Preparation of novel whitening sunscreen agent-dioctyl ferulae and application

A technology of octyl ferulate and isooctyl ferulate is applied in the field of preparation of a new type of whitening sunscreen agent - octyl ferulate, which can solve the problems of strong hydrophilicity and poor fat solubility, and achieve easy availability of raw materials and low price. Low, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

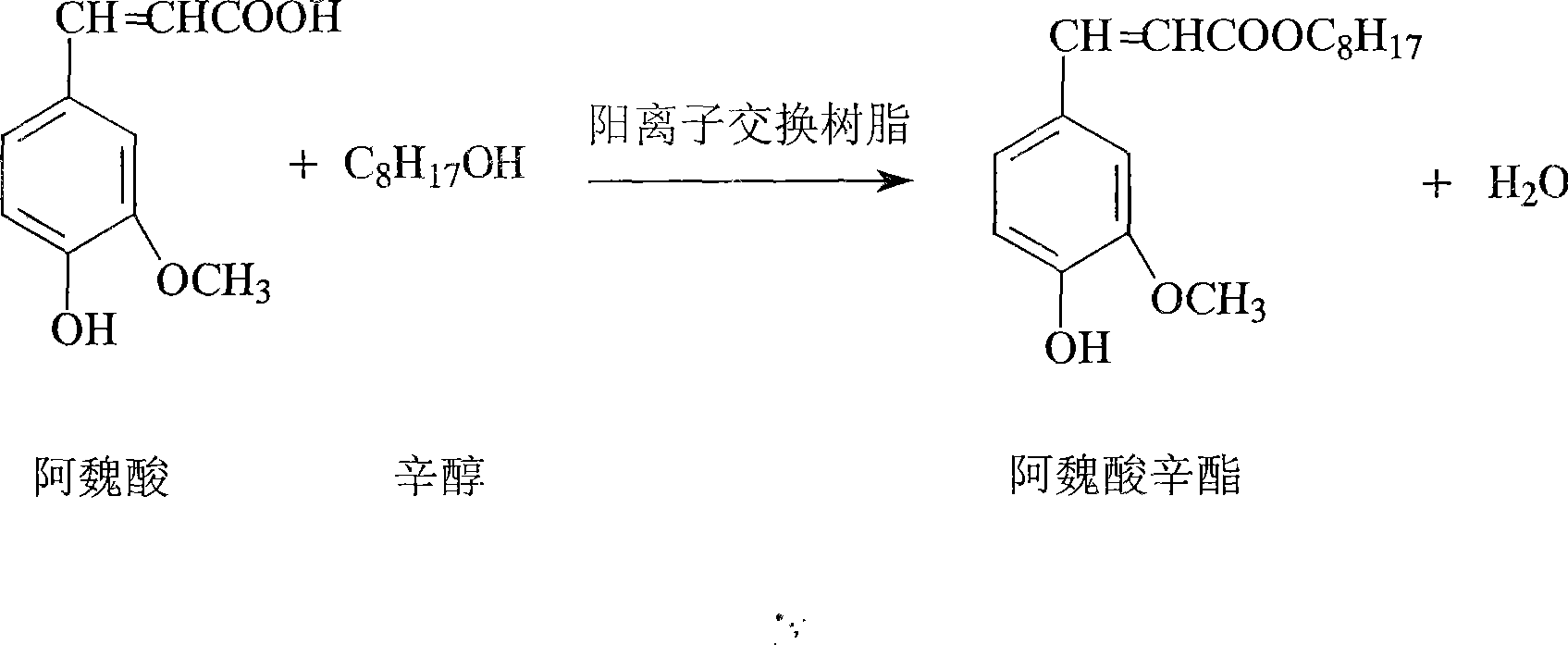

[0016] Example 1 Preparation of n-octyl ferulate (direct heating and reflux method)

[0017] Add ferulic acid into a reactor equipped with a stirrer, a thermometer, a reflux condenser and a water separator, and slowly add n-octanol and benzene under stirring. Heat with low heat and stir to dissolve the solid. After the solid is dissolved, the cation exchange resin is slowly added dropwise in batches, the temperature is slowly raised, and the stirring is maintained at a constant speed. When the temperature reaches about 85°C, reflux begins and keeps refluxing for 1-5 hours. After the material in the bottle is clarified, reflux is maintained for 1-2 hours until no more water is formed, and the reaction ends. Then cool to room temperature, add an appropriate amount of NaHCO3 saturated solution to neutralize, stand still to separate the organic layer, dry the organic layer with anhydrous calcium chloride, separate the layers, distill under reduced pressure to remove unreacted n-octano...

Embodiment 2

[0018] Example 2 Preparation of n-octyl ferulate (microwave method)

[0019] Ferulic acid is added to a reactor equipped with a stirrer, a thermometer, a reflux condenser and a water separator, and n-octanol, benzene, and cation exchange resin are slowly added under stirring. The reactor is irradiated with microwave (200-600W) for 20-30 minutes, and the reaction is over. Then cool to room temperature, add an appropriate amount of NaHCO3 saturated solution to neutralize, stand still to separate the organic layer, dry the organic layer with anhydrous calcium chloride, separate the layers, distill under reduced pressure to remove unreacted n-octanol to obtain a light yellow liquid, that is It is the n-octyl ferulic acid compound described in the present invention.

Embodiment 3

[0020] Example 3 Preparation of isooctyl ferulate (direct heating and reflux method)

[0021] Add ferulic acid into a reactor equipped with a stirrer, a thermometer, a reflux condenser and a water separator, and slowly add isooctyl alcohol and benzene under stirring. Heat with low heat and stir to dissolve the solid. After the solid is dissolved, the cation exchange resin is slowly added dropwise in batches, the temperature is slowly raised, and the stirring is maintained at a constant speed. When the temperature reaches about 85°C, reflux begins and keeps refluxing for 1-5 hours. After the material in the bottle is clarified, reflux is maintained for 1-2 hours until no more water is formed, and the reaction ends. Then cool to room temperature, add an appropriate amount of NaHCO3 saturated solution to neutralize, stand still to separate the organic layer, dry the organic layer with anhydrous calcium chloride, separate the layers, distill under reduced pressure to remove unreacted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com