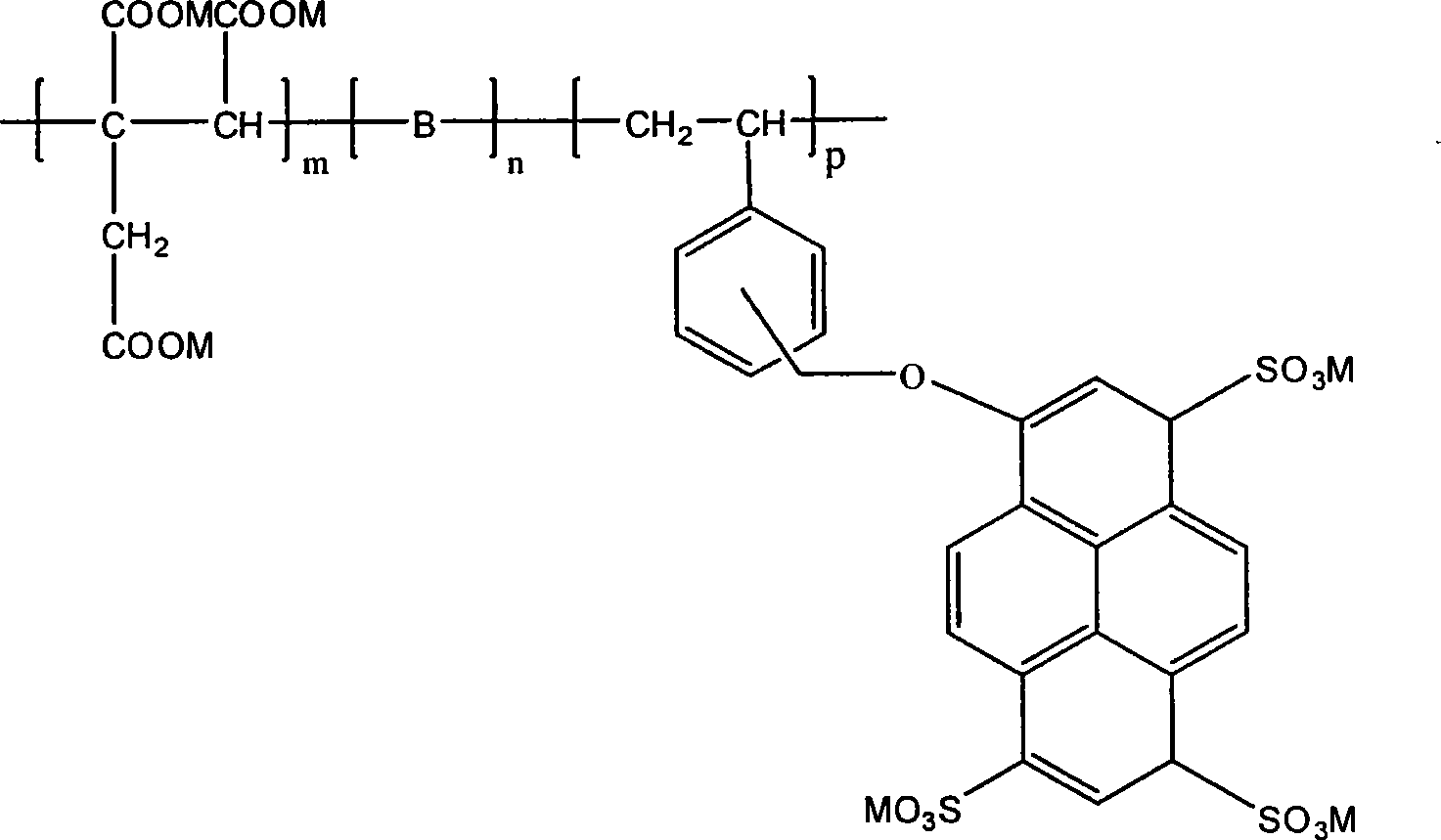

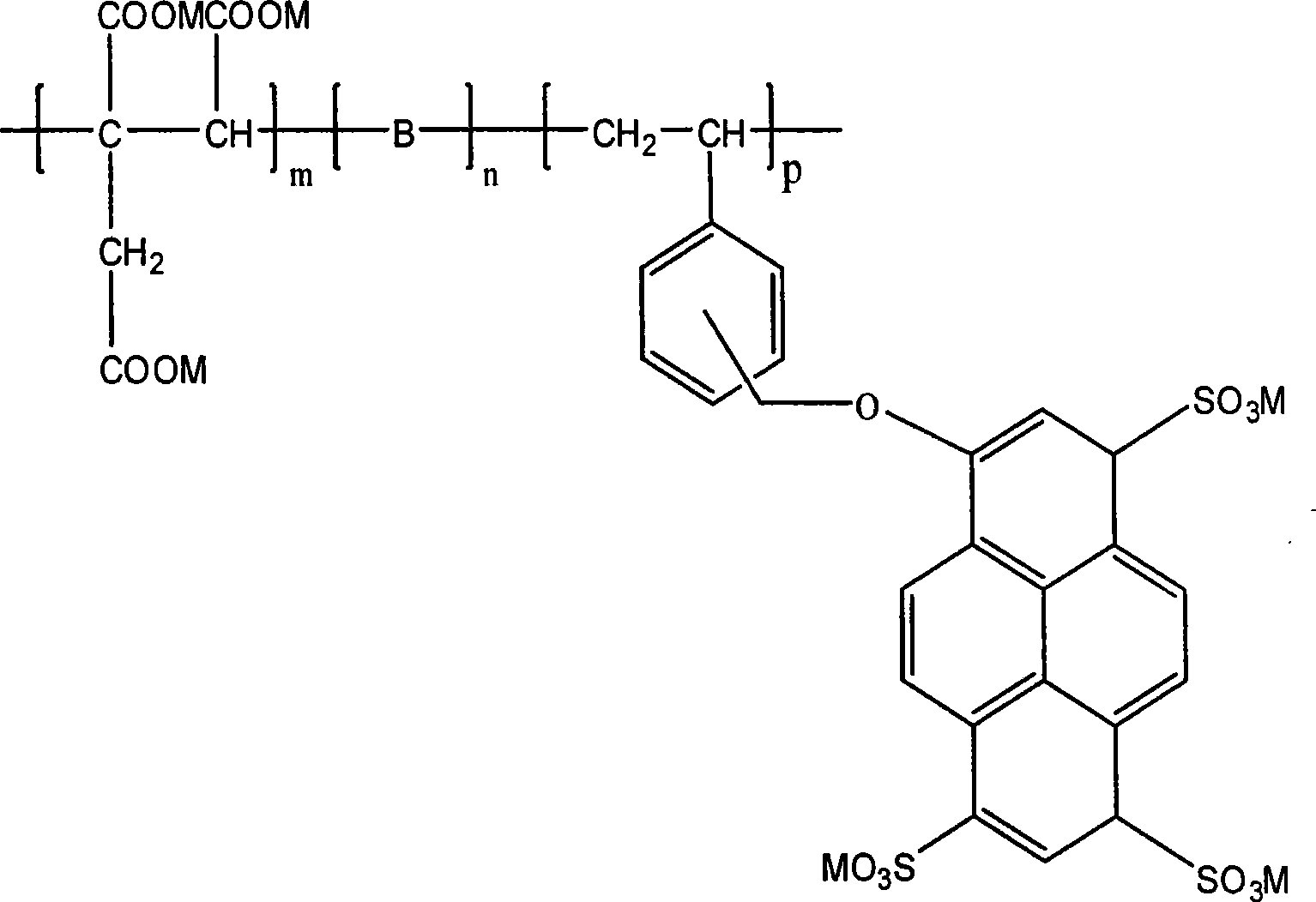

Fluorescent tracing scale inhibitor and preparation thereof

A fluorescent tracer and antiscalant technology, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Scale and, high-efficiency dispersion performance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: At room temperature, add 210.0 g of citric acid monohydrate into a four-neck flask equipped with a stirring device and a reflux condenser, then add 215 mL of sulfuric acid aqueous solution with a volume concentration of 60%, heat and stir, and react at 125 ° C for 7 h. Cool to 40°C, filter with suction to obtain a yellow solid, wash with glacial acetic acid three times, recrystallize twice with glacial acetic acid, and dry under vacuum at 50°C for 5 hours to obtain aconitic acid;

[0023] in N 2 Atmosphere and room temperature, add 13.1g 8-hydroxyl-1,3,6-sodium pyrenetrisulfonate, 5.0g vinylbenzyl chloride liquid, 3g 50wt% NaOH aqueous solution and 110mL dimethyl sulfoxide to the four-necked flask, Stir at room temperature for 6 hours, filter, and distill the filtrate under reduced pressure at 50°C to remove dimethyl sulfoxide, add 150 mL of acetone, filter to obtain a yellow solid, and dry it in vacuum at 50°C for 48 hours to obtain 8-(4-vinylbenzyloxy)-1. ...

Embodiment 2

[0026] Example 2: At room temperature, add 210.0 g of citric acid monohydrate into a four-necked bottle equipped with a stirring device and a reflux condenser, then add 150 mL of sulfuric acid aqueous solution with a volume concentration of 80%, heat and stir, and react at 130 ° C for 6 h. Cool to 50°C, filter with suction to obtain a yellow solid, wash with glacial acetic acid three times, recrystallize with glacial acetic acid three times, and dry under vacuum at 60°C for 6 hours to obtain aconitic acid;

