Polypropylene/polystyrene alloy and method of producing the same

A polystyrene and polypropylene technology, applied in the field of polypropylene/polystyrene alloy and its preparation, can solve the problems of poor printability, low hardness, low shrinkage rate, etc., and achieve good comprehensive mechanical properties, high surface gloss, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

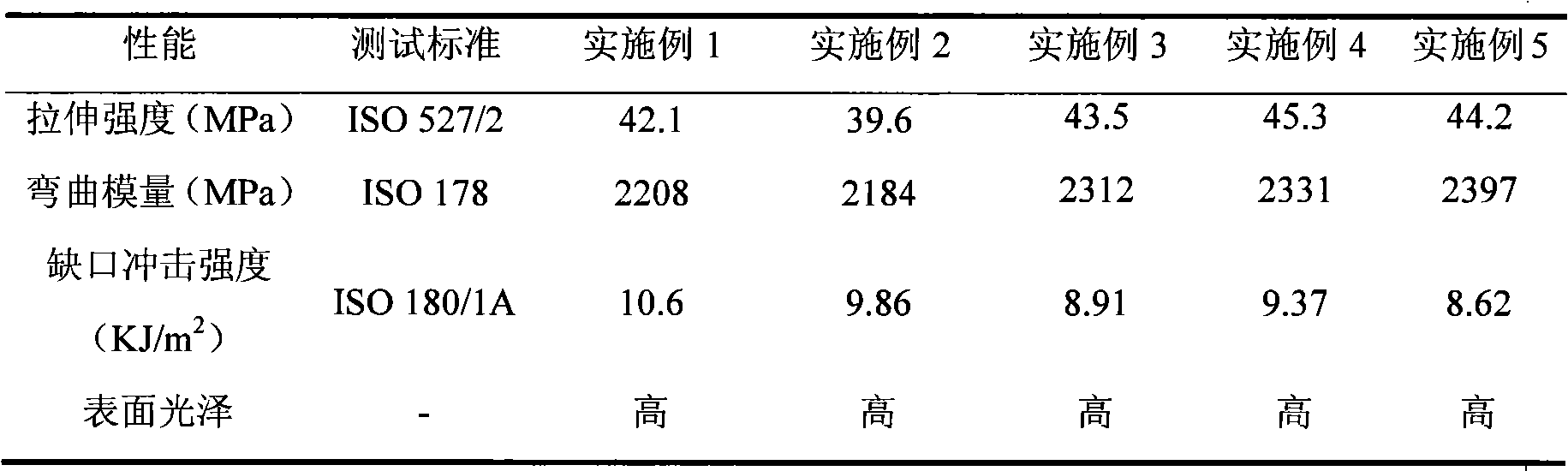

Examples

Embodiment 1

[0026] A polypropylene / polystyrene alloy, consisting of the following raw materials in parts by weight: 40 parts of polypropylene (brand name: PP-PT231 manufacturer: Formosa Plastics Group); 60 parts of polystyrene; 5 parts of modifier; 0.4 parts of nucleating agent; 5 parts of filler; 0.5 parts of antioxidant; 2.5 parts of processing aid.

[0027] The tensile strength of the polypropylene is 35MPa, and the flexural modulus is 1300MPa. The trade mark of described polystyrene is PS GPPS 251P (Shanghai Secco Petrochemical Co., Ltd.). The modifier is composed of 2 parts of maleic anhydride grafted polypropylene and 3 parts of hydrogenated block polymer. The hydrogenated block polymer is a styrene-isoprene-styrene block copolymer. The nucleating agent is NA-11 (Ciba Specialty Chemical Co., Ltd.). The filler is organic bentonite. Described antioxidant is antioxidant 168 (Swiss Ciba Company). Described processing aid is white mineral oil.

[0028] The preparation method of the...

Embodiment 2

[0030] A polypropylene / polystyrene alloy, consisting of the following raw materials in parts by weight: 40 parts of polypropylene (brand: PP-J700 manufacturer: Langang Petrochemical); 60 parts of polystyrene; 40 parts of modifier; 1.2 parts of nucleating agent; 30 parts of filler; 1.5 parts of antioxidant; 10 parts of processing aid.

[0031] The tensile strength of the polypropylene is 30MPa, and the flexural modulus is 1100MPa. The trade mark of described polystyrene is PS GPPS 251P (Shanghai Secco Petrochemical Co., Ltd.). The modifier consists of 10 parts of chlorinated polyethylene, 10 parts of ethylene-n-butyl acrylate-glycidyl methacrylate copolymer, 10 parts of linear low density polyethylene grafted with maleic anhydride and ethylene-acetic acid 10 parts of vinyl ester copolymer. The nucleating agent is Microstat 42 (Shanghai Shengxingxing Chemical Co., Ltd.). The filler is composed of 10 parts of modified calcium carbonate and 20 parts of glass microspheres. Desc...

Embodiment 3

[0034] A polypropylene / polystyrene alloy, consisting of the following raw materials in parts by weight: 40 parts of polypropylene (brand: PP-HP748L manufacturer: Taiwan FORMOSA company); 60 parts of polystyrene; 20 parts of modifier; 0.8 parts of nucleating agent; 20 parts of filler; 1 part of antioxidant; 5.5 parts of processing aid.

[0035] The tensile strength of the polypropylene is 40MPa, and the flexural modulus is 1200MPa. The trade mark of described polystyrene is PS GPPS 251P (Shanghai Secco Petrochemical Co., Ltd.). The modifier is composed of 10 parts of maleic anhydride grafted polypropylene and 10 parts of hydrogenated block polymer. The hydrogenated block polymer consists of 3 parts of styrene-ethylene-propylene-styrene type block copolymer, 3 parts of styrene-ethylene-butylene-styrene type block copolymer and styrene-ethylene- 4 parts of butene block copolymer. The nucleating agent is modified talcum powder. The filler consists of 10 parts of organic benton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com