Equiaxed grain refinement of titanium silicon binary alloy microscopic constitution

A binary alloy and microstructure technology, which is applied in the field of heat treatment of titanium-silicon binary alloy materials, can solve problems affecting the performance of the alloy, uneven grain distribution and size, etc., with flexible methods and a wide range of size selection , The treatment process is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

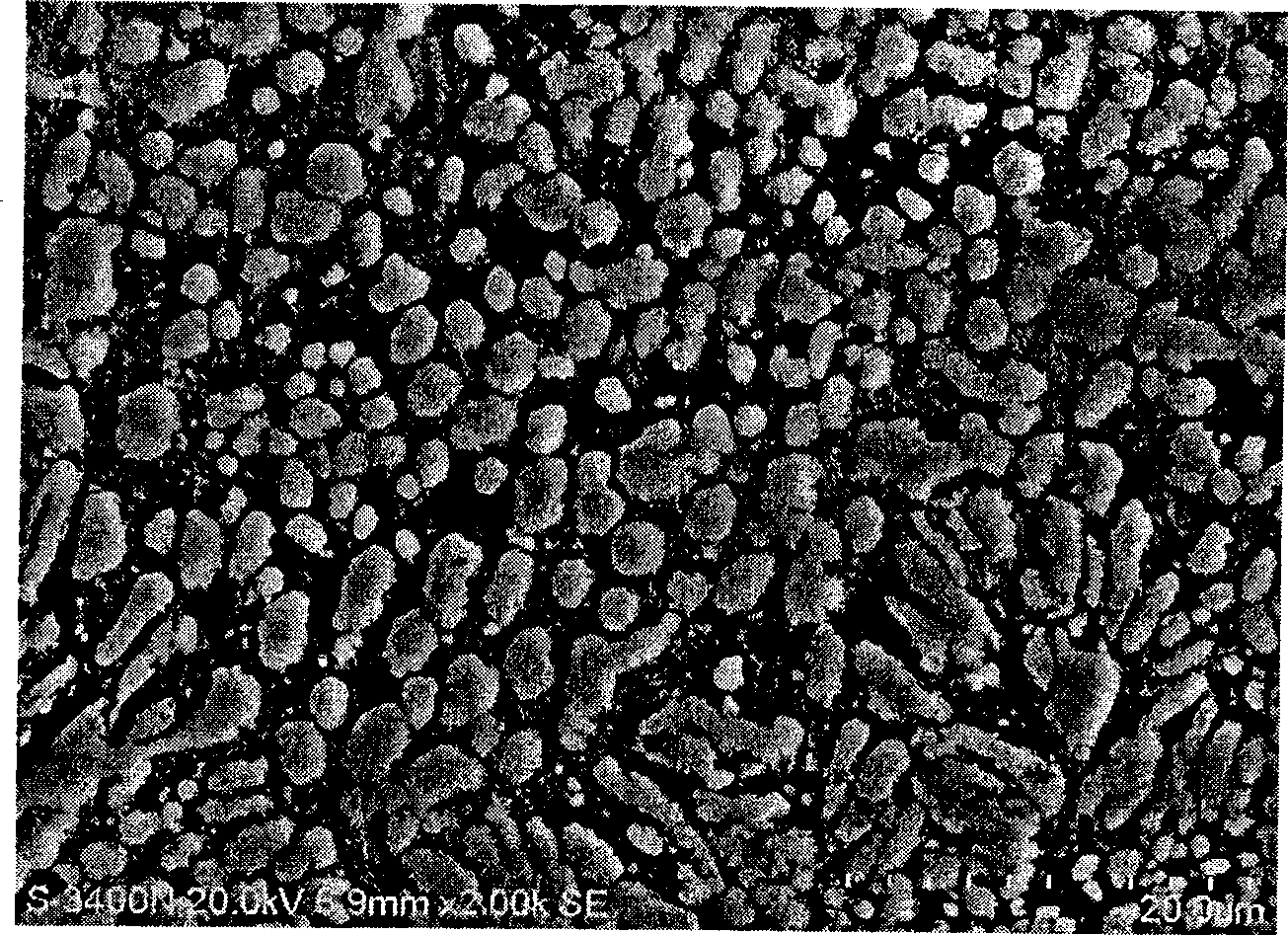

[0022] Put the bulk Ti-13.67Si (at%) eutectic cast alloy into the resistance furnace, then raise the temperature in the resistance furnace cavity from room temperature to 1100 °C at a rate of 5 °C per minute, and increase the temperature at 1100 °C After maintaining the temperature at ℃ for 120 minutes, turn off the power supply of the resistance furnace, and allow the alloy material to cool down to room temperature with the furnace. Ti in microstructure of alloy after treatment 5 Si 3 The phase transition becomes nearly equiaxed, and the average grain diameter is refined to 1-6 μm. The scanning electron microscope photos of its microstructure are shown in figure 1 . The hardness of the alloy was tested with HV-3 Vickers hardness tester. Under the same test conditions, the hardness of the treated alloy was 31HV higher than that of the as-cast alloy.

