Enzymology method for preparing polysaccharide bioflocculant

A biological flocculant and polysaccharide technology, applied in the direction of flocculation/sedimentation water/sewage treatment, fermentation, etc., to achieve excellent quality and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation of dextran sucrase, including the selection and cultivation of enzyme-producing bacteria, enzyme production, separation and purification, is a relatively complicated and specialized process. For the detailed process, please refer to the Chinese patent "A Syrup Containing Isomaltooligosaccharides and Fructose and Its Preparation Method" (ZL 03100280.3).

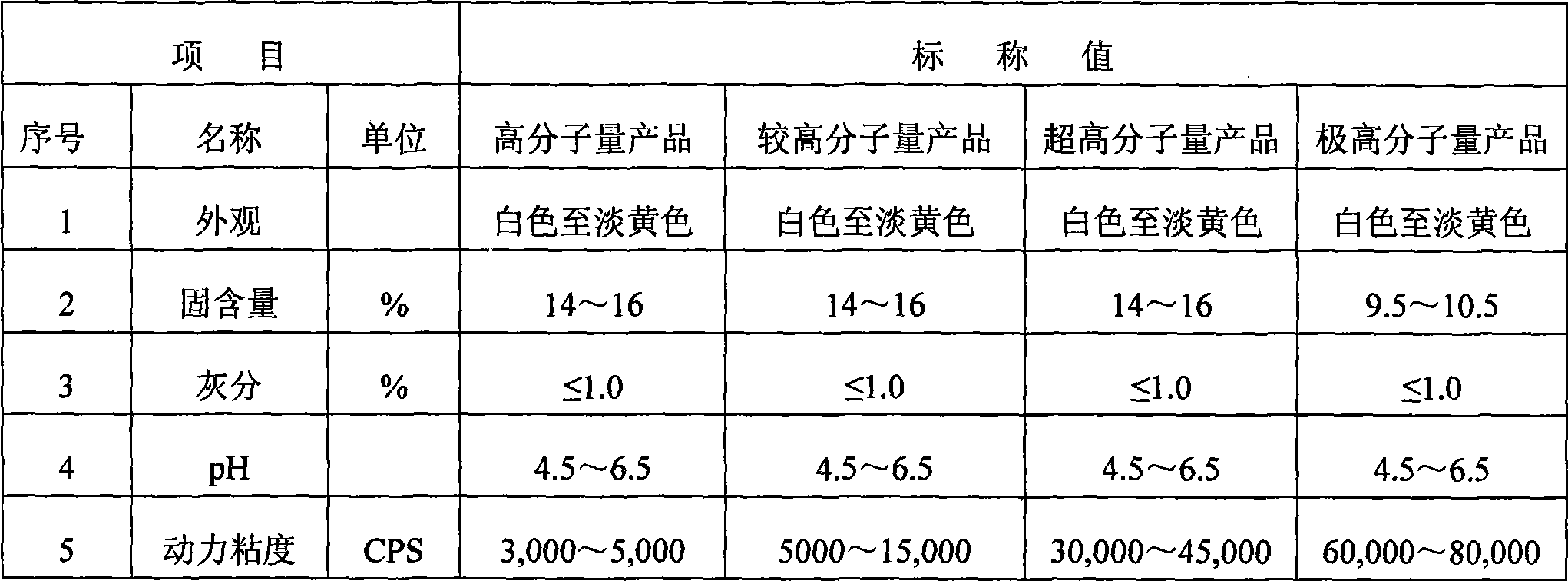

[0024] Polysaccharide bioflocculants with different molecular weights can be prepared by changing the substrate concentration, enzyme concentration and reaction conditions. According to the special requirements put forward by several largest water treatment companies in the world, the dynamic viscosity at 25°C is as follows:

[0025] A. High molecular weight: 3000~5000CPS (15% concentration)

[0026] B. Higher molecular weight: 5000~15000CPS (15% concentration)

[0027] C. Ultra-high molecular weight: 30000~45000CPS (15% concentration)

[0028] D. Extremely high molecular weight: 60000~80000CPS (10% c...

Embodiment 1

[0069] Take a clean 2000 ml beaker or a three-neck flask, add 274 grams of high-quality sucrose, then add an appropriate amount of distilled water, stir to dissolve, and adjust the volume to 1000 ml, further add 10 ml of 0.5% calcium chloride solution, stir and mix; Then adjust the pH to 5.2-5.4 with 30% acetic acid buffer. After the above solution was boiled for 15 minutes, it was cooled to 25°C.

[0070] Add 800 IU (ie 17.5 ml) of freshly prepared enzyme solution (the enzyme activity of this batch is 456 IU / ml) and mix well, then adjust the pH to 5.2-5.4 with 10% acetic acid.

[0071] Put the above reactants in a constant temperature water bath at 20-22°C, turn on the stirrer, adjust the stirring speed to 30-40 rpm, and start timing, and then operate in the manner of stirring for 1 hour and stopping for 2 hours, during which the temperature should be Maintain constant and keep the operating environment clean to avoid bacterial contamination.

[0072] After the reaction has...

Embodiment 2

[0076] Take a clean 10-liter glass or stainless steel container, add 1.25 kg of high-quality sucrose, add 3 liters of distilled water, stir to dissolve, then add distilled water to make the solution volume 5 liters, stir and mix well, then add 50 ml of 0.5% calcium chloride solution, stir Mix well, then adjust the pH to 5.2-5.4 with 30% acetic acid buffer, heat and boil for 15 minutes, then cool to room temperature.

[0077] Put the above solution in a constant temperature water bath at 22-24°C and stir for about half an hour. When the internal temperature of the solution is constant within the above range, add 50,000 IU (i.e. 109.6 ml) of enzyme solution (the activity is the same as in Example 1), stir and mix well, and use Adjust the pH to 5.2-5.4 with 10% acetic acid, continue to stir, and adjust the speed to 40-60 rpm. After stirring for 1 hour, stop for half an hour until the viscosity reaches 5,000-15,000, then heat to terminate the reaction. The separation, purification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com