Process for preparing attapulgite based composite material

A composite material, attapulgite technology, applied in the direction of fibrous filler, dyed organosilicon compound treatment, etc., can solve problems such as poor compatibility, and achieve the effect of simple preparation process and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 400mL beaker, 5.0g of attapulgite raw soil was dispersed in 200mL of deionized water, and ultrasonically treated at 40°C with a power of 40KHz for 8h. Take the supernatant, centrifuge, and weigh about 2.0 g of the obtained solid matter after drying. Grind and disperse the obtained solid substance in 50 mL of 2.0 mol / L aqueous hydrochloric acid solution, soak in the hydrochloric acid solution for about 4 hours, wash repeatedly with deionized water until the filtrate is neutral, and vacuum dry at 40°C for 72 hours to obtain Fibrous attapulgite with more hydroxyl groups on the surface.

[0034] The purified attapulgite was ultrasonically dispersed in toluene, an appropriate amount of aminopropyltriethoxysilane was added thereto, and the attapulgite was treated at 60° C. for 2 hours to obtain a surface-aminated attapulgite.

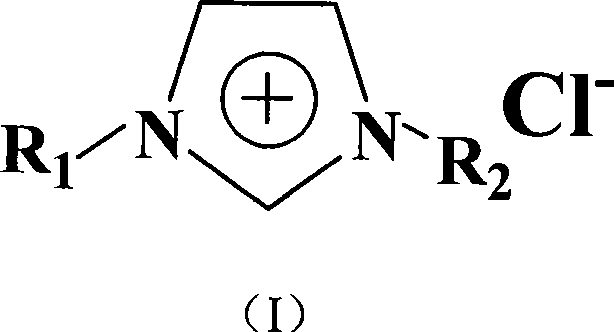

[0035] The surface aminated attapulgite and the ionic liquid 1-carboxyethyl-3-butylimidazolium chloride containing carboxyl functional group wer...

Embodiment 2

[0038]Using the same method as in Example 1, the surface aminated fibrous attapulgite was obtained.

[0039] The surface aminated attapulgite and the ionic liquid 1-carboxypropyl-3-hexylimidazolium chloride containing carboxyl functional group were ultrasonically dispersed in n-hexane, and stirred and reacted at 60° C. for 2 h. After the solvent is removed by centrifugation, the product is washed with a large amount of ethanol to remove unreacted ionic liquid, and vacuum-dried at 40-100° C. to obtain an attapulgite-based composite material whose surface is modified by a functionalized ionic liquid. The composite material is a hydrophilic material.

[0040] The attapulgite composite material modified by the functionalized ionic liquid whose anion is chloride ion is ultrasonically dispersed in water, and a sodium trifluoromethanesulfonate solution with a concentration of 1.0 mol / L is added to it, and the attapulgite / ionic liquid composite material is formed by hydrophilic Aqueo...

Embodiment 3

[0042] Using the same method as in Example 1, the surface aminated fibrous attapulgite was obtained.

[0043] The surface aminated attapulgite and the ionic liquid 1-carboxyethyl-3-octylimidazolium chloride containing carboxyl functional group were ultrasonically dispersed in n-hexane, and stirred and reacted at 60° C. for 2 h. After the solvent is removed by centrifugation, the product is washed with a large amount of ethanol to remove unreacted ionic liquid, and vacuum-dried at 40-100° C. to obtain an attapulgite-based composite material whose surface is modified by a functionalized ionic liquid. The composite material is a hydrophilic material.

[0044] The attapulgite composite material modified by the functionalized ionic liquid whose anion is chloride ion is ultrasonically dispersed in water, and a lithium bis(trifluoromethylsulfonyl)amide solution with a concentration of 0.5mol / L is added thereto, and the attapulgite / ionic liquid The composite material changes from hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com