Self-assembly modified titanium or titanium alloy material from layer to layer as well as preparation method and use thereof

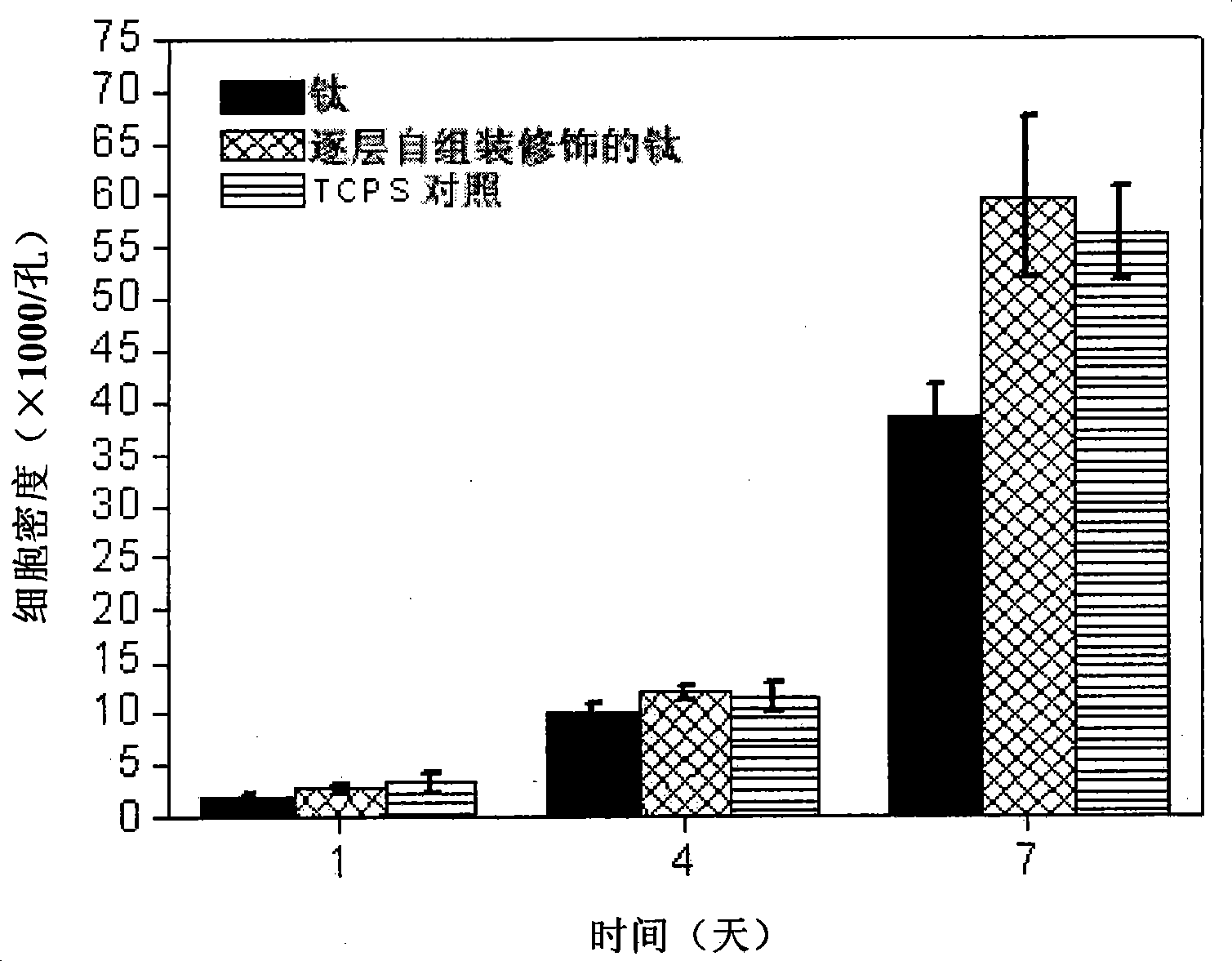

A layer-by-layer self-assembly, titanium alloy technology, applied in the preparation of titanium or titanium alloy materials, in the field of titanium or titanium alloy materials, to achieve good promotion and application value, mild preparation conditions, and good clinical application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

