Production method of N-acetyl-L-glutamine

A technology of glutamine and production method, applied in the production field of L-type amino acid N-acetylation reaction, can solve problems such as large-scale production without manufacturers, and achieve the effects of simple process, wide source of raw materials, and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

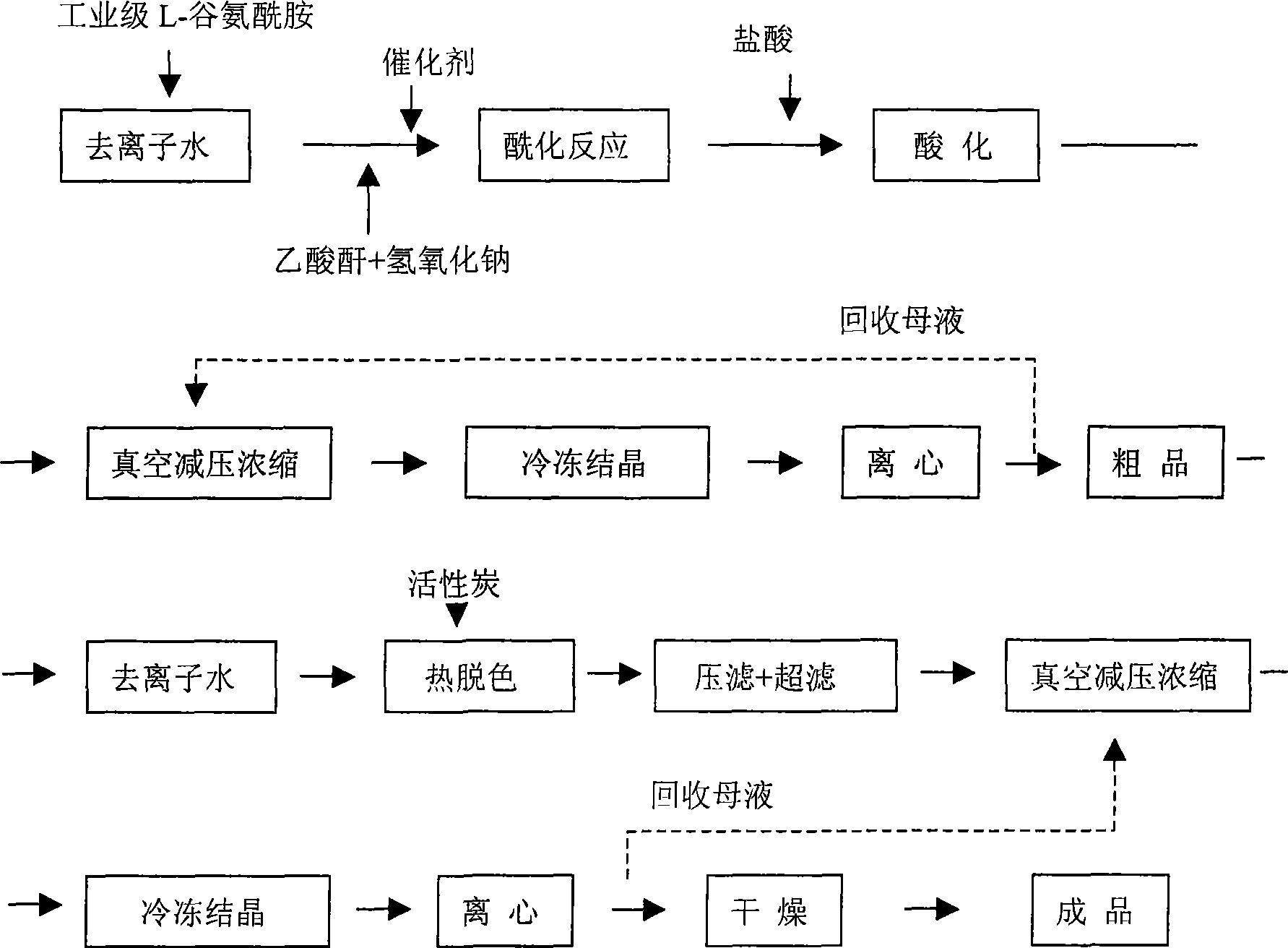

Method used

Image

Examples

Embodiment 1

[0025] Mix L-glutamine and water at a weight ratio of 1:5, add 0.03% sodium sulfite by weight of raw materials, and simultaneously add acetic anhydride dropwise to control pH7, acylate at 78°C for 1 hour, and add 6N hydrochloric acid dropwise after the acylation is complete Adjust the pH to 0.5, concentrate until crystals are precipitated, stop the concentration, stir, freeze and crystallize to 2°C, centrifuge, and dry to obtain the crude product. Dissolve the crude product in deionized water with a mass ratio of 3 times, add 3% activated carbon for decolorization, and then obtain the finished product after filtration, concentration, crystallization, centrifugation and drying. The yield can reach 92% and the purity is 99.5%.

Embodiment 2

[0027] Mix L-glutamine and water at a weight ratio of 1:1, add 0.01% sodium bisulfite by weight of raw materials, and at the same time add 40% sodium hydroxide dropwise to control pH 12, acylate at 40°C for 1.5h, until acylation After completion, add 6N hydrochloric acid dropwise to adjust the pH to 3.0, concentrate until crystals are precipitated, stop the concentration, stir, freeze and crystallize to 10°C, centrifuge, and dry to obtain a crude product. Dissolve the crude product in deionized water with a mass ratio of 7 times, add 5% activated carbon for decolorization, and then obtain the finished product after filtration, concentration, crystallization, centrifugation and drying. The yield can reach 95% and the purity is 99.25%.

Embodiment 3

[0029] Mix L-glutamine and water at a weight ratio of 1:10, add 0.05% sodium thiosulfate by weight of raw materials, and at the same time add 35% sodium hydroxide dropwise to control pH9, acylate at 5°C for 3 hours until the acylation is complete Finally, add 6N hydrochloric acid dropwise to adjust the pH to 2.0, concentrate until crystals are precipitated, stop the concentration, stir and freeze to crystallize to 5°C, centrifuge and dry to obtain the crude product. Dissolve the crude product in deionized water with a mass ratio of 5 times, add 4% activated carbon for decolorization, and then obtain the finished product after filtration, concentration, crystallization, centrifugation and drying. The yield can reach 92% and the purity is 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com