Method for epitaxial growth of nitride films

A technology of epitaxial growth and nitride, which is applied in the field of semiconductors, can solve the problems of affecting material crystal quality, material crystal quality deterioration, low mobility, etc., and achieve the effect of improving crystal quality and uniformity, reducing growth time, and improving growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

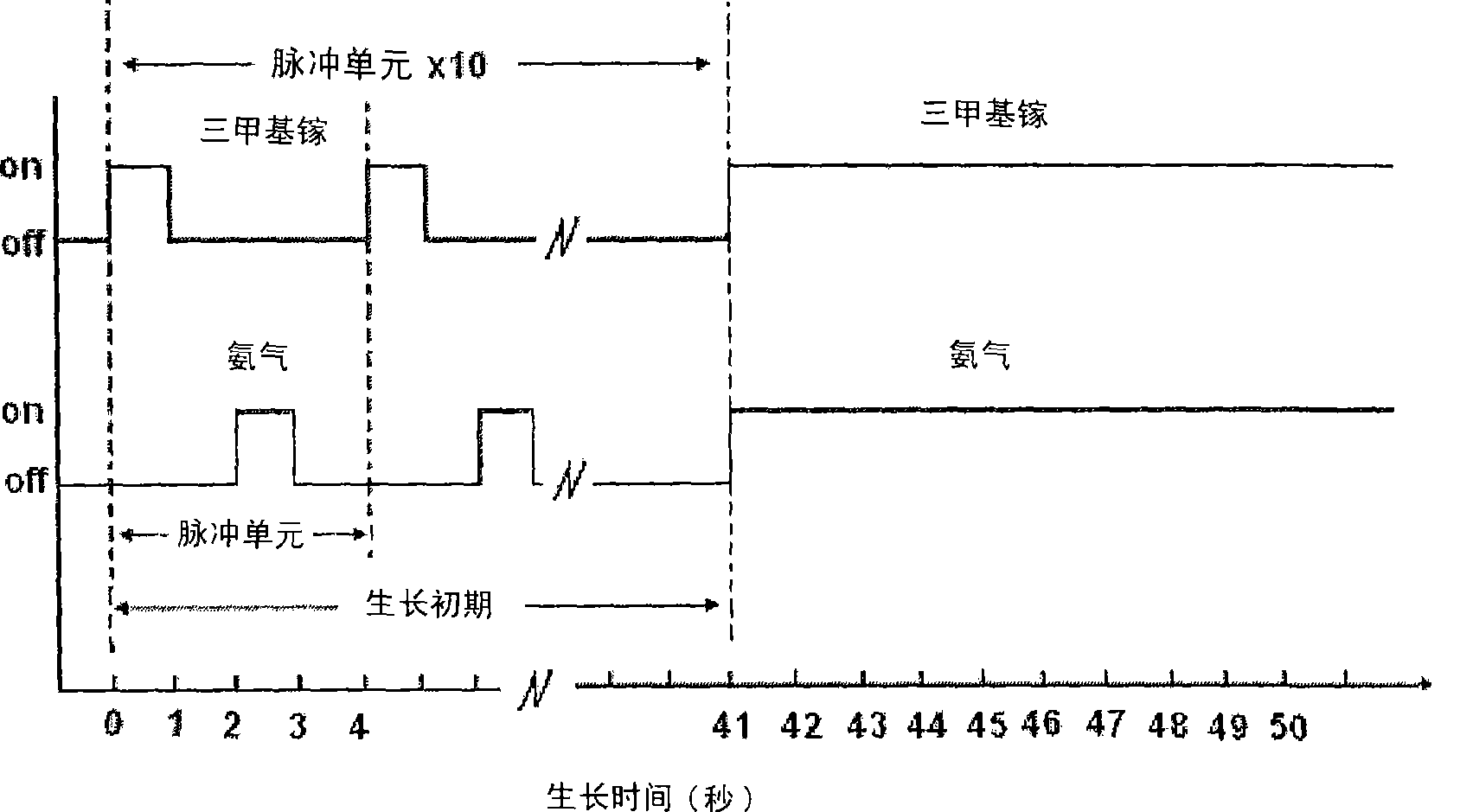

[0022] This embodiment provides a method for growing a gallium nitride thin film with high crystal quality on a sapphire substrate by using MOCVD equipment. The epitaxial equipment used is a commercial machine produced by VECOO Company of the United States, the model is D150. The V group source used is ammonia (NH3), the group III source material is trimethylgallium (TMG), the carrier gas is N2 and H2, and the flow rates of NH3 and TMG are 10 standard liters per minute (slm) and 100 micromoles, respectively. / min (μmol / m). The pressure of the reaction chamber is 150 Pascals (Pa).

[0023] The method for the epitaxial growth of the nitride thin film comprises the following steps:

[0024] First, put the 2-inch sapphire substrate into the MOCVD growth equipment.

[0025] Then raise the temperature of the sapphire substrate to 1100°C, and heat-treat the substrate for 10 minutes in a flowing H2 atmosphere to form an atomic step structure on the sapphire surface;

[0026] Then ...

