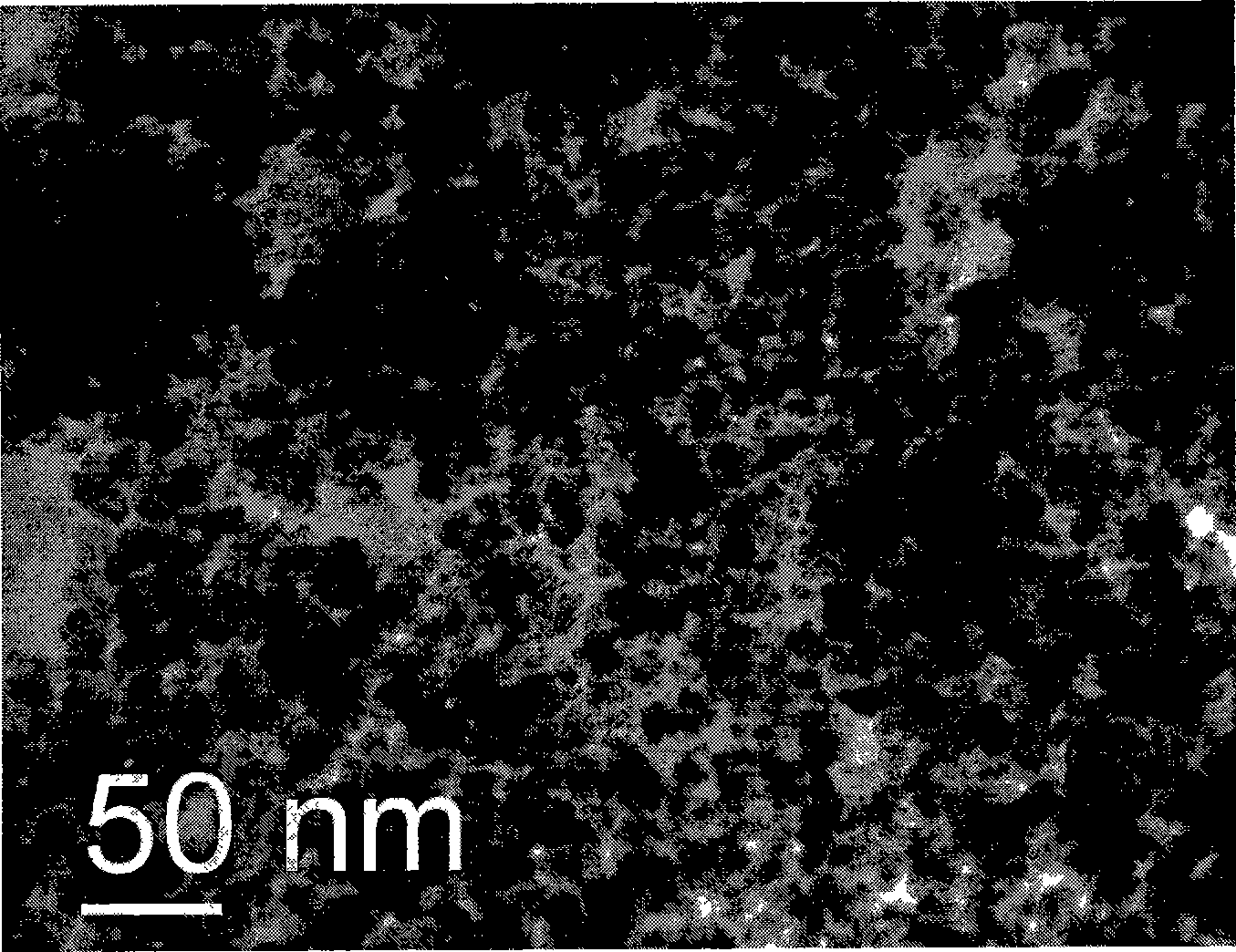

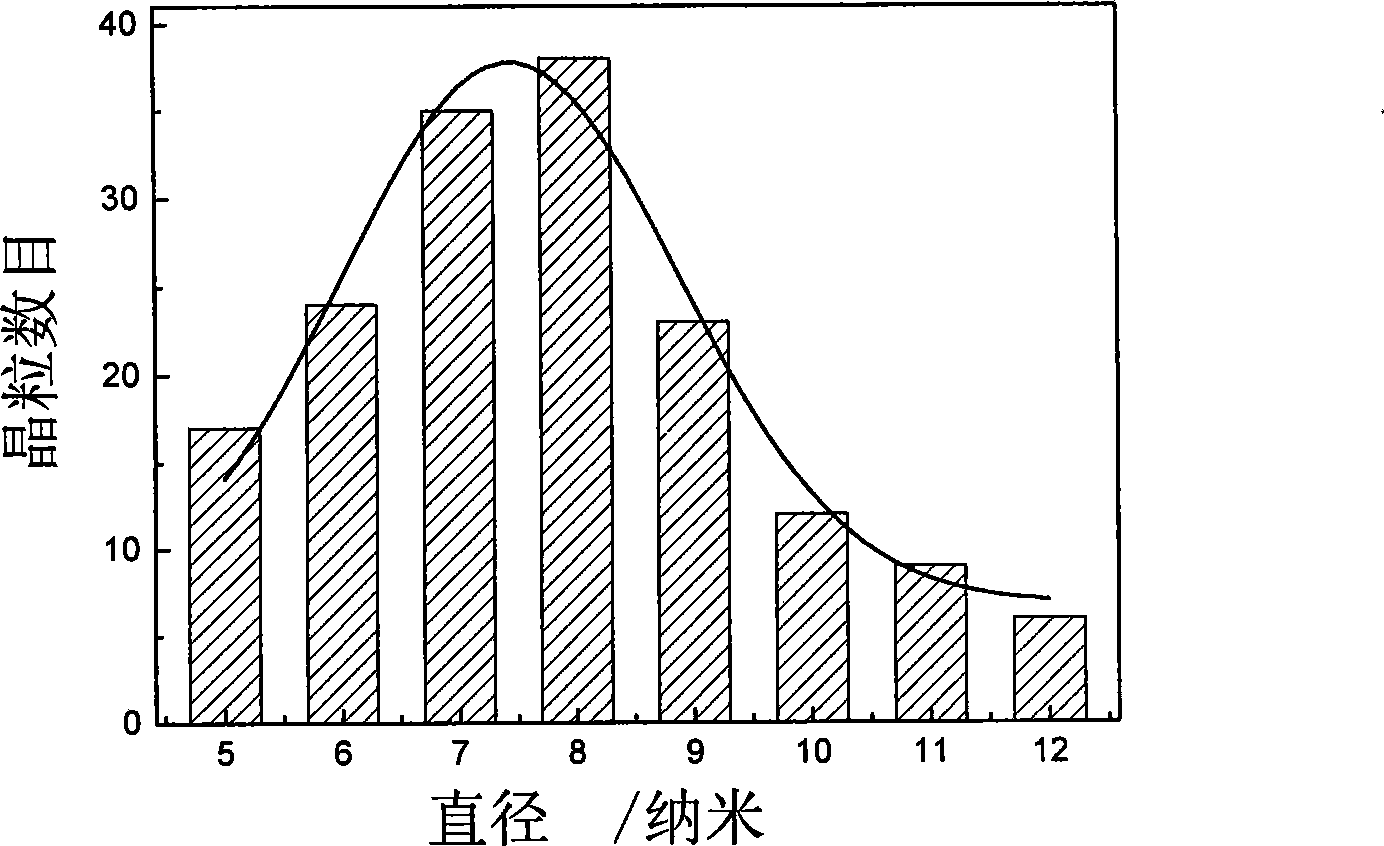

Nano-crystalline Fe*O* particles with high absorption capacity and preparation method thereof

A nano-crystal and nano-grain technology is applied in the field of material science to achieve the effects of improved adsorption capacity, high magnetization and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

