Method for producing capillary electrochromatography monolithic column made from silicon dioxide-titanic oxide integral material and uses thereof

A technology of titanium dioxide and silicon dioxide, which is applied in the field of preparation of electrochromatographic monolithic columns, can solve problems such as powder agglomeration, performance index impact, and inappropriate filling of capillary electrochromatographic packed columns, and achieve good stability and repeatability and long service life Longer, less non-specific adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

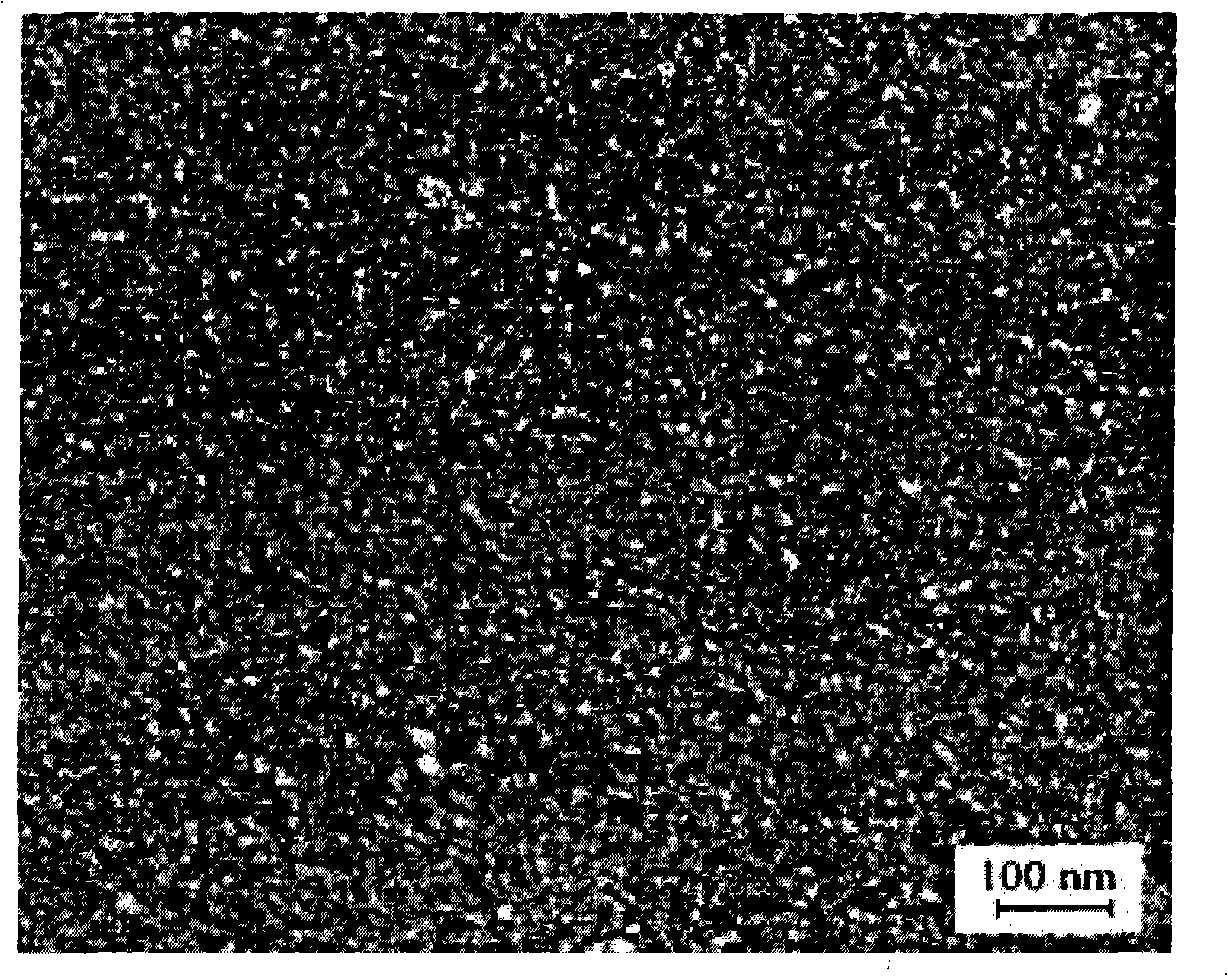

[0036] Preparation of monolithic column: mix 2.08g tetraethyl orthosilicate, 2.404g isopropanol, and 0.36g water, add hydrochloric acid dropwise to make the pH of the solution 2, stir for 1h; add titanium with a molar ratio of 1:1 dropwise Add 0.16 g of CTAB, heat at 40° C. for 3 hours, and age for 1 day. figure 1 For coated SiO 2 -TiO 2 SEM image of the overall material.