Embodiment 2

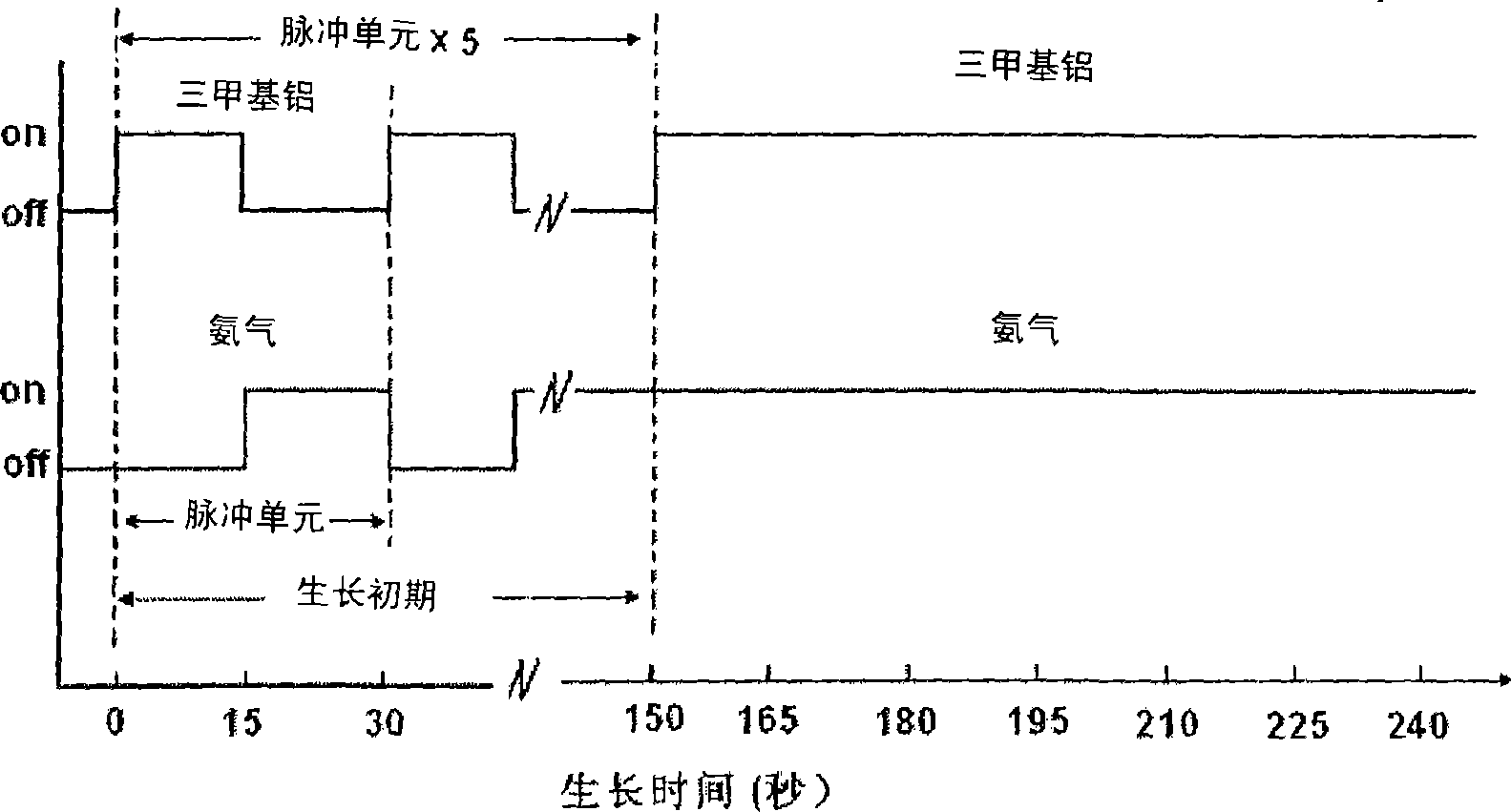

[0030] This embodiment provides a method for growing a high-quality aluminum nitride epitaxial layer on a sapphire substrate by using MOCVD equipment. The epitaxial equipment used is a commercial machine produced by VECOO Company of the United States, the model is D150. The source of group V used is ammonia (NH3), the source material of group III is trimethylaluminum (TMA), the carrier gas is N2 and H2, and the flow rates of NH3 and TMA are 0.5 standard liters per minute (slm) and 33 micromoles, respectively / min (μmol / m). The pressure of the reaction chamber is 75 Pascals (Pa).

[0031] The method for the epitaxial growth of the nitride thin film comprises the following steps:

[0032] First put the 2-inch sapphire substrate into the MOCVD growth equipment.

[0033] Then raise the temperature of the substrate to 1150°C, and heat-treat the substrate for 10 minutes in a flowing H2 atmosphere to form an atomic step structure on the surface;

[0034] In the subsequent growth ...

Embodiment 3

[0038] This embodiment provides a method for growing a high-quality aluminum gallium indium nitride (AlGaInN) epitaxial layer on a sapphire substrate by using MOCVD equipment. The epitaxial equipment used is a commercial machine produced by VECOO Company of the United States, the model is D150. The V group source used is ammonia (NH3), and the group III source materials are trimethylgallium (TMG), trimethylaluminum (TMA) and trimethylindium (TMI). The carrier gas is N2 and H2, and the pressure of the reaction chamber is 150 Pascal (Pa).

[0039] The method for the epitaxial growth of the nitride thin film comprises the following steps:

[0040] First, load the MOCVD growth equipment on the 2-inch sapphire substrate.

[0041] Then the temperature of the substrate was raised to 1100°C, and the substrate was heat-treated for 10 minutes in a flowing H2 atmosphere to form an atomic step structure on the surface;

[0042] Then lower the temperature of the substrate to 800°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com