Substrate for flexible organic optoelectronic device and preparation method thereof

A technology of optoelectronic devices and substrates, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of poor adhesion between thin films and substrates, reduce production costs and process difficulties, improve performance and life, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

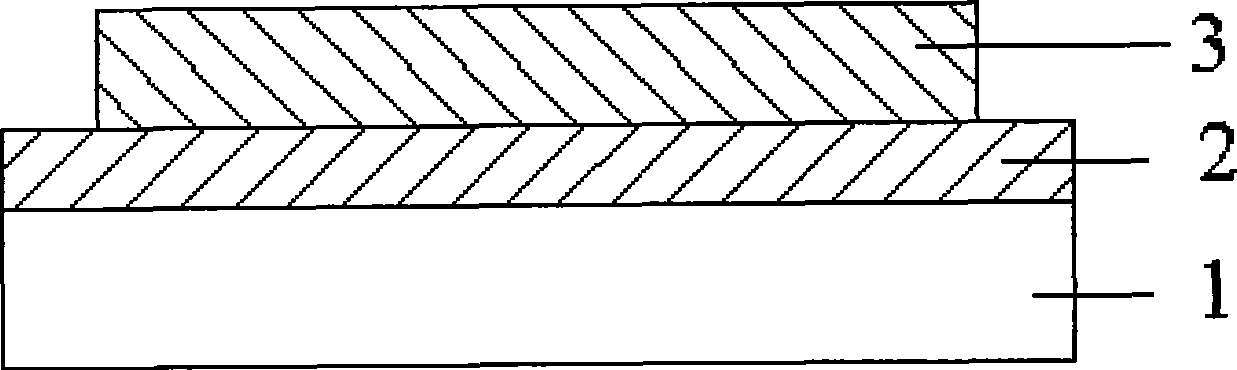

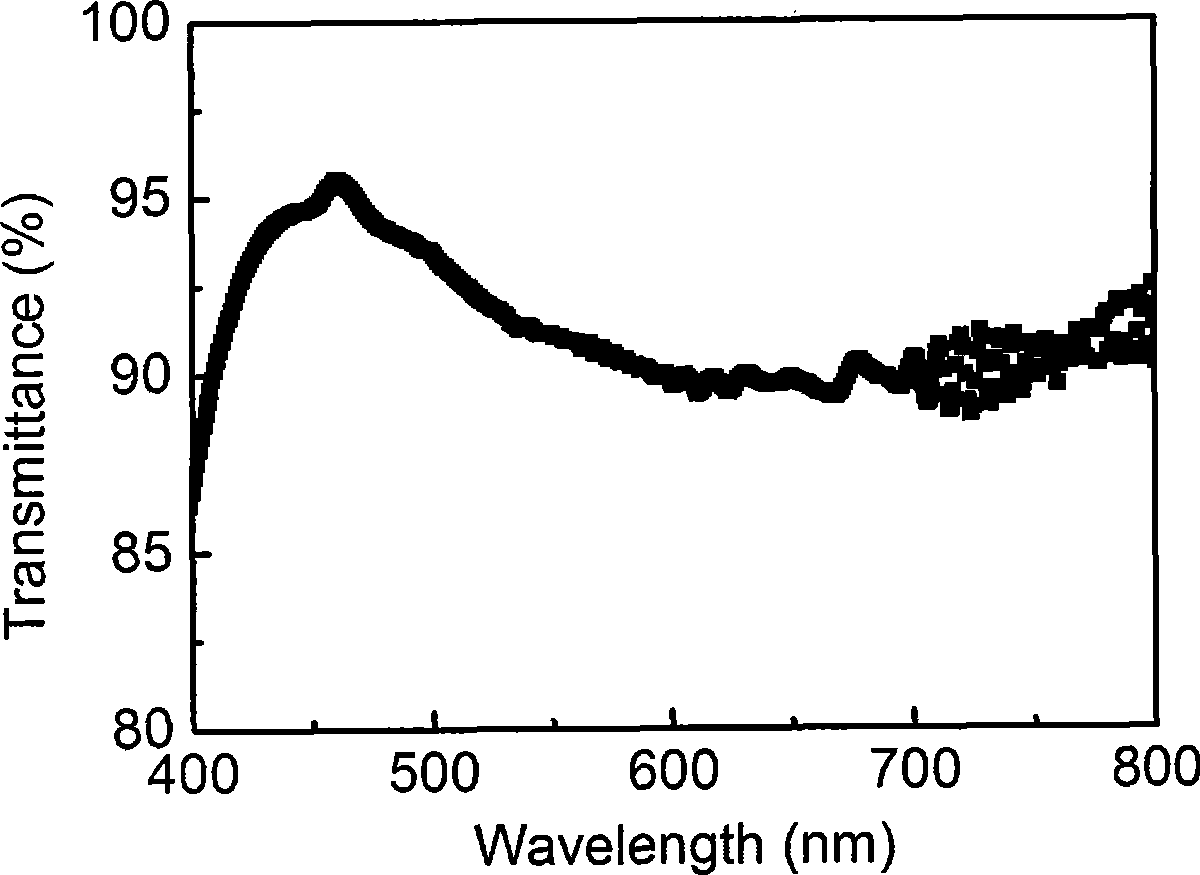

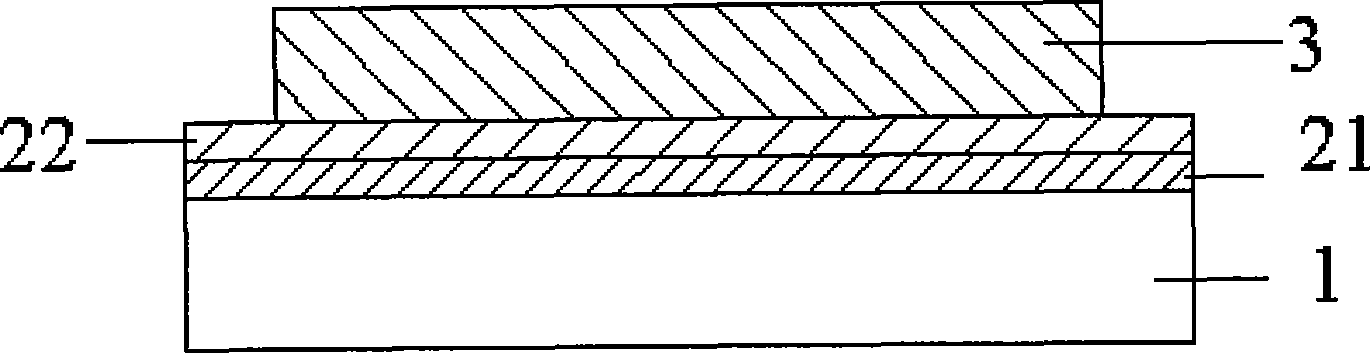

[0086] Such as figure 1 In the substrate structure shown, the flexible substrate 1 is a flexible polyethylene terephthalate polymer (PET) substrate, the adhesive layer 2 is a single-layer dual-curing system, and the conductive film 3 is ITO sputtered by DC magnetron. Transparent conductive film. The transmittance test curve is as figure 2 shown.

[0087] The preparation method is as follows:

[0088] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the PET substrate, and dry it with dry nitrogen after cleaning;

[0089] ② Mechanically stir the UV-curable silicone adhesive raw material diluted 1:10 with ethanol for 20 hours, then spin-coat it on the PET surface at a speed of 2000 rpm for one minute, and the film thickness is about 100 nanometers.

[0090] Wherein the ratio of adhesive raw material components is:

[0091] Silicone 94%

[0092] Photoinitiator 2.5%

[0093] Diluents and additives 3.5%;

[0094] ③UV curing trea...

Embodiment 2

[0099] Such as figure 1 In the substrate structure shown, the flexible substrate 1 is made of a flexible metal foil, the adhesive layer 2 is made of a single-layer UV-curable adhesive, and the conductive film 3 is a DC magnetron sputtered ITO transparent conductive film.

