A preparation method of graphitized carbon nano material

A technology of nanomaterials and graphitized carbon, which is applied in the field of preparation of carbon nanomaterials, can solve problems such as high cost and pollute the environment, and achieve the effects of low cost, simple preparation process and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

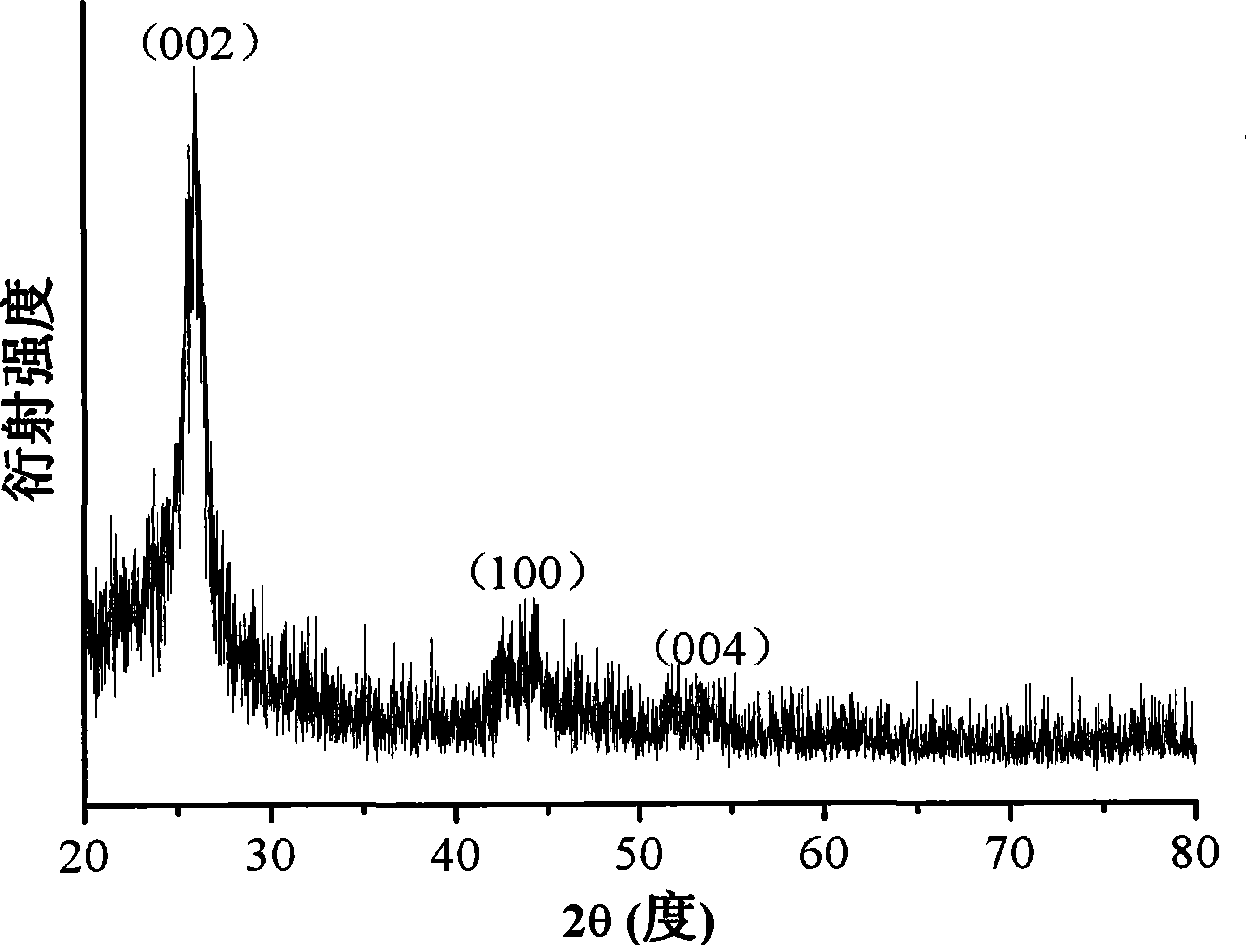

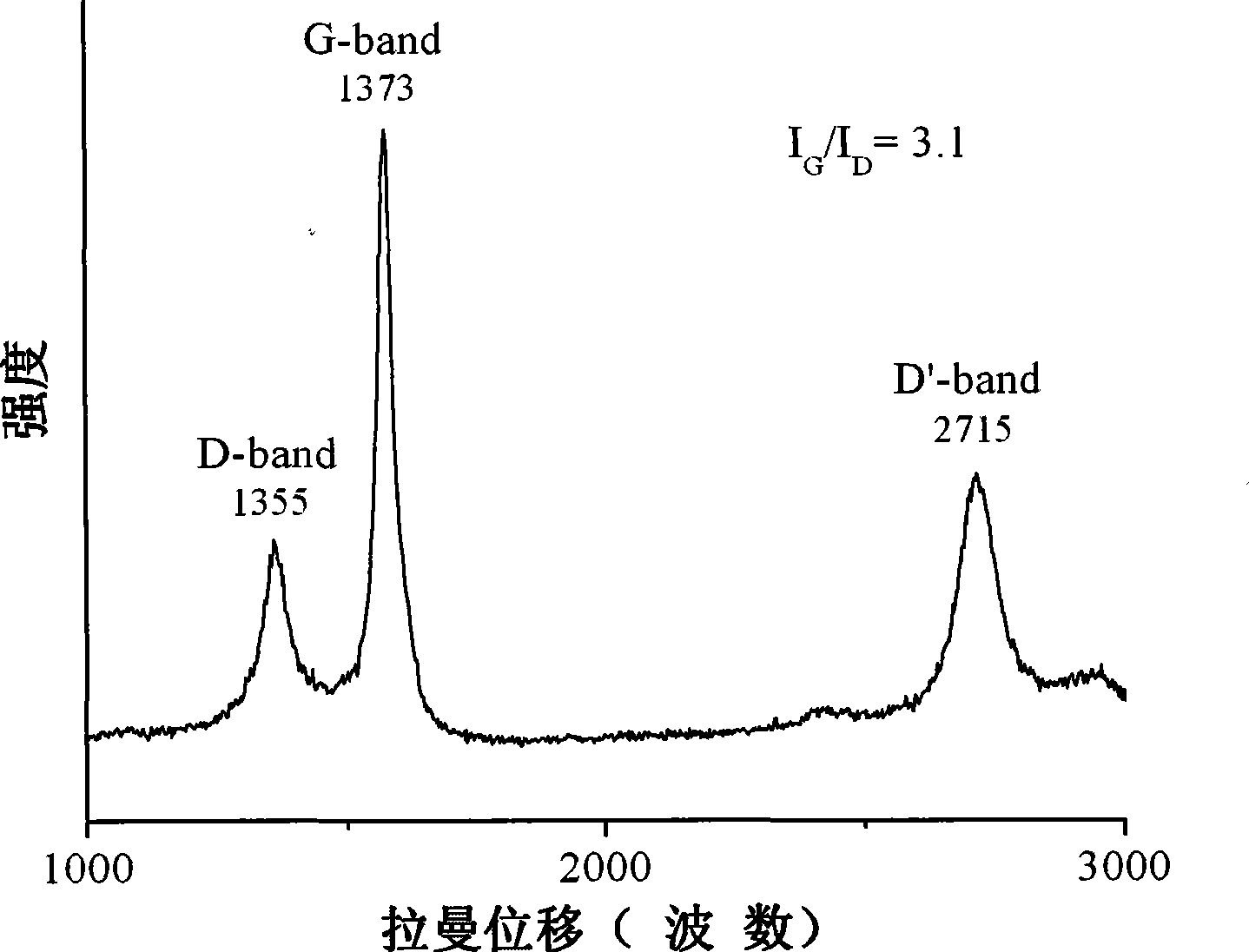

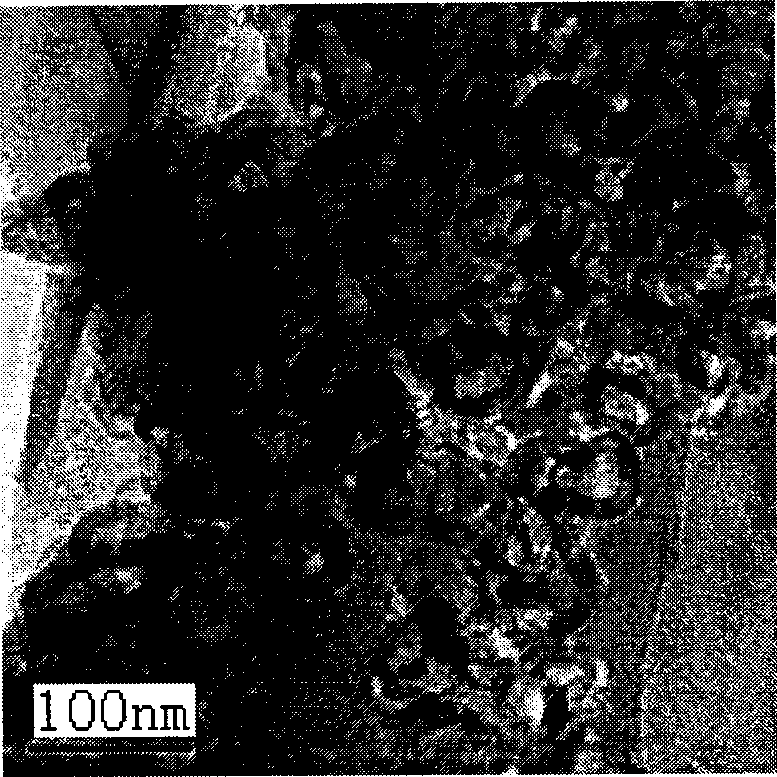

[0016] Specific Embodiment 1: The preparation method of graphitized carbon nanomaterials in this embodiment is completed by the following steps: 1. Pretreat the carbon source for 1 to 10 hours; 2. Add catalyst and pretreated carbon source to the solvent , stirring at 50°C and 100-300r / min stirring speed for 8h, wherein the mass ratio of carbon source to catalyst is 0.025-1:1; 3. Pre-carbonize the mixture in step 2 at a temperature of 80-450°C for 2-8h , the pre-carbonization atmosphere is air, oxygen, nitrogen, argon, helium or a mixture of several gases; 4. The temperature rises from room temperature to 400-1200°C at a rate of 1-15°C / min. Under the condition of heat treatment atmosphere, the heat treatment atmosphere flow rate is 30-2000mL / min, and the heat treatment temperature is 400-1200°C, heat-treat the product of step 3 for 10min-10h, wherein the heat treatment atmosphere is nitrogen, argon, helium, carbon monoxide, carbon dioxide, Hydrogen sulfide, hydrogen gas and a m...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the carbon source in Step 1 is agricultural and forestry crop extracts or agricultural and forestry wastes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 2 in that: the agricultural and forestry crop extract is glucose, sucrose, fructose or starch. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com