Spray finishing material with disinfecting and sterilizing functions

A disinfection and sterilization, functional technology, applied in the directions of disinfectants, biocides, animal repellants, etc., can solve the problems of short effective time of sterilization and disinfection, unsuitable for use in public places, heavy smell of disinfectants, etc., to achieve a wide range of applications , Easy to clean, easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepared according to the following components: 20% polyhexamethylene biguanide PHMB thickener hydroxypropyl methylcellulose 0.5%; chelating agent EDTA 0.1%; surfactant C 13 Alcohol 7EO 0.1%, water 94.3%.

[0047] Preparation method:

[0048] Add 40-50% of 65-75 DEG C water into chelating agent EDTA and thickener hydroxypropyl methylcellulose and stir evenly. When cooling to 20-30°C, add polyhexamethylene biguanide PHMB and surfactant C 13 Stir alcohol 7EO, essence and remaining deionized water evenly. Let it stand and filter to obtain a transparent and uniform liquid.

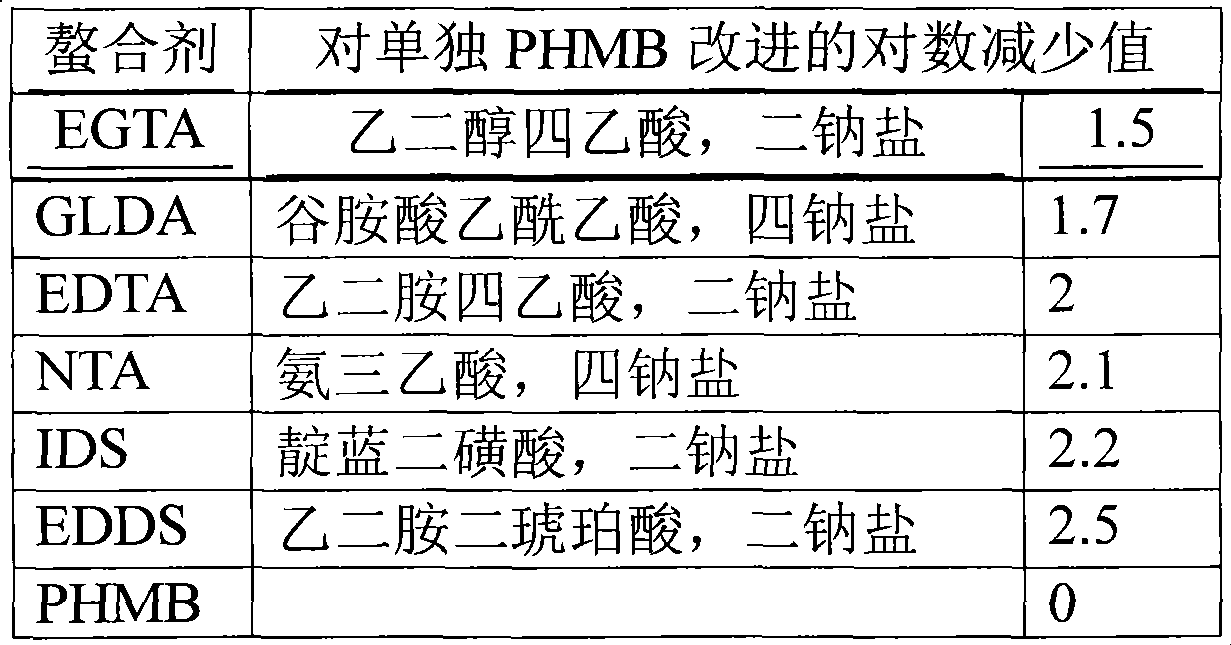

[0049] Under EN1040:1997, in the test against Pseudomonas aeruginosa, compared with PHMB alone, PHMB combined with chelating agent showed a significant improvement in bactericidal activity, about 30-300 times higher. See Table 1.

Embodiment 2

[0051] Prepared according to the following components: 20% polyhexamethylene biguanide PHMB 15%; thickener hydroxyethyl cellulose 3.%; chelating agent glutamic acid tetrasodium acetoacetate 3%; surfactant sorbose Alcohol Monolaurate 20EO 3%, Water 76%.

[0052] Preparation method: with embodiment 1.

[0053] The transparent uniform liquid can be sprayed with common spraying equipment (such as household sprayer) to form a layer of transparent film.

Embodiment 3

[0055] Prepare according to the following components

[0056] 20% polyhexamethylene biguanide PHMB 20%; hydroxypropyl cellulose 3%; chelating agent ethylenediamine disuccinate disodium salt 1.5%; surfactant ethylenediamine triacetate cocoalkylacetamide 1 %, water 74.5%.

[0057] Preparation method: with embodiment 1.

[0058] After the above solution was kept in the dark for a period of 12 months, the active ingredient concentration decreased from the initial 5% to about 4.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com