Method for preparing diglyceride through continuous glycerolysis by enzyme method

A diglyceride and glycerol hydrolysis technology, which is applied in the field of enzymatic continuous preparation of diglyceride, can solve the problems of large solvent usage, reduced enzyme activity, and difficulty in separation, so as to improve catalytic effect, prolong service life, and improve interaction solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

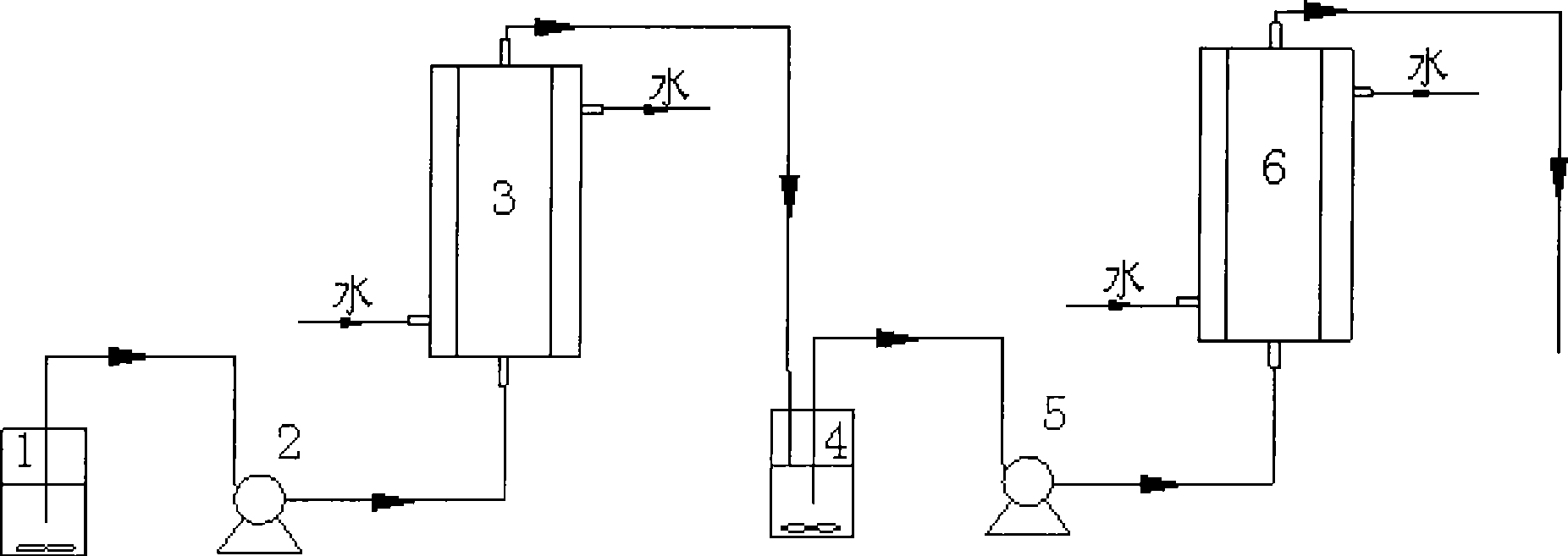

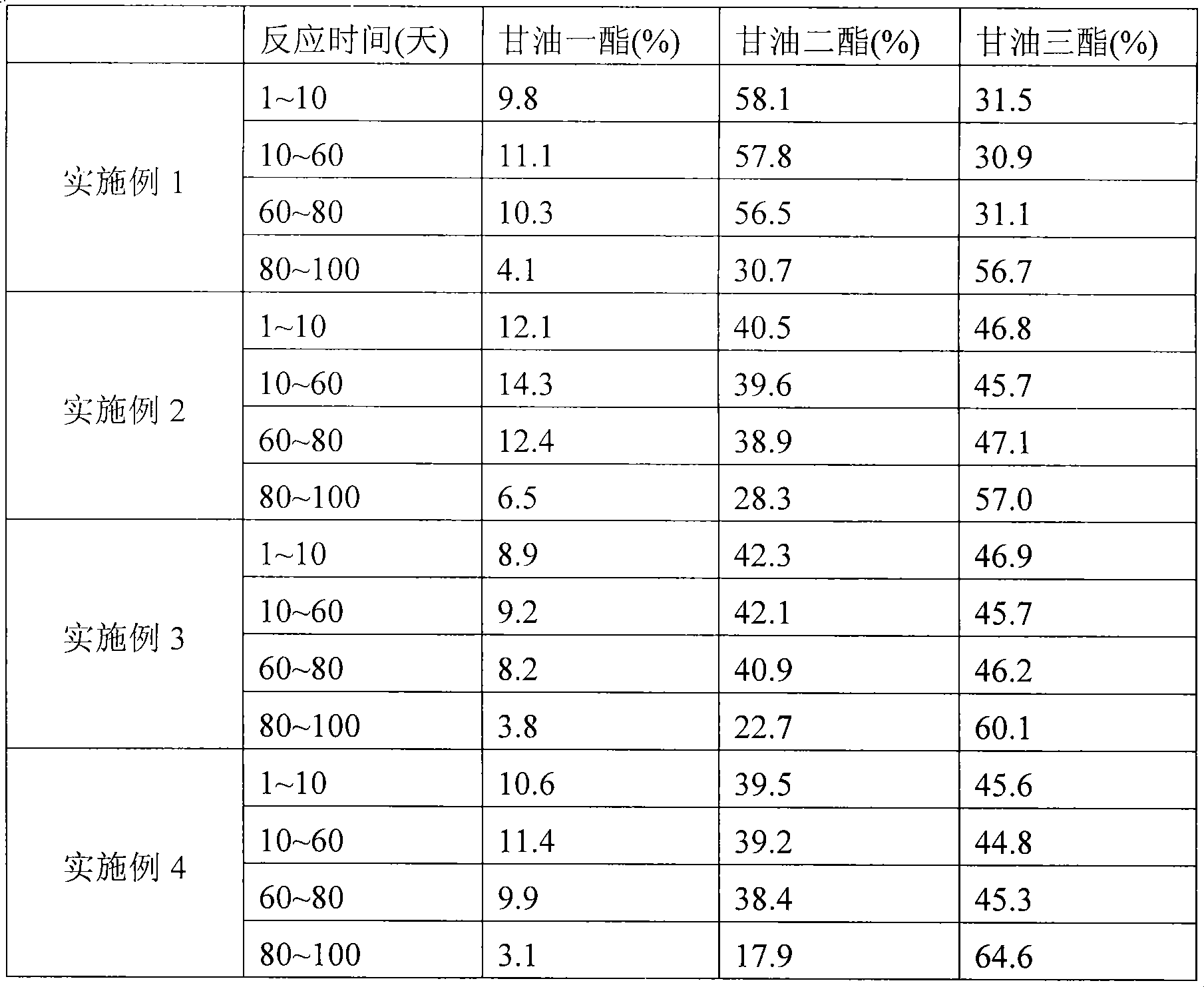

[0023] Put 100g of soybean oil and 20g of glycerin into the conical flask, then add 15mL of n-hexane, connect the condensing device, carry out magnetic stirring, and mix evenly, as figure 1 As shown, the reactant passed through two packed column reactors (10 cm in length, 1.5 cm in inner diameter, 3 cm in outer diameter, 55° C., with a condenser on top of the column) equipped with Novozyme 435 immobilized lipase at a flow rate of 0.5 mL / min. During the reaction process, the reactants (soybean oil, glycerin and n-hexane) were replenished in good time so as to conform to the ratio of raw materials and solvents in Table 1. Samples of different reaction times were collected respectively, and the organic solvent was removed by vacuum distillation (0.1Mpa, 70°C). , to obtain the product, analyzed by HPLC, the results are shown in Table 2.

Embodiment 2

[0025] 100g rapeseed oil and 15g glycerol were added into the Erlenmeyer flask and mixed evenly, then 18mL No. 6 solvent was added, and magnetic stirring was carried out, and the reactant passed through two packed column reactors equipped with Novozyme 435 immobilized lipase at a flow rate of 0.5mL / min ( The length is 10cm, the inner diameter is 1.5cm, the outer diameter is 3cm, 60°C, the top of the column is equipped with a condenser). During the reaction, the reactants (rapeseed oil, glycerol and No. 6 solvent) were replenished in time to meet the ratio of raw materials and solvents in Table 1. All the other operations are the same as in Example 1. The results are shown in Table 2.

Embodiment 3

[0027] 100g of sunflower oil and 10g of glycerol were added into the Erlenmeyer flask and mixed evenly, then 15mL of pentane was added, and magnetically stirred, and the reactant passed through two packed column reactors (length 10cm) equipped with Novozyme 435 immobilized lipase at a flow rate of 1mL / min. , inner diameter 1.5cm, outer diameter 3cm, 50°C, column top with condenser). During the reaction, the reactants (sunflower oil, glycerol and pentane) were replenished in good time to meet the ratio of raw materials and solvents in Table 1. All the other operations are the same as in Example 1. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com