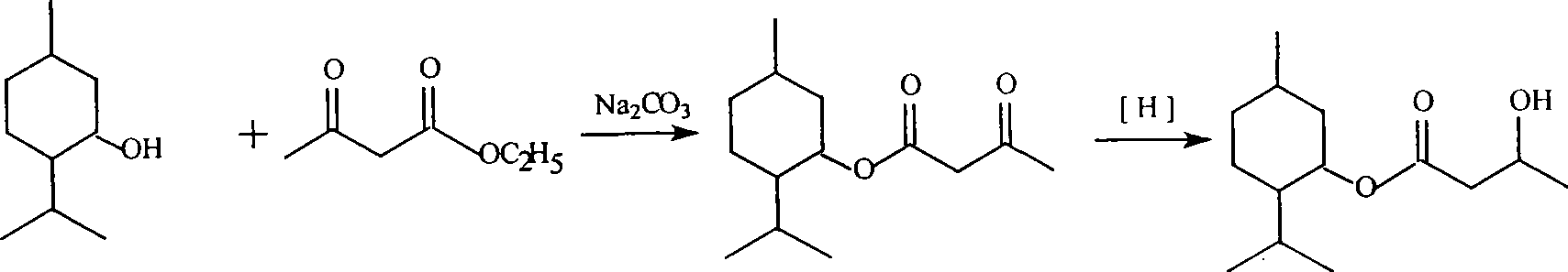

Method for synthesizing cooling agent L-menthyl 3-hydroxybutyrate

A technology for the synthesis of hydroxybutyric acid, which is applied in the preparation of ester groups and hydroxyl groups, organic chemistry, etc., can solve the problems of high cost, complicated operation, and low yield, and achieve simple operation, high yield, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further illustrated below by way of examples.

[0009] 1. Preparation of L-menthyl acetoacetate

[0010] In a 500 ml three-necked flask equipped with a distillation device, 65.0 g (0.50 mol) of ethyl acetoacetate, 93.6 g (0.60 mol) of L-menthol, 2.65 g (0.025 mol) of sodium carbonate and 150 ml of toluene were added. Heating and distillation, about 4-5 hours. After the reaction is complete, wash with water until neutral. Toluene was recovered, and the remaining liquid was distilled under reduced pressure to obtain 116.0 g (98.5%) of the product, with a yield of 95.3%.

[0011] 2. Preparation of L-menthyl 3-hydroxybutyrate

[0012] In a 500 ml three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 102.0 g (0.43 mol) of L-menthyl acetoacetate, 50 ml of methanol, cool to 10°C, and dropwise add 7.0 g (0.13 mol) of potassium borohydride. mol) and 35 ml of water, the dropwise addition temperature is controlled at 10-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com