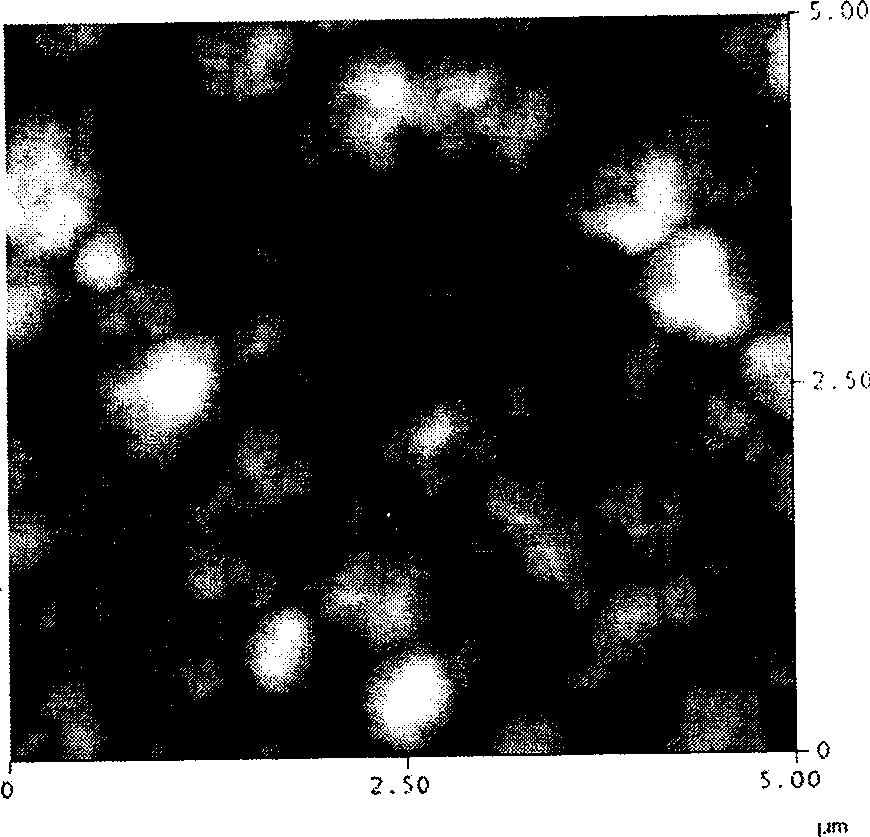

[0031] This embodiment is a layer-by-layer self-assembled modified titanium film, and its preparation method includes the following steps:

[0032] A, take by weighing chitosan 0.5g, adding concentration is 50mL of acetic acid solution of 10mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 1%;

[0033] b. Weigh 0.5 g of gelatin, add 25 mL of deionized water whose pH value is adjusted to 10 with sodium hydroxide, and dissolve at a temperature of 40° C. to prepare a gelatin solution with a concentration of 2% by mass;

[0034] C, put titanium film in the chitosan solution that step a makes, soak for 10 minutes, take out;

[0035] d. Washing the titanium film treated in step c twice with deionized water, soaking for 2 minutes each time;

[0036] e. Put the titanium film cleaned in step d into the gelatin solution prepared in step b, soak for 20 minutes, and take it out;

[0037] f. Washing the titanium membra...