Embodiment 2

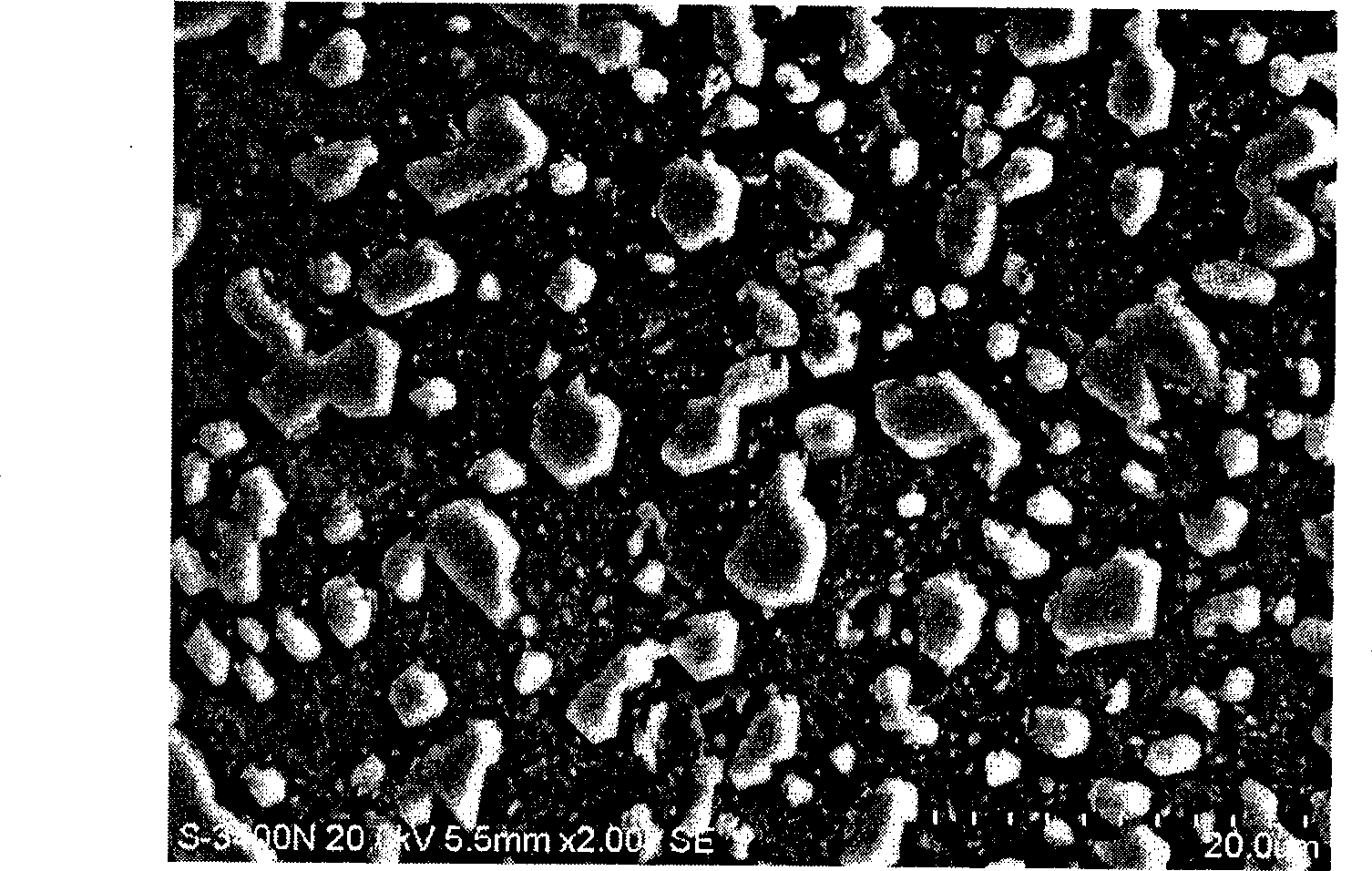

[0024] Put the bulk Ti-13.67Si (at%) eutectic cast alloy into the resistance furnace, then raise the temperature in the resistance furnace chamber from room temperature to 1200 °C at a rate of 5 °C per minute, and then increase the temperature at 1200 °C After maintaining the temperature at ℃ for 120 minutes, turn off the power supply of the resistance furnace, and allow the alloy material to cool down to room temperature with the furnace. Ti in microstructure of alloy after treatment 5 Si 3 The phase transition becomes nearly equiaxed, and the average grain diameter is refined to 1-8 μm. The scanning electron micrographs of the microstructure are shown in figure 2 . The hardness of the alloy was tested with HV-3 Vickers hardness tester. Under the same test conditions, the hardness of the treated alloy was 56HV higher than that of the as-cast alloy.