Embodiment 2

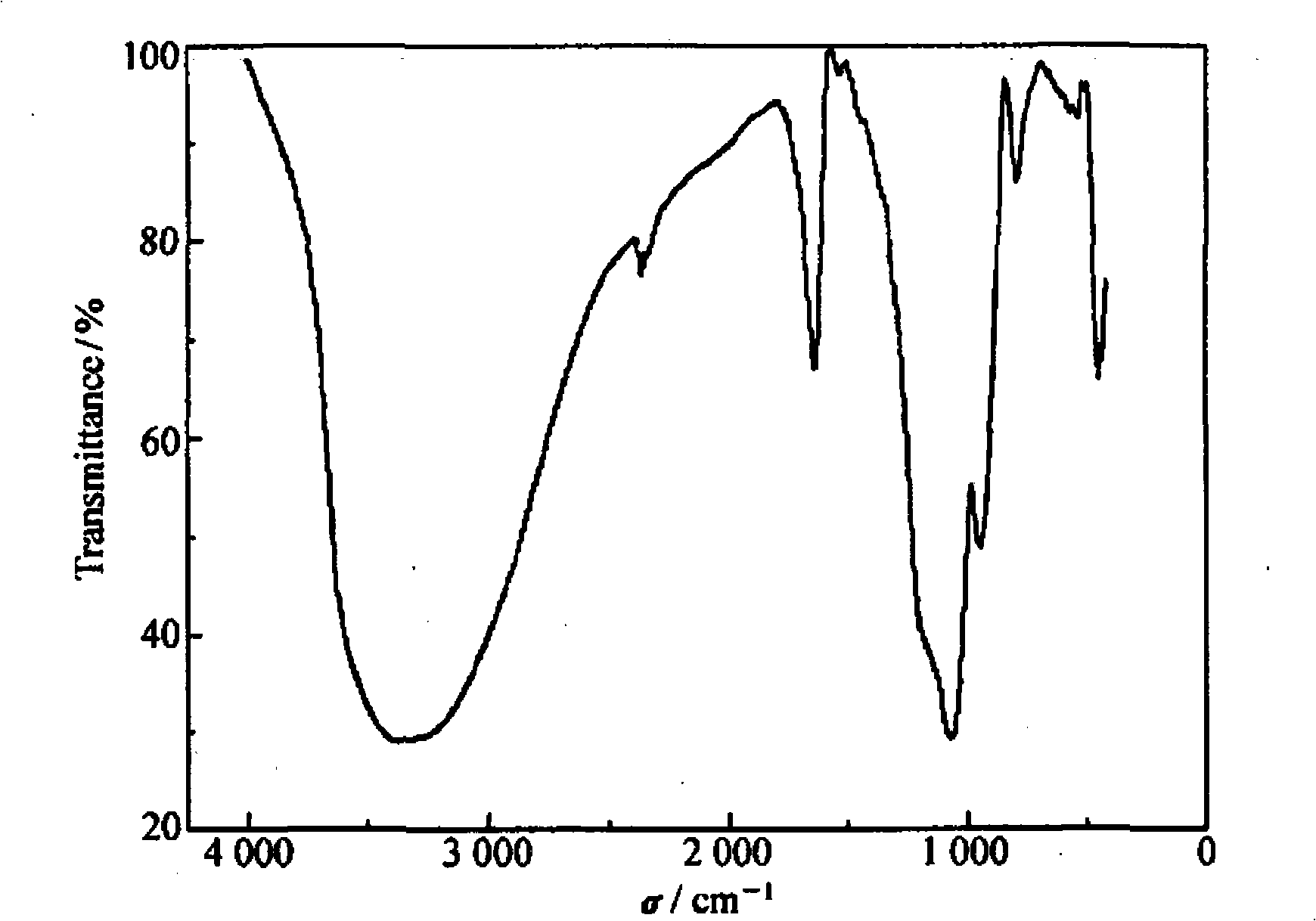

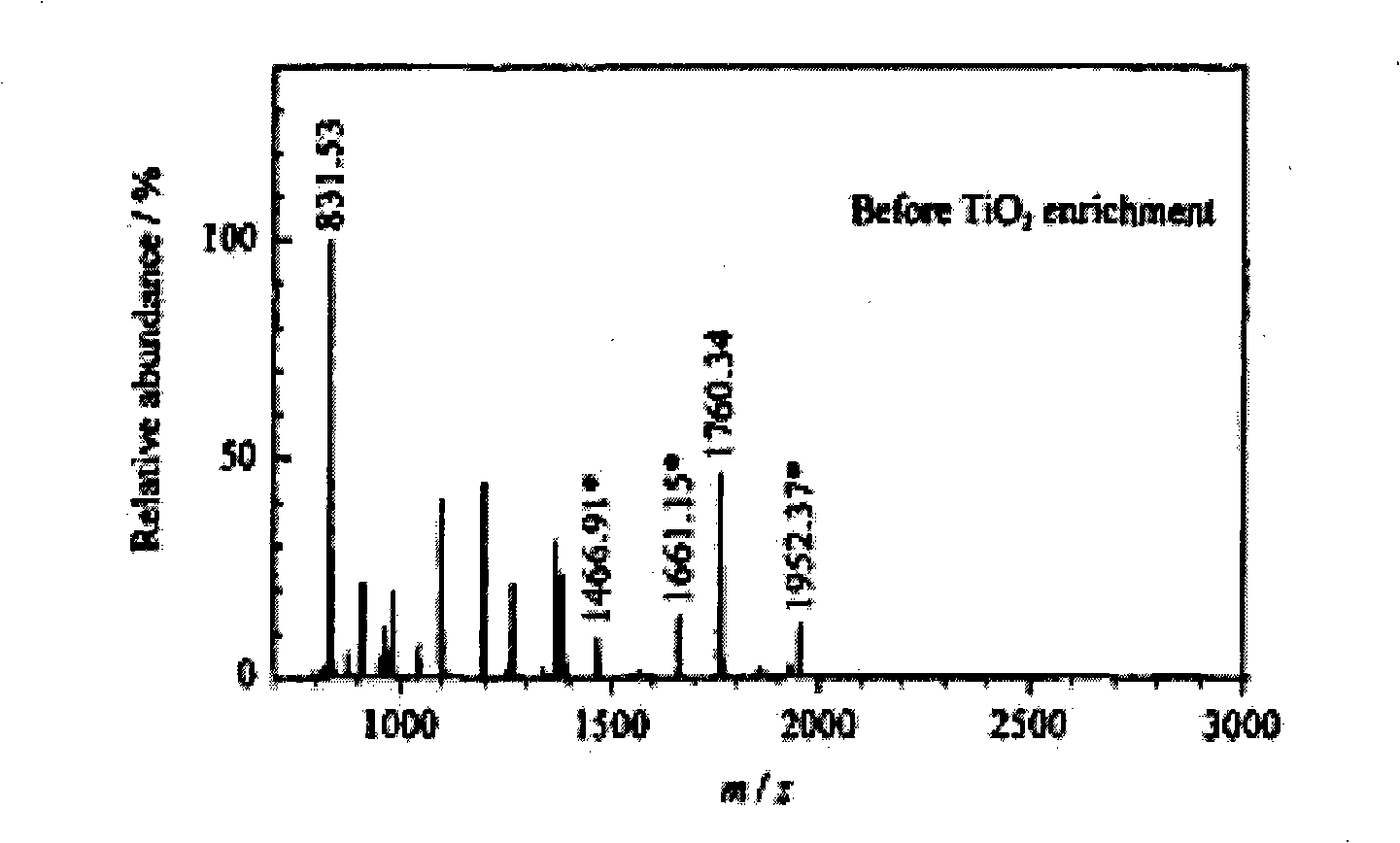

[0038] Preparation of monolithic column: mix 2.08g tetraethyl orthosilicate, 2.404g isopropanol, and 0.36g water, add hydrochloric acid dropwise to make the pH of the solution 2, stir for 1h; add titanium with a molar ratio of 1:1 dropwise Add 0.18 g of CTAB, heat at 30° C. for 5 hours, and age for 1 day. figure 2 Digested peptides of α-casein treated with SiO 2 -TiO 2 Mass spectra before and after monolithic column enrichment.

Embodiment 3

[0040]Preparation of monolithic column: mix 2.08g tetraethyl orthosilicate, 2.404g isopropanol, and 0.36g water, add hydrochloric acid dropwise to make the pH of the solution 2, stir for 1h; add titanium with a molar ratio of 1:1 dropwise A mixed solution of 4.47 g tetrabutyl acetylacetone and acetylacetone was stirred for 30 minutes; 0.2 g of CTAB was added, heated at 40° C. for 5 hours, and aged for 1 day. Figure 3a and Figure 3b Digested peptides of α-casein treated with SiO 2 -TiO 2 Mass spectra before and after monolithic column enrichment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com