Al core/Al2O-based ceramic sheath self-healing composite foam thermal protection structure simulating capillary plexus and manufacture method thereof

A technology of capillary and composite foam, applied in ceramic products, other household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

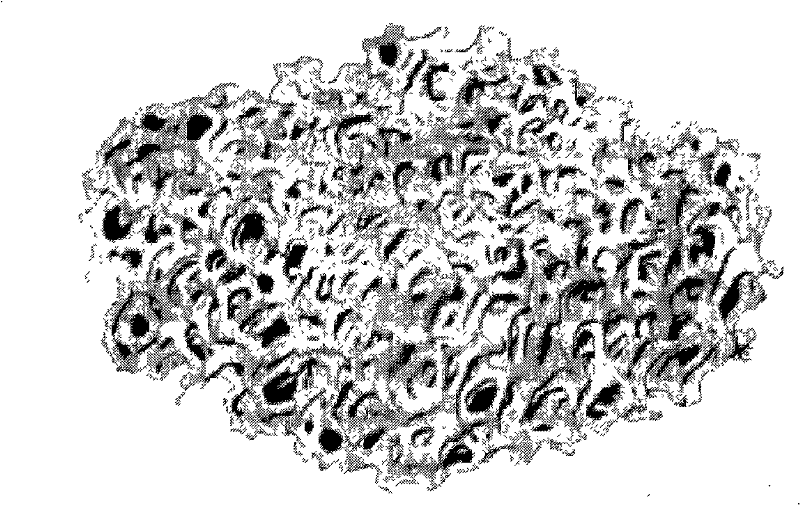

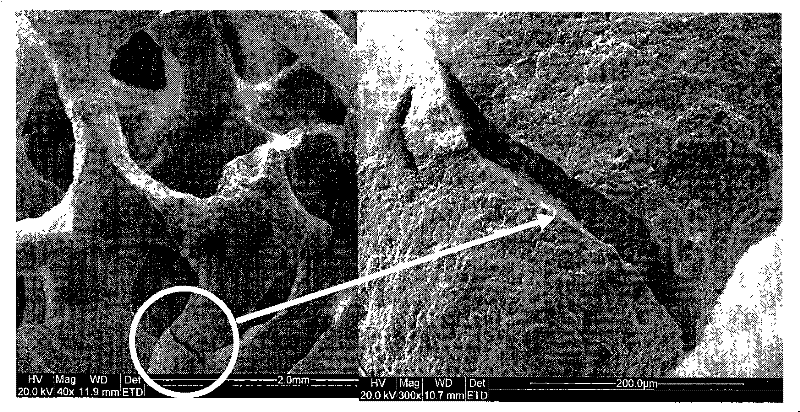

[0023] The metal foam used as a raw material is 6101 aluminum alloy with a size of 10mm×10mm×10mm. The main components of the metal are silicon 0.3-0.7%, magnesium 0.35-0.8% and a maximum content of iron 0.5%, and elements present in amounts of 0.1% or less include copper, zinc, boron, manganese and chromium. Aluminum foam is composed of three-dimensional randomly connected metal strips, which form an open microporous structure, and the outer surface of the strip defines three-dimensional randomly connected open channels.

[0024] Put the foamed aluminum after neutral degreasing in the electrolyte solution containing 8g / L NaSiO3 and 2g / L KOH at a temperature of 25°C, and after turning on the power, adjust the current so that the current density is 7A / dm 2 , the voltage is 200-600V, after 60 minutes of treatment, cut off the power supply, take it out, wash and dry it, and you can get a foam ceramic composite material with aluminum as the core and aluminum oxide as the sheath wr...

example 2

[0026] Other steps are the same as Example 1, except that the electrolyte becomes 26g / L NaSiO3, 10g / L KF, 8g / L KOH, 24ml ethylene glycol or glycerol, and the current density is 8A / dm 2 , the voltage is 300V.

[0027] The prepared Al core / Al2O3-based ceramic sheath composite foam structure imitating the capillary plexus has the following characteristics: figure 1 Described structural features. Compression deformation is used to prefabricate cracks in the above foam structure, and then it is kept at 1100°C for 1 hour, and the molten Al at 1400°C seeps out and oxidizes to form a dense Al2O3 layer that scabs and heals the prefabricated cracks on the Al203-based ceramic sheath.

example 3

[0029] Other steps are the same as Example 1, except that the electrolyte becomes 20g / L NaAlO2, 6g / L KF, and the current density is 7A / dm 2 , the voltage is 240V.

[0030] The prepared Al core / Al2O3-based ceramic sheath composite foam structure imitating the capillary plexus has the following characteristics: figure 1 Described structural features. Compression deformation is used to prefabricate cracks in the above foam structure, and then it is kept at 1200°C for 0.5 hours, and the molten Al at 1400°C seeps out and oxidizes to form a dense Al2O3 layer that scabs and heals the prefabricated cracks on the Al2O3-based ceramic sheath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com