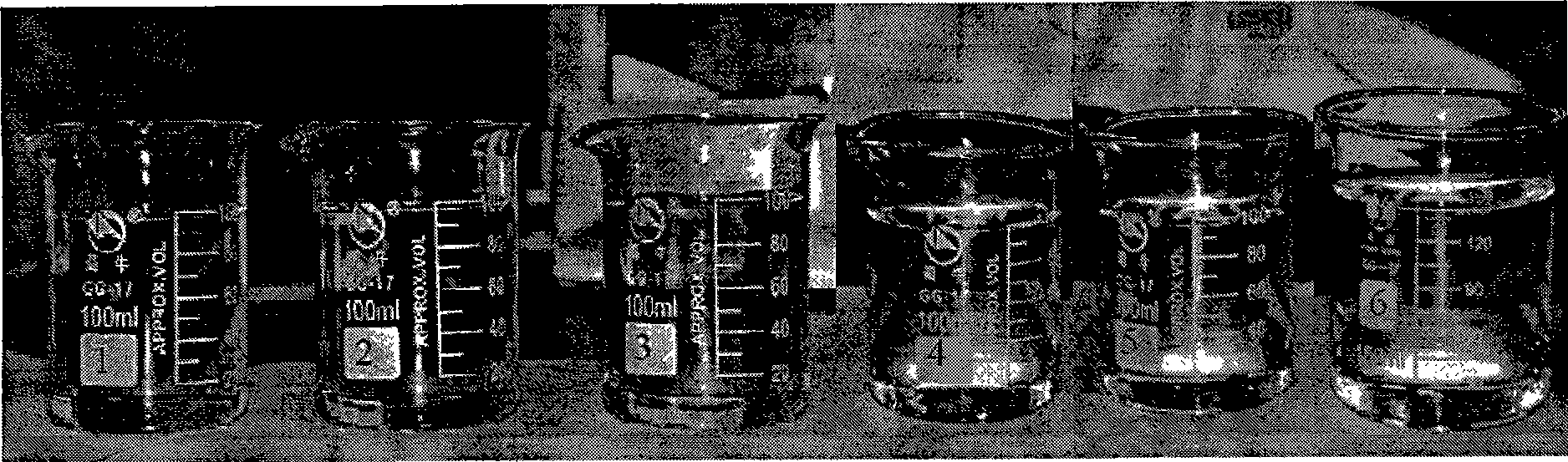

Embodiment 1

[0026] Prepare a mixed solution containing ferric ions and ferrous ions in a container, and Fe in the mixed solution 2+ with Fe 3+ The molar ratio of Fe 2+ : Fe 3+ =1:1.75, the concentration of all iron ions (ferric ions and ferrous ions) is 0.1mol / l, add precipitant ammonia solution under stirring and nitrogen atmosphere, the stirring speed is 800rpm, and the nitrogen flow rate is 2Nm 3 / h, the concentration of the ammonia solution is 0.5mol / l, the amount added is based on the pH of the mixed solution after adding the ammonia solution; after adding the ammonia solution, emit ultrasonic waves to the mixed solution for ultrasonic dispersion for 1h, the frequency of the ultrasonic wave is 20±1kHz, the power It is 80W.

[0027] After the ultrasonic dispersion is completed, seal the reaction container with plastic wrap, and open a nitrogen flow port on the plastic wrap; heat the reaction container to 60±5°C in a water bath, feed nitrogen into the reaction container and continue...

Embodiment 2

[0043] Prepare a mixed solution containing ferric ions and ferrous ions in a container, and Fe in the mixed solution 2+ with Fe 3+ The molar ratio of Fe 2+ : Fe 3+ =1:1.5, the concentration of all iron ions (ferric ions and ferrous ions) is 0.25mol / l, add precipitant ammonia solution under stirring and nitrogen atmosphere, the stirring speed is 700rpm, and the nitrogen flow rate is 1.5Nm 3 / h, the concentration of the ammonia solution is 1mol / l, the amount added is based on the pH of the mixed solution after adding the ammonia solution; after adding the ammonia solution, emit ultrasonic waves to the mixed solution for ultrasonic dispersion for 1.5h, the frequency of the ultrasonic wave is 20±1kHz, the power 50W.

[0044] After the ultrasonic dispersion is completed, seal the reaction container with plastic wrap, and open a nitrogen flow port on the plastic wrap; heat the reaction container to 60±5°C in a water bath, feed nitrogen into the reaction container and continue sti...

Embodiment 3

[0049] Prepare a mixed solution containing ferric ions and ferrous ions in a container, and Fe in the mixed solution 2+ with Fe 3+ The molar ratio of Fe 2+ : Fe 3+ =1:1.25, the concentration of all iron ions (ferric ions and ferrous ions) is 0.5mol / l, add precipitant ammonia solution under stirring and nitrogen atmosphere, the stirring speed is 1000rpm, and the nitrogen flow rate is 2.5Nm 3 / h, the concentration of the ammonia solution is 2mol / l, the amount added is based on the pH of the mixed solution after adding the ammonia solution; after adding the ammonia solution, emit ultrasonic waves to the mixed solution for ultrasonic dispersion for 2h, the frequency of the ultrasonic wave is 20 ± 1kHz, and the power is 20W.

[0050]After the ultrasonic dispersion is completed, seal the reaction vessel with plastic wrap, and open a nitrogen flow port on the plastic wrap; heat the reaction vessel to 60±5°C in a water bath, feed nitrogen into the reaction vessel and continue stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com