueous solution and stir evenly to prepare an emulsion. Finally, 0.045 grams of potassium persulfate and 0.0045 grams of N, N'-methylenebisacrylamide were added to the above-mentioned emulsion, stirred evenly, and placed in a reaction kettle. Under the protection of nitrogen, first react at 50°C for 1h, then re...

Embodiment 2

[0022] Same as Example 1, except that 0.5 gram of organically modified hydrotalcite (2wt%) was added to obtain the water absorption of granular poly(acrylic acid-acrylamide) / hydrotalcite nano superabsorbent resin ≥ 736.7g / g, Salt tolerance ≥121.3g / g.

Embodiment 3

[0024] Same as Embodiment 1, the difference is that 0.74 gram of organically modified hydrotalcite (3wt%) is added to obtain granular poly(acrylic acid-acrylamide) / hydrotalcite nano superabsorbent resin with water absorption ≥ 1106g / g, resistant to Salt rate ≥ 145.3g / g.

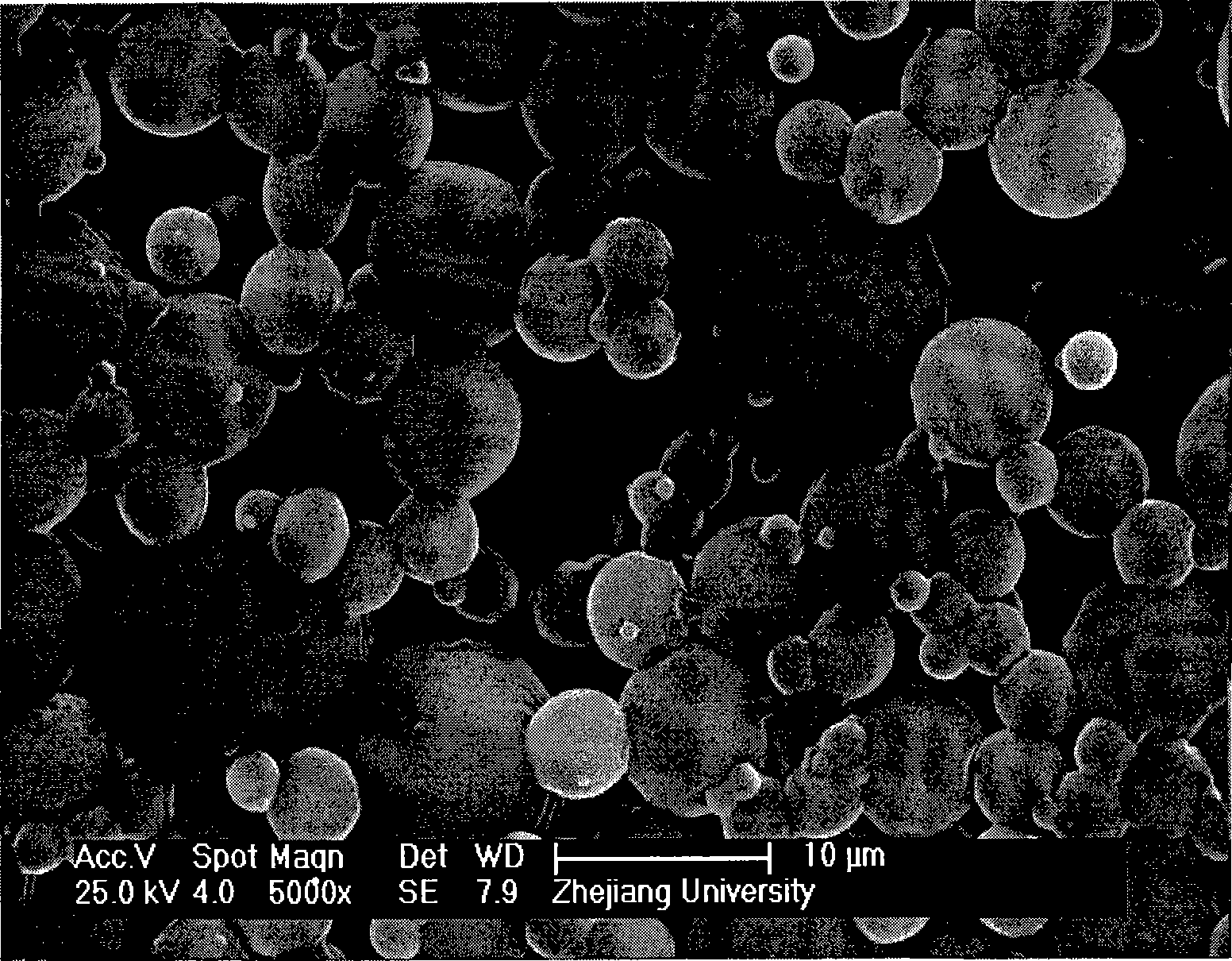

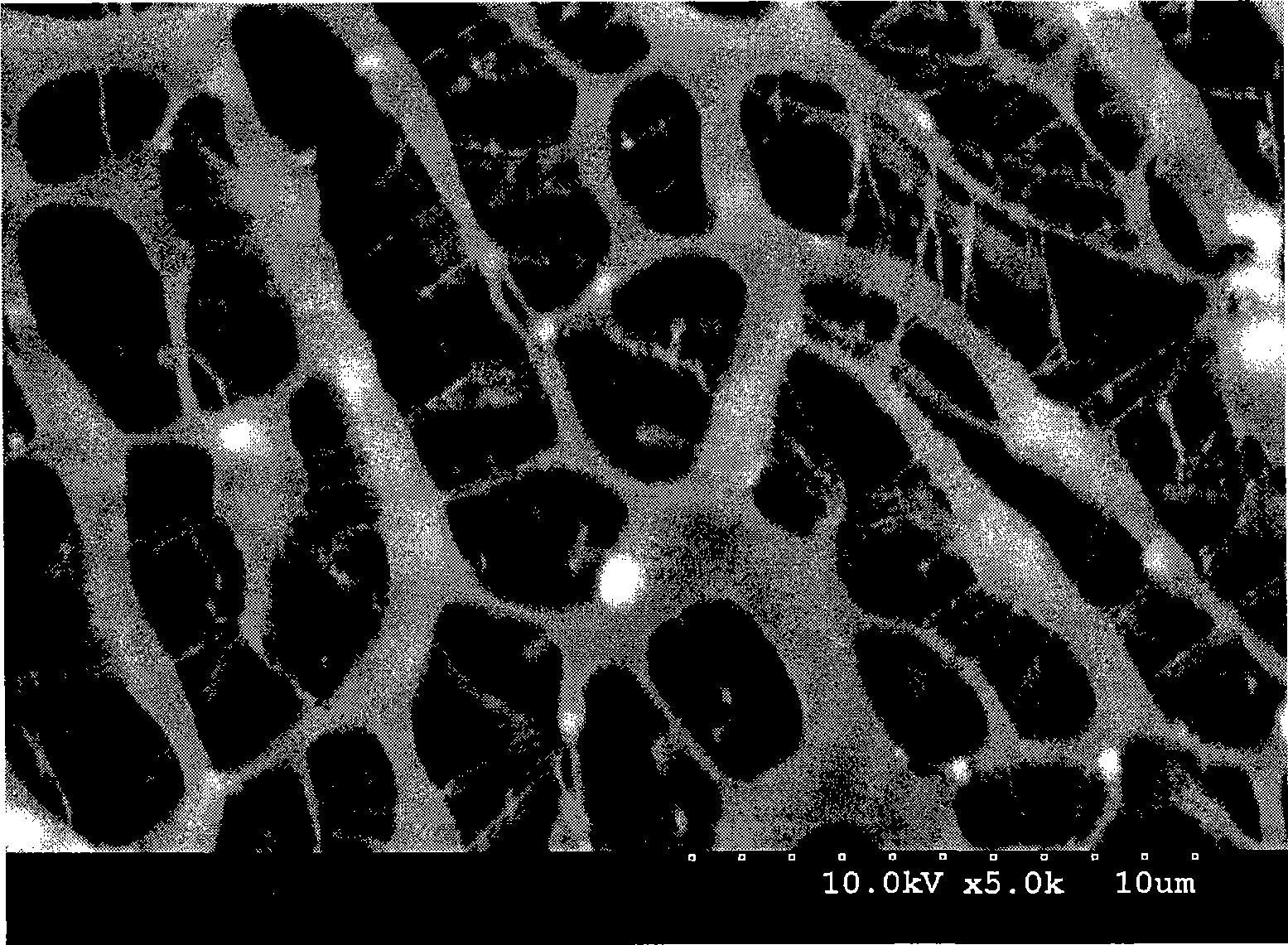

[0025] like figure 1 As shown, use the SIRION-100 scanning electron microscope (FEI, USA) to observe the particle morphology characteristics of the material; as figure 2 As shown, in order to observe its porous network structure, the resin was fully swollen, freeze-dried and used for structural characterization (SEM, Hitachi, S-3000N; Gatan, Alto-2100), and the sample must be gold-plated before testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com