Embodiment 3

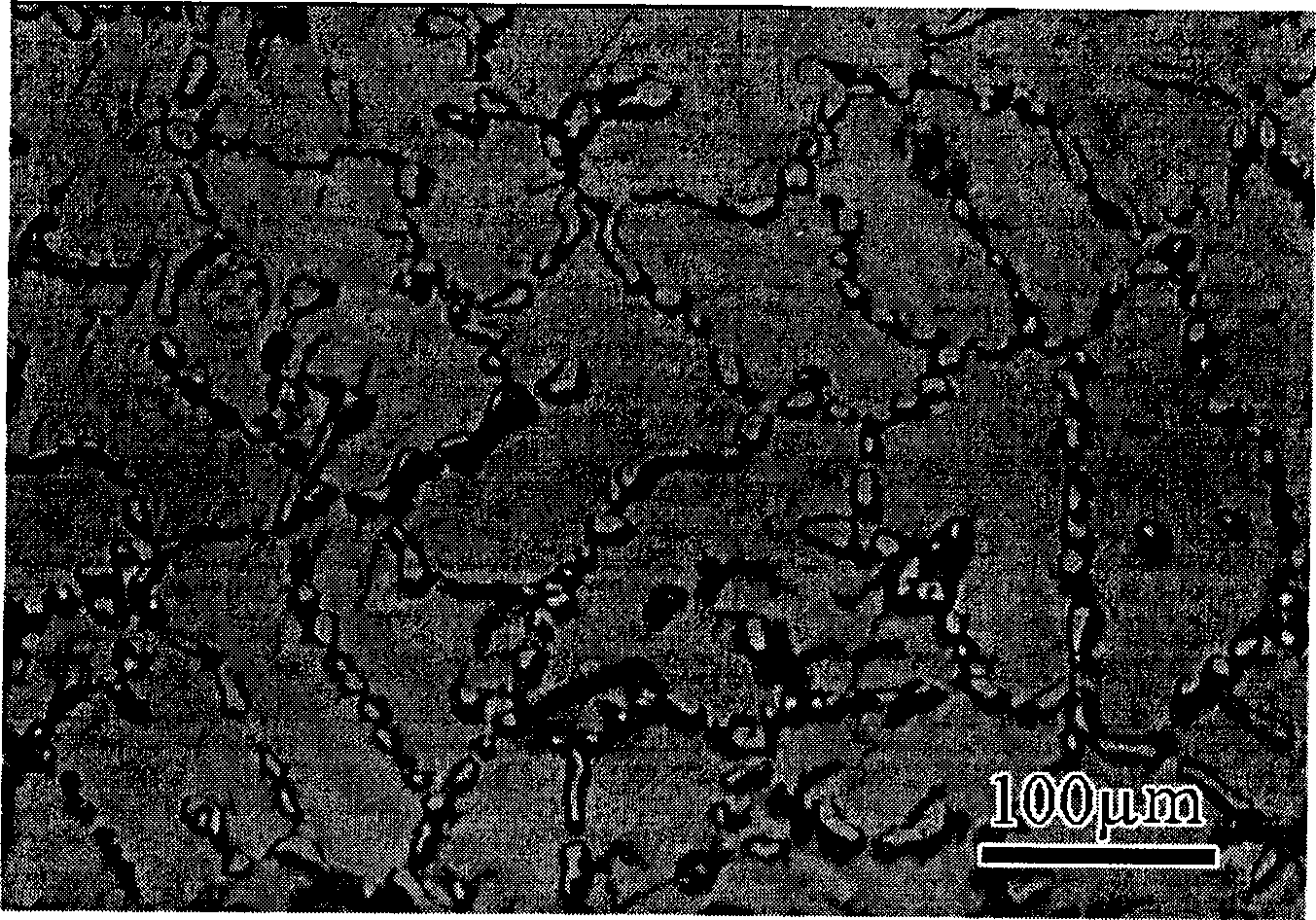

[0026] Put the bulk Ti-8Si (at%) hypoeutectic cast alloy into the resistance furnace, then the temperature in the resistance furnace chamber is raised from room temperature to 1100 °C at a rate of 5 °C per minute, and at 1100 °C After maintaining the temperature at ℃ for 120 minutes, turn off the power supply of the resistance furnace, and allow the alloy material to cool down to room temperature with the furnace. Ti in microstructure of alloy after treatment 5 Si 3 The phase transition becomes nearly equiaxed, the average grain diameter is refined to 5-10 μm, and the metallographic photo of the microstructure is shown in image 3 . The hardness of the alloy was tested with HV-3 Vickers hardness tester. Under the same test conditions, the hardness of the treated alloy was 141HV higher than that of the as-cast alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com