Preparation of titanium dioxide nano-rod

A titanium dioxide and nanorod technology, applied in the directions of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of short reaction time, uneven length of titanium dioxide nanomaterials, long reaction time, etc. The effect of high absorbance, length-to-diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of titanium dioxide nanorods provided by the present invention, wherein, the method comprises heating the mixture containing titanium dioxide nanoparticles, alkali metal hydroxides and organic solvents to 80-120°C and then contacting with a surfactant, said titanium dioxide nanorods containing The time interval between the start of heating the mixture of particles, alkali metal hydroxide and organic solvent to 80°C and the start of contacting the mixture containing titanium dioxide nanoparticles, alkali metal hydroxide and organic solvent with the surfactant does not exceed 5 minutes, the organic solvent is an organic solvent with a boiling point not higher than 85°C and capable of dissolving the alkali metal hydroxide, and the heating method is microwave heating.

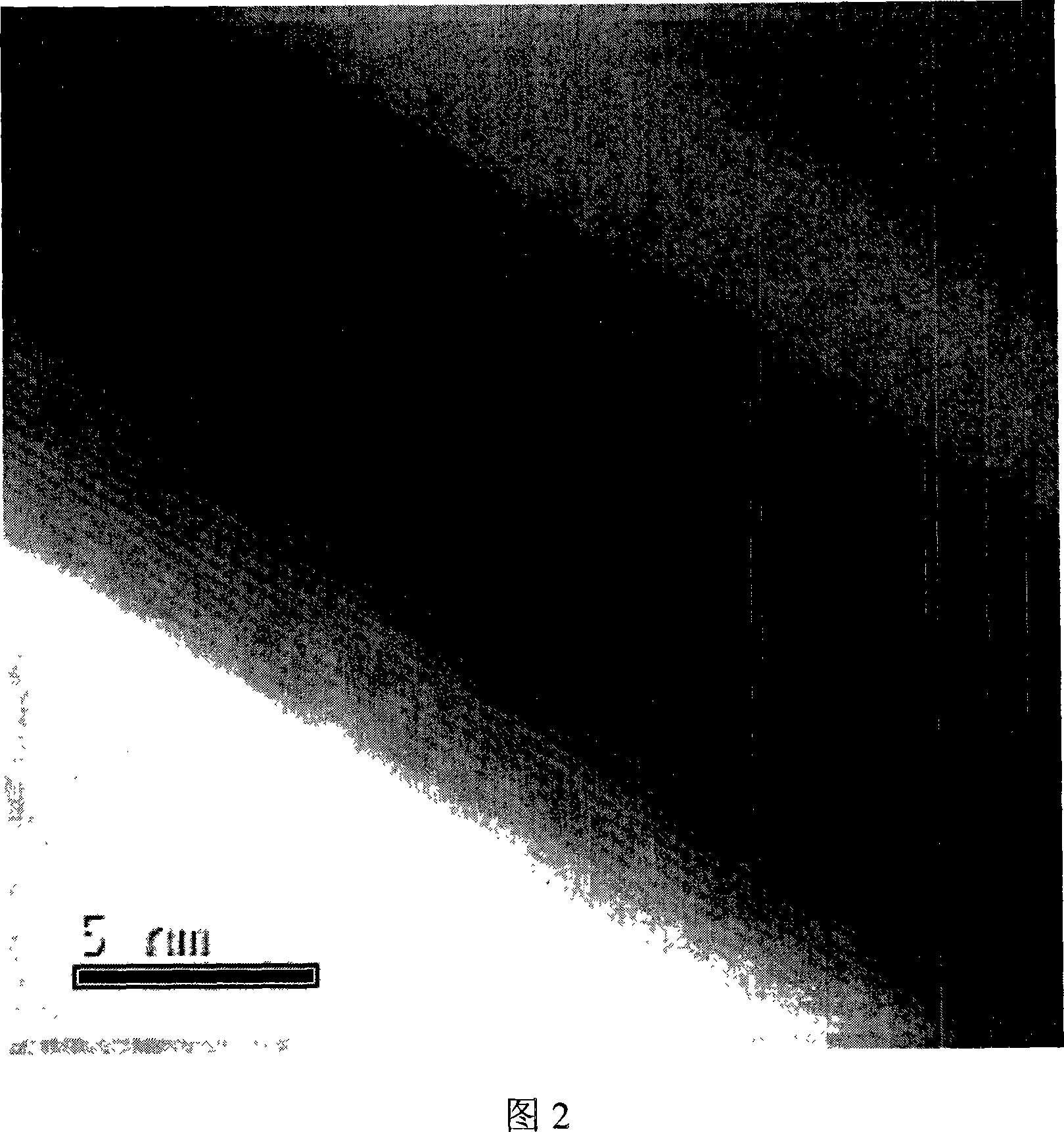

[0015] In a strong alkaline solution, titanium dioxide nanocrystals dissociate and fall off along their crystal planes to form nanochips. At a temperature of about 80 °C, the nanochips...

