Method for concentrating waster solution from process for processing seafood

A technology of processing and waste liquid, applied in separation methods, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as high processing costs, inability to carry out large-scale production, and limited processing conditions, so as to reduce labor intensity, Achieve recycling and clean production, reduce the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

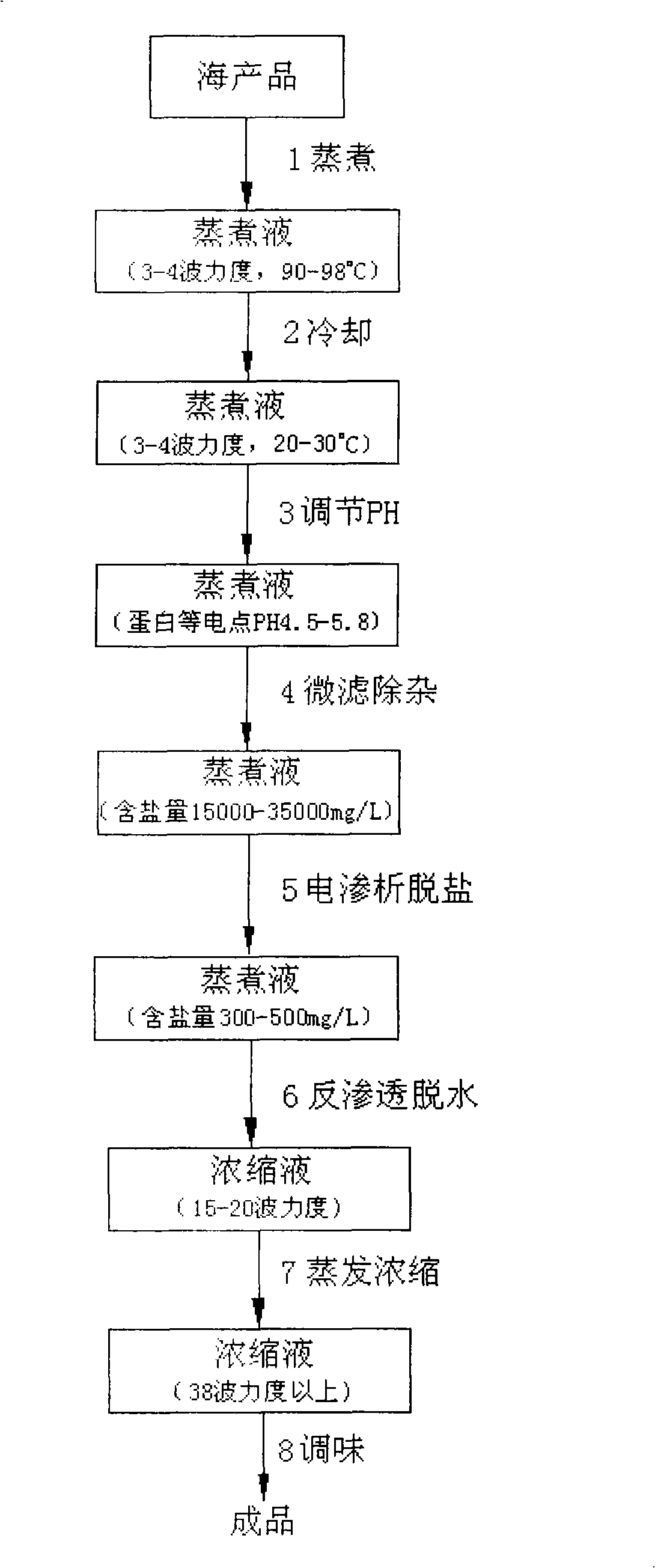

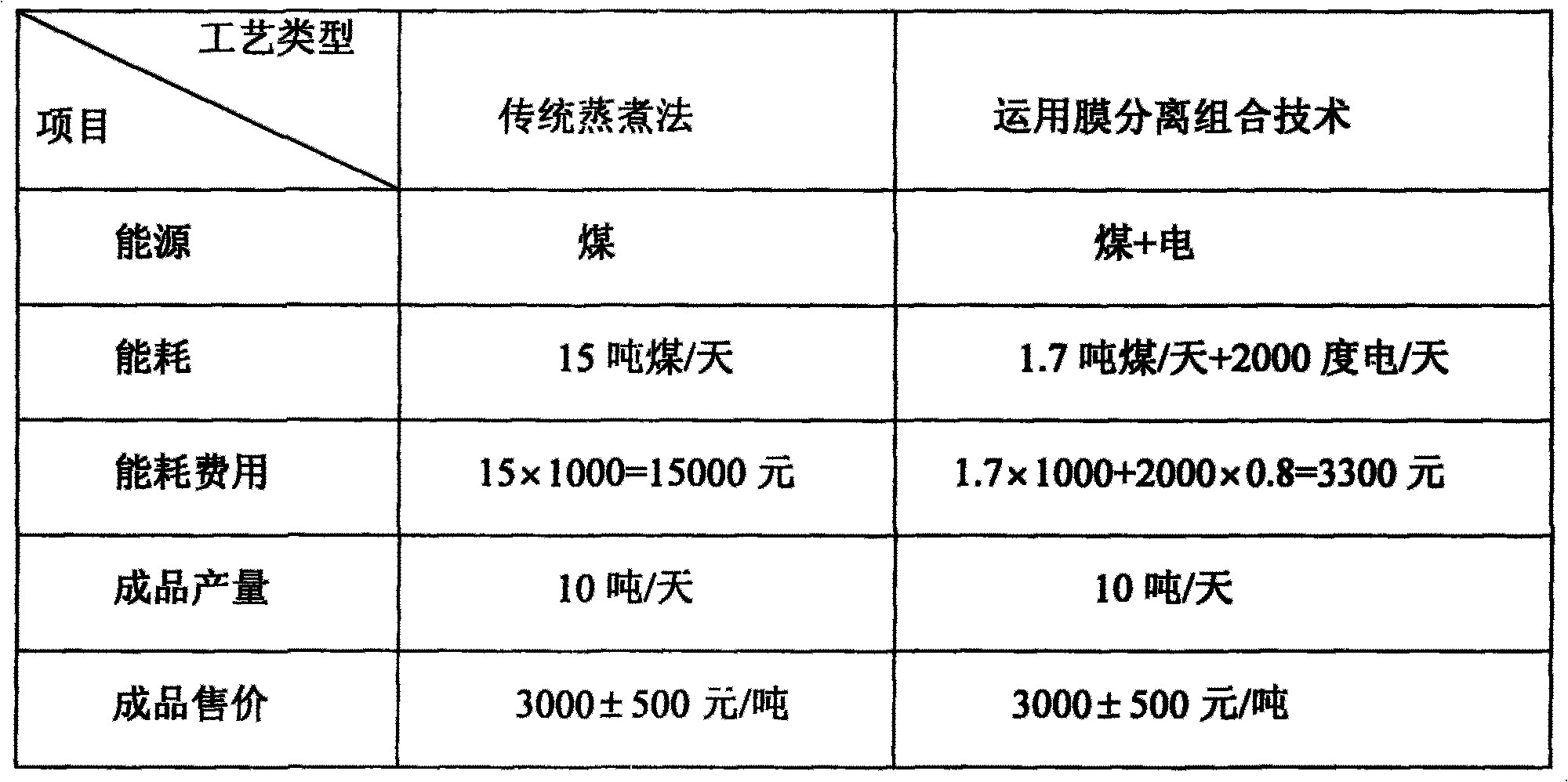

[0019] The invention provides a method for concentrating the waste liquid produced in the processing of seafood based on the combined membrane separation technology. It adopts the combined technology of membrane separation and at the same time sets a closed-circuit circulation process, which can significantly reduce energy consumption. Low power consumption, low operating cost and good treatment effect.

[0020] Refer to attached picture. It sequentially includes the following process steps:

[0021] 1) Cooling, using a circulating water cooling system or a seawater direct-flow cooling water system for the cooking waste liquid of seafood to cool the cooking liquid at 90-98°C to 20-30°C.

[0022] 2) Adjust the pH value: adjust the pH value to the isoelectric point of seafood protein (pH4.5-5.8).

[0023] 3) Microfiltration membrane separation and impurity removal: pump into the microfiltration membrane separation process to remove impurities such as colloids, organic matter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com