[0100] The preparation method is as follows:

[0101] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the flexible metal foil, and dry it with dry nitrogen after cleaning;

[0102] ② Mechanically stir the UV-curable silicone adhesive raw material diluted 1:1 with ethanol for 30 hours, then spin-coat it on the surface of the flexible metal foil at a speed of 3000 rpm for 1 minute, and the film thickness is about 200 nanometers;

[0103] Wherein the ratio of adhesive raw material components is:

[0104] Silicone 93%

[0105] Photoinitiator 4%

[0106] Diluents and additives 3%;

[0107] ③UV curing treatment on the surface of the substrate for 30 seconds;

[...

Embodiment 3

[0111] Such as figure 1 In the substrate structure shown, the flexible substrate 1 is a PET substrate, the adhesive layer 2 is a single-layer ultraviolet curing adhesive, and the conductive film 3 is a metal conductive film prepared by thermal evaporation.

[0112] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the surface of the PET substrate, and dry it with dry nitrogen after cleaning;

[0113] ② Mechanically stir the UV-curable silicone adhesive raw material diluted 1:10 with ethanol for 20 hours, then spin-coat it on the PET surface at a speed of 2000 rpm for one minute, and the film thickness is about 100 nanometers;

[0114] ③Irradiate the surface of the substrate with ultraviolet light for 30 seconds;

[0115] ④Put the substrate into a vacuum chamber, and evaporate a 100nm thick metal conductive film on the surface of the PET substrate by thermal evaporation at room temperature;

[0116] ⑤After taking the substrate out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com