Preparation of high pure gold redrock nano-titanium dioxide

A technology of nano-titanium dioxide and rutile, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low crystallization temperature, long reaction time, co-precipitation of metal impurities, etc., achieve high efficiency, shorten heating time, and reaction time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

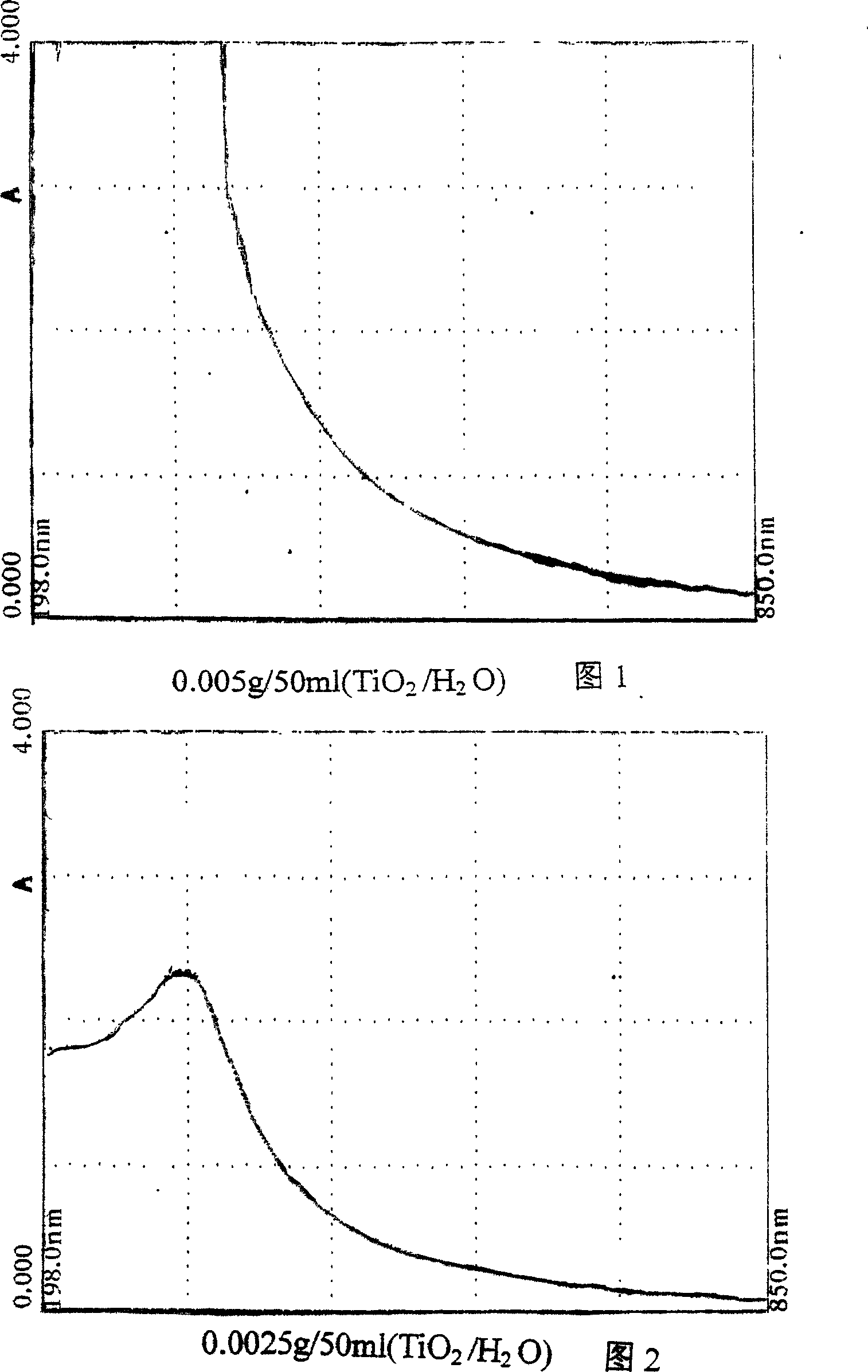

Image

Examples

example

[0017] Example: 1: Add 0.5mol / L titanium tetrachloride directly to the aqueous solution containing additives and 0.05mol hydroxylamine hydrochloride, add 0.1mol / L tetraethyl titanate to dissolve it, heat for 2.5 hours and cool down. The sol particles were tested by XRD to be complete rutile nano-titanium dioxide. The dispersion liquid is washed, dechlorinated, concentrated and dried to obtain a powder with a particle size of about 5nm and an iron content of less than 5ppm.

[0018] Example: 2: Add 0.5mol / L tetraethyl titanate directly into the water phase solution of Example 1, add 0.005mol / L hydrazine hydrate and concentrated hydrochloric acid to dissolve until the solution is transparent, heat and react, boil for 1.5 hours, cool, wash and dry, and the powder is passed through XRD test shows a single rutile nano-titanium dioxide with a particle size of 3-7nm, after sintering at 700 for 0.5-1 hour, the test particle size is 20-30nm, and the test iron content is 3-5ppm. XRD te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com