Fiber-optic scanning head and driving method thereof

An optical fiber scanning and optical fiber technology, applied in medical science, diagnosis, endoscopy, etc., can solve the problems of low imaging signal-to-noise ratio and impact on imaging quality, achieve convenient coupling, increase line scanning range, and simple manufacturing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

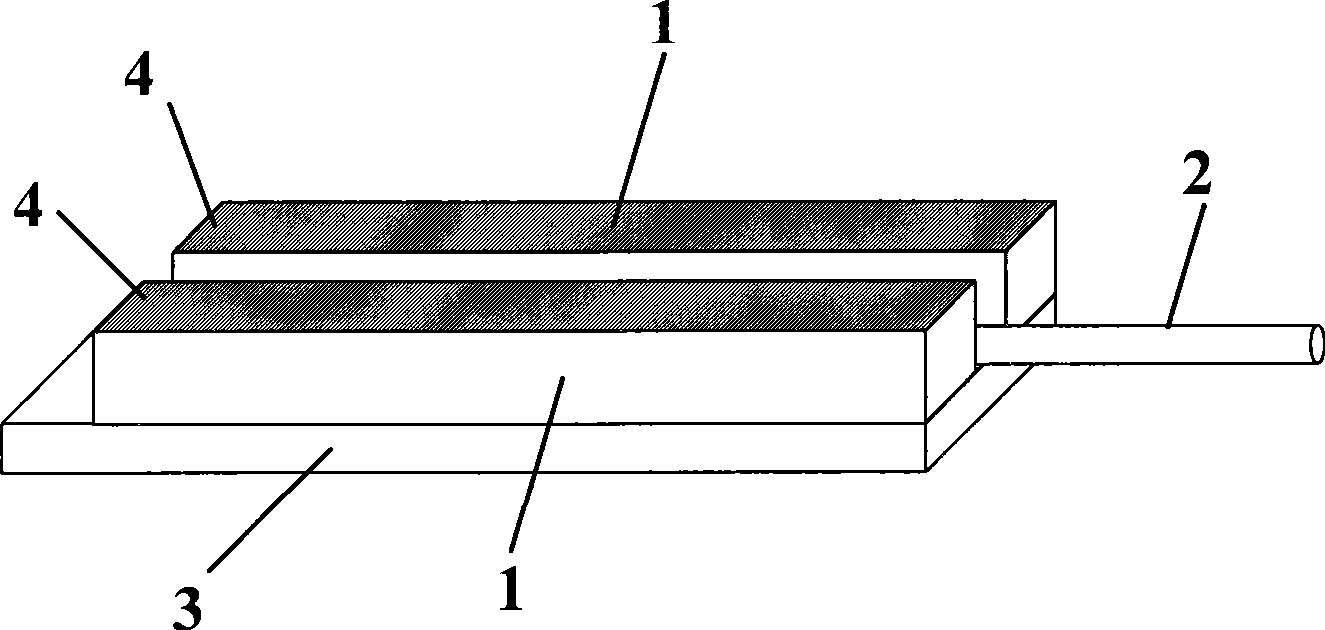

[0053] Embodiment 1: Fabrication of an optical fiber scanning probe. Proceed as follows

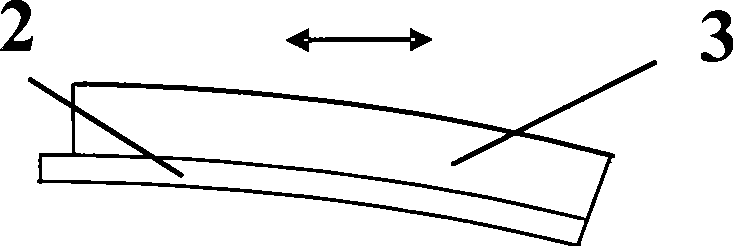

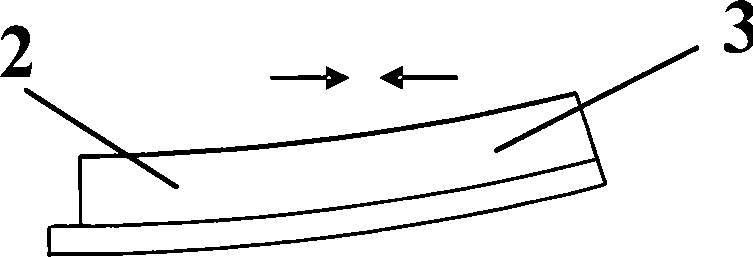

[0054] 1. Take two piezoelectric ceramic sheets 2 with a length of 50 mm, a width of 0.2 mm, and a thickness of 0.2 mm coated with an electrode layer 1 on one side, and a thin copper sheet 3 with a thickness of 53 mm in length, a width of 0.6 mm, and a thickness of 0.1 mm. One piece, using epoxy resin to bond two piezoelectric ceramic sheets 2 in parallel on the copper sheet 3, one end of the piezoelectric ceramic sheet 2 is flush with the end of the copper sheet 3, and the distance between the two piezoelectric ceramic sheets 2 is 0.2 mm.

[0055] 2. Remove the 30-40mm coating from the end of a single-mode optical fiber to expose the bare optical fiber 4, cut the end face of the optical fiber flat with an optical fiber cutter, place the optical fiber 4 in the gap between two piezoelectric ceramic sheets, and reserve a length of 10mm (The resonant frequency is about 1KHz) As the vibratio...

Embodiment 2

[0059] Embodiment 2: An endoscopic fluorescence imaging system is formed by using an optical fiber scanning probe. The schematic diagram of the endoscopic fluorescence imaging system is shown in Figure 9 shown.

[0060] 1. After the optical fiber scanning probe is manufactured as in the first step of the embodiment, it is inserted into a stainless steel tube 6 with a diameter of 2mm. One end of the stainless steel tube 6 is pre-installed with a micro-convex lens 7 for focusing the outgoing light of the optical fiber and collecting fluorescence.

[0061] 2. Adjust the position of the optical fiber scanning probe in the stainless steel tube 6 so that the axis of the optical fiber coincides with the optical axis of the lens 7, and adjust the distance between the optical fiber 4 and the lens 7 to a suitable distance, and then use epoxy resin 8 to connect the lead end of the optical fiber probe to the stainless steel tube 6 glued together.

[0062] 3. Put the signal leads of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com