Embodiment 2

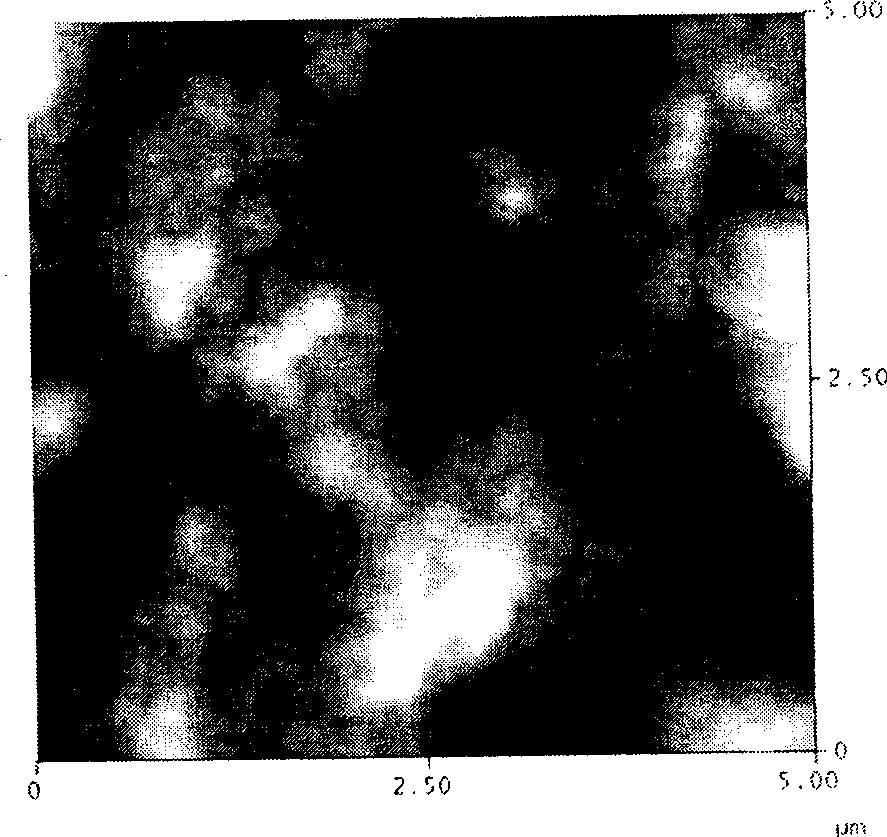

[0040] This embodiment is a layer-by-layer self-assembled modified titanium film, and its preparation method includes the following steps:

[0041] A, take chitosan 1.0g, add concentration and be 50mL of acetic acid solution of 10mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 2%;

[0042] b. Weigh 2.0 g of gelatin, add 25 mL of deionized water adjusted to a pH value of 11 with sodium hydroxide, and dissolve at a temperature of 45° C. to prepare a gelatin solution with a concentration of 8% by mass;

[0043] C, put titanium film in the chitosan solution that step a makes, soak for 20 minutes, take out;

[0044] d. Washing the titanium film treated in step c with deionized water for 3 times, soaking for 1 minute each time;

[0045] e. Put the titanium film cleaned in step d into the gelatin solution prepared in step b, soak for 10 minutes, and take it out;

[0046]f. Washing the titanium film treated in s...

Embodiment 3

[0049] This embodiment is a Ti-6Al-4V titanium alloy modified by layer-by-layer self-assembly, and its preparation method includes the following steps:

[0050] A, take chitosan 1.5g, add concentration and be 50mL of the acetic acid solution of 20mL / L, magnetic stirring makes dissolving for 20 minutes, makes the chitosan solution that mass percent concentration is 3%;

[0051] b. Weigh 1.5 g of gelatin, add 25 mL of deionized water whose pH value is adjusted to 11 with sodium hydroxide, and dissolve at a temperature of 45° C. to prepare a gelatin solution with a concentration of 6% by mass;

[0052] C, put titanium alloy in the chitosan solution that step a makes, soak for 15 minutes, take out;

[0053] d. Wash the titanium alloy processed by step c three times with deionized water, soaking for 1 minute each time;

[0054] e. Put the titanium alloy cleaned in step d into the gelatin solution prepared in step b, soak for 15 minutes, and take it out;

[0055] f, cleaning the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com