Embodiment 1

[0025] This example is used to illustrate the preparation method of the titanium dioxide nanorods of the present invention.

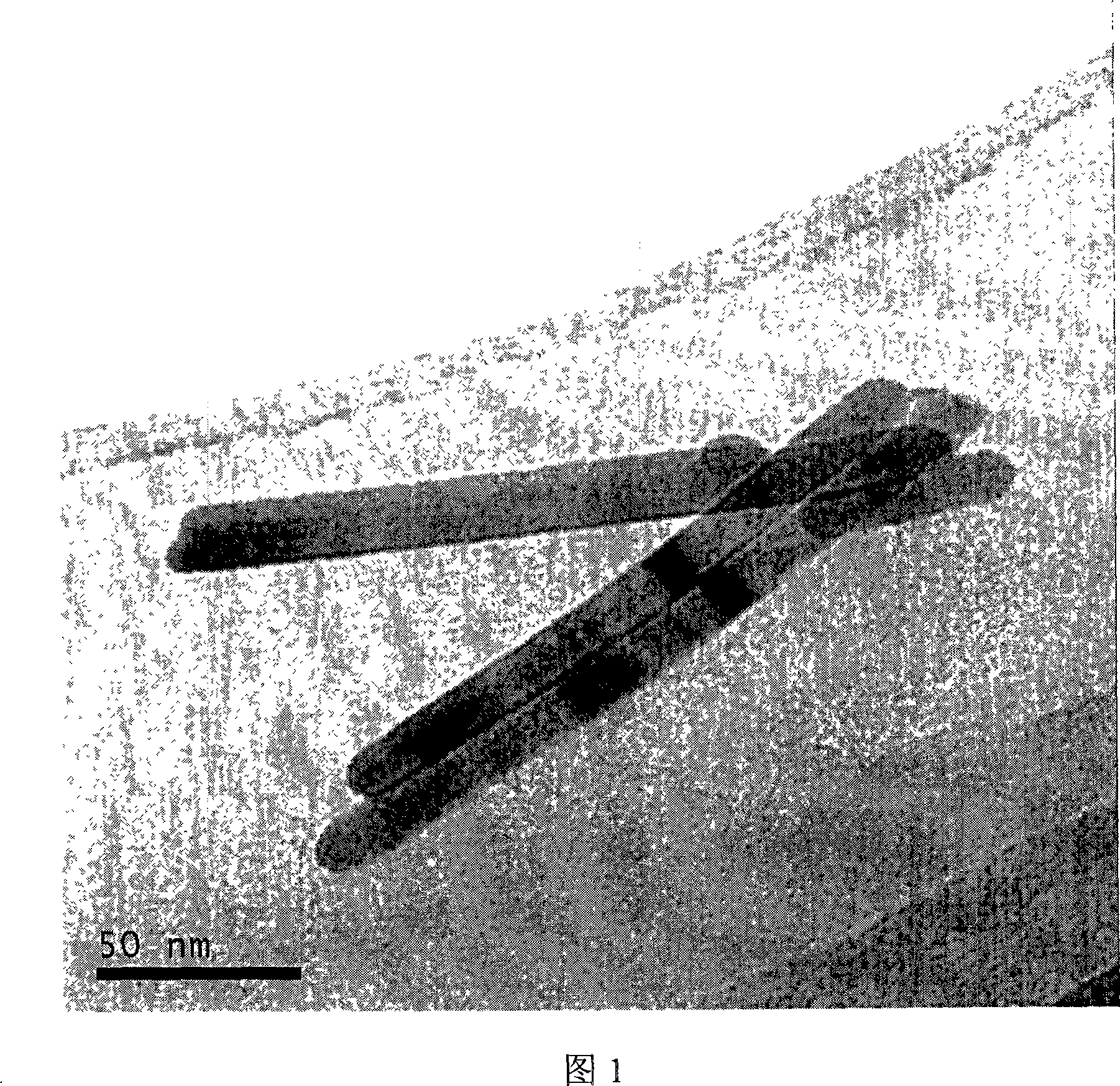

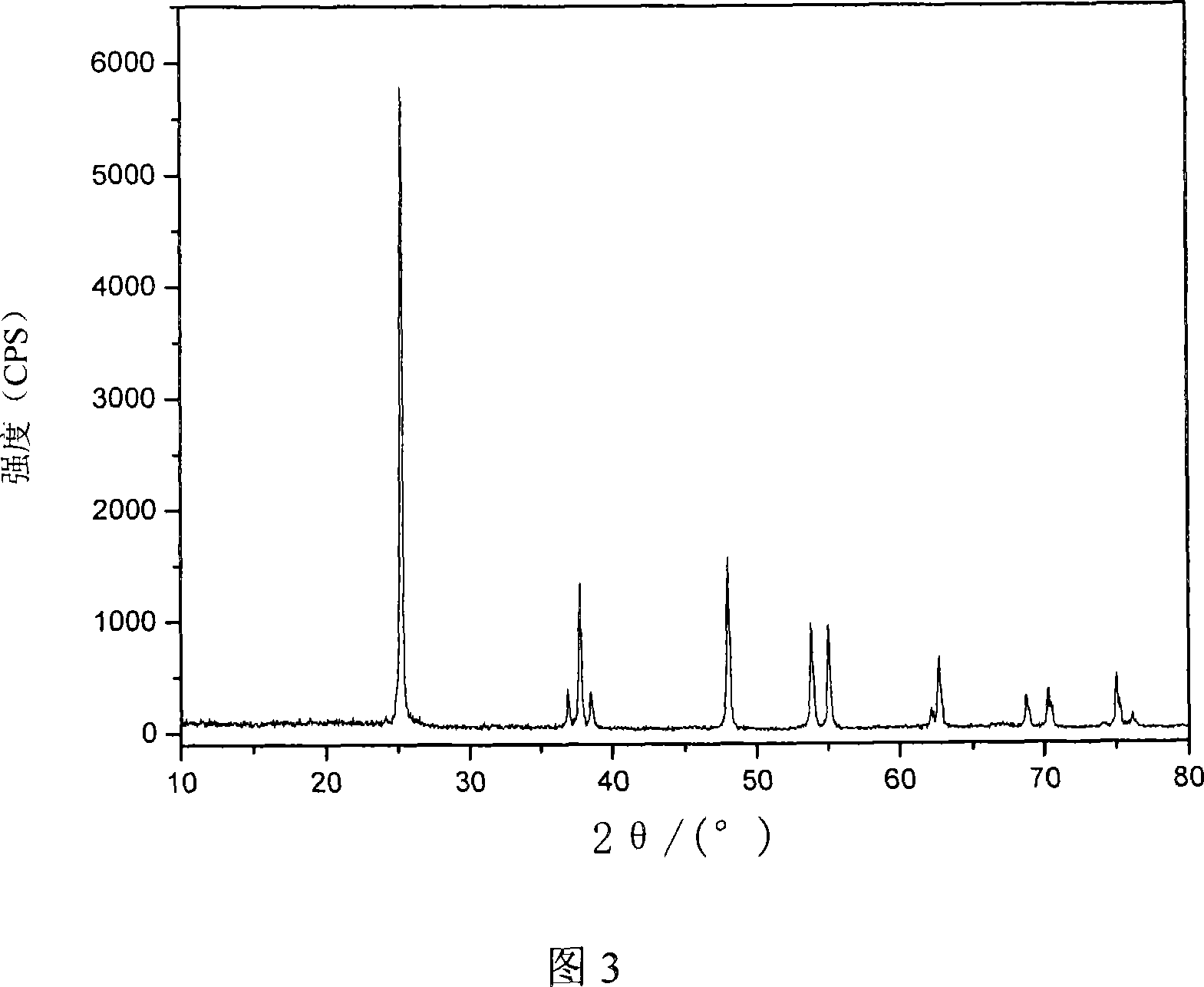

[0026]Add 5 grams of anatase-type titanium dioxide nanoparticles with a particle diameter of 30 nm to 50 ml of sodium hydroxide ethanol solution with a concentration of 10 mol / liter, and use an ultrasonic instrument to sonicate the titanium dioxide nanoparticles to disperse evenly. Put the whole system into a microwave reactor, adjust the microwave wavelength to 123 mm, and when the temperature of the solution rises to 90 ° C, under the condition of rapid stirring, add 3 ml of oleic acid dropwise at a constant speed, and the dropwise addition is completed within 3 minutes. Wherein, it takes about 0.5 minutes for the temperature of the solution to rise from 80°C to about 90°C. After the dropwise addition was completed, the reaction was continued at 90° C. for 60 minutes. After the reaction, the reaction solution was left to stand at 20°C for 2 hours, fi...

Embodiment 2

[0028] This example is used to illustrate the preparation method of the titanium dioxide nanorods of the present invention.

[0029] Carry out according to the method for embodiment 1, difference is, the sodium hydroxide ethanolic solution of 10 mol / liter replaces with the potassium hydroxide carbon tetrachloride solution of 8 mol / liter, and the consumption of potassium hydroxide carbon tetrachloride solution is 60 milliliters; the particle diameter of titanium dioxide nanoparticles is 10 nanometers, and its dosage is 5 grams; the microwave wavelength is 100 millimeters, the reaction temperature is 80° C., and the reaction time is 80 minutes. Oleic acid was replaced by cetyltrimethylammonium bromide in a volume of 5 ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com