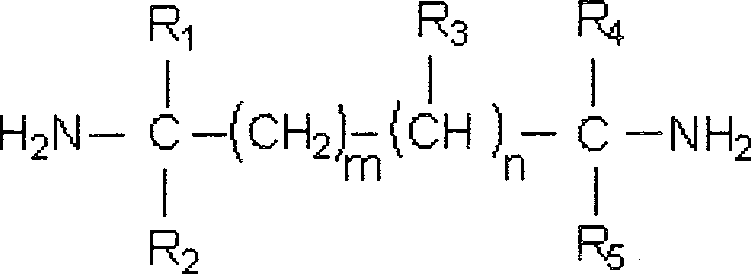

Modified polyamide thermosol based on polyester and preparation thereof

A polyamide hot-melt adhesive and polyester modification technology, applied in the direction of adhesives, etc., can solve the problems of long open time and achieve the effects of short open time, shortened open time, and excellent high-temperature washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 1.0L autoclave with stirrer, inlet pipe, exhaust pipe, temperature and pressure testing device, add 2-methyl adipic acid (80.0g), suberic acid (52.2g), sebacic acid in sequence (20.2g), 1-hexanoic acid (5.8g), 1-nonanoic acid (7.9g), 1,4-dimethylbutanediamine (35.4g), 3-ethyl-1,6-hexanediamine (29.2g), 3,4,5-trimethyl-1,9-nonanediamine (80.8g), 2,3-dimethyldecanediamine (30.3g), caprolactam (11.3g), 8- Capryllactam (28.2g), 2,6-di-tert-butyl-p-cresol (0.38g), water (14.4g), are replaced with nitrogen and vacuumized to remove the air in the kettle as far as possible, and then add nitrogen again to make the The internal pressure reaches 0.5Mpa, raise the temperature to 190°C, and control the pressure to 1.0Mpa, keep the temperature for 4.0 hours, reduce the pressure to 0.10Mpa, and add copolyester (29.0g) with an average molecular weight of 8100 and react for 2.0 hours, then cool down to 165 °C, reduce the pressure to 40kPa and dehydrate for 1.0 hour, then add nitro...

Embodiment 2

[0031] In a 1.0L autoclave with stirrer, inlet pipe, exhaust pipe, temperature and pressure testing device, add 2-ethyl adipic acid (43.5g), suberic acid (43.5g), azelaic acid in sequence (56.4g), sebacic acid (40.4g), 1-hexanoic acid (5.8g), 2-octanoic acid (4.3g), 1,4-dimethylbutanediamine (23.6g), 1,3-di Ethyl-butanediamine (36.5g), 3-isopropyl-pentamethylenediamine (51.1g), 3,4,5-trimethylnonanediamine (50.5g), ω-amino undecylidene acid ( 28.2g), 2,6-di-tert-butyl-p-cresol (0.24g), water (12.2g), replace and vacuumize with nitrogen, remove the air in the kettle as much as possible, then add nitrogen again to make the internal pressure reach 0.6Mpa, heat up to 210°C, and control the pressure to 1.5Mpa, keep the temperature for 2.0 hours, reduce the pressure to 0.10Mpa, add copolyester JCC-140 (36.5.0g) and heat up to 250°C for 1.5 hours, cool down to 170°C, depressurize to 60kPa and dehydrate for 2.0 hours, then add nitrogen and discharge under its protection to obtain a c...

Embodiment 3

[0033]In the autoclave with agitator, inlet pipe, exhaust pipe, temperature and pressure testing device, add 2-methyladipic acid (48.0g), 2-ethyladipic acid (43.5g), 3 -methyl suberic acid (37.6g), sebacic acid (40.4g), 1-hexanoic acid (5.8g), 1-decanoic acid (8.6g), 1,3-diethyl-butylene diamine (29.2 g), 3-ethylhexamethylenediamine (43.8g), 3,4,5-trimethylnonanediamine (40g), 2,3-dimethyldecanediamine (40.4g), 8-octyl Amide (14.1g), ω-aminoundecylidene acid (54.9g), 2,6-di-tert-butyl p-cresol (0.284g), water (10.0g), replaced with nitrogen and evacuated, as far as possible Remove the air in the kettle, then add nitrogen again to make the internal pressure reach 0.6Mpa, raise the temperature to 230°C, and control the pressure to 2.0Mpa, keep the temperature for 4.0 hours, reduce the pressure to 0.10Mpa, and add copolyester JCC-115 (50.0 g) and react for 2.0 hours, lower the temperature to 180°C, depressurize to 50kPa and dehydrate for 2.0 hours, then add nitrogen and discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com