Method for preparing high energy liquid fuel by acid catalysis of norbornene dimerization

A liquid fuel, norbornene technology, applied in organic chemistry, addition of unsaturated hydrocarbons to hydrocarbons, explosives, etc., can solve the problems of unsuitable liquid fuels, high freezing point of dimers, unsuitable liquid fuels, etc. Easy, easy to recycle, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 500g of norbornene and 5g of aluminum trichloride were added into a 1000mL pressurized reactor with stirring, wherein the number of revolutions of the stirring was 500 rpm, and 500ppm of p-tert-butylcatechol was added, Seal it, heat it to a temperature of 150°C and react for 6 hours, filter it with a Buchner funnel to obtain a liquid mixture, move the liquid mixture to a distillation device, and collect fractions at a temperature of 105-115°C under a pressure of 50mmHg to obtain 430g of a colorless and transparent liquid fuel.

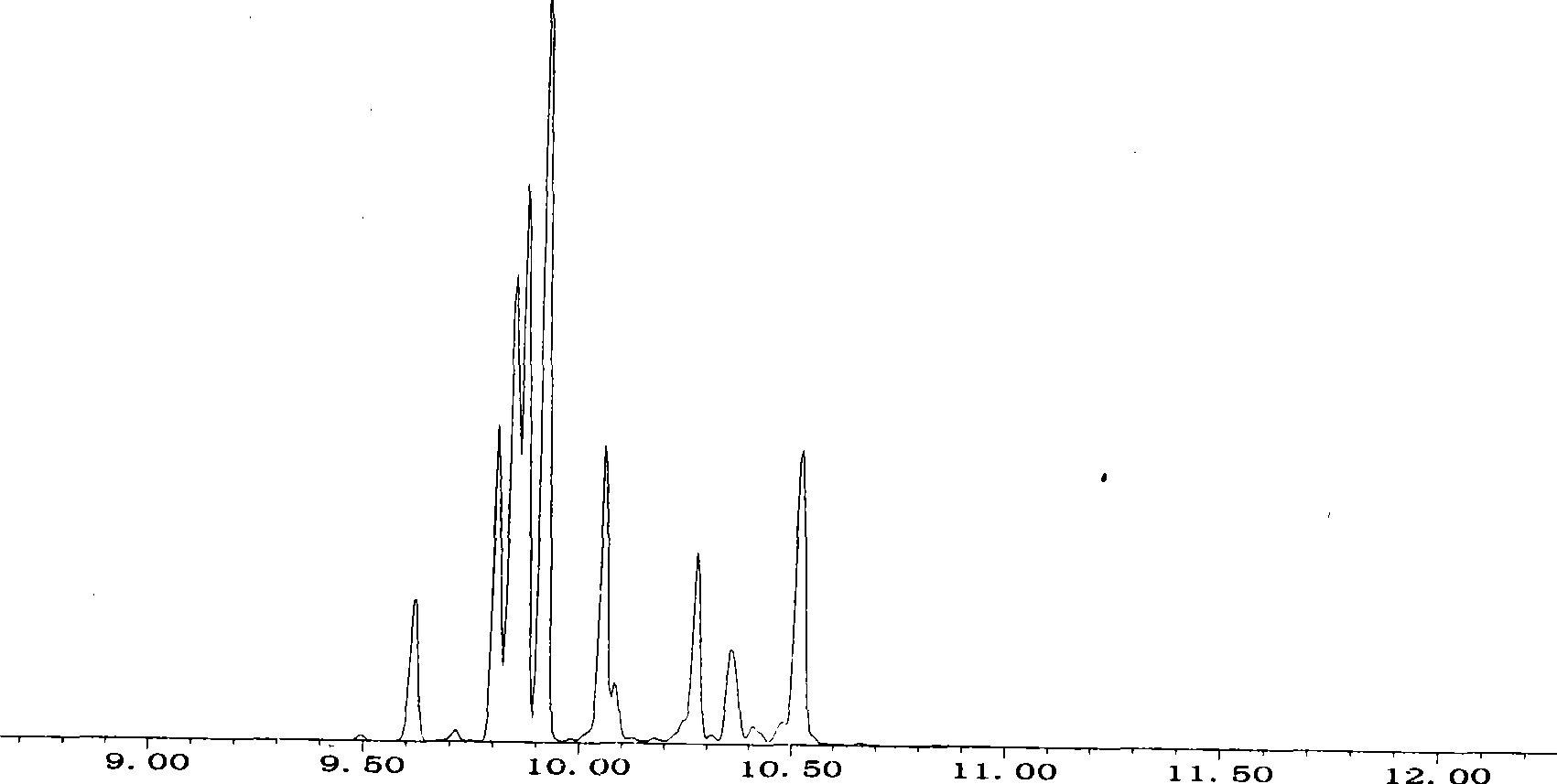

[0013] The prepared fuel is analyzed by gas chromatography, and the liquid jet fuel is composed of at least five isomers of norbornene dimers, and the total mass content is higher than 98%. It was determined that the density of the fuel was 1.04g / mL; the freezing point was -55°C; and the volume calorific value was 43.3MJ / L.

Embodiment 2-9

[0015] Same as Example 1, but using boron trifluoride, boric acid, trifluoromethanesulfonic acid, zinc chloride, sulfuric acid, phosphoric acid, hydrofluoric acid, nitric acid as catalyst respectively, with 2,5-di-tert-butyl-terephthalene Phenol is a polymerization inhibitor, and catalyst consumption, polymerization inhibitor consumption, temperature of reaction, reaction pressure, reaction time, and fuel output see the following table:

[0016] Example catalyst Catalyst quality temperature reflex Polymerization inhibitor Reaction time fuel production

[0017] 3 boric acid 15g 160℃ 800 6h 415g

Embodiment 10

[0019] 500g of norbornene and 100g of SO 4 2- / ZrO 2 Add it into a stirred pressurized reaction kettle with a volume of 1000mL, wherein the stirring speed is 550 rpm, and add hydroquinone with a mass content of 2500ppm, seal it, and heat it to a temperature of 190°C for 6 hours. The liquid mixture was obtained by filtering with a funnel, and the liquid mixture was moved to a distillation device, and the fraction with a temperature of 105-115°C was collected under a pressure of 60mmHg to obtain 415g of a colorless and transparent liquid fuel.

[0020] It was determined that the density of the prepared fuel was 1.02g / mL; the freezing point was -60°C; and the volume calorific value was 42.5MJ / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Volume calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com