[0027] in N2 Atmosphere and room temperature, add 13.1g 8-hydroxyl-1,3,6-sodium pyrenetrisulfonate, 6.5g vinylbenzyl chloride liquid, 3.5g 50wt% NaOH aqueous solution and 125mL dimethyl sulfoxide to the four-necked flask , stirred at room temperature for 5h, filtered, and the filtrate was distilled off under reduced pressure at 60°C to remove dimethyl sulfoxide, then added 180mL of acetone, filtered to obtain a yellow solid, and dried in vacuo at 40°C for 36h to obtain 8-(4...

Embodiment 3

[0030] Example 3: At room temperature, add 258.0 g of sodium citrate into a four-necked flask equipped with a stirring device and a reflux condenser, then add 250 mL of sulfuric acid aqueous solution with a volume concentration of 50%, heat and stir, react at 140 ° C for 5 h, and cool to Suction filtration at 30°C to obtain a yellow solid, which was washed twice with glacial acetic acid and recrystallized twice with acetic acid, and dried in vacuum at 40°C for 5 hours to obtain sodium aconitate;

[0031] in N 2 Atmosphere and room temperature, add 13.1g 8-hydroxyl-1,3,6-sodium pyrenetrisulfonate, 6.0g vinylbenzyl chloride liquid, 5.0g 50wt% NaOH aqueous solution and 150mL dimethyl sulfoxide to the four-necked flask , stirred at room temperature for 6h, filtered, and the filtrate was distilled off under reduced pressure at 50°C to remove dimethyl sulfoxide, then added 100mL of acetone, filtered to obtain a yellow solid, dried in vacuo at 60°C for 48h, and obtained 8-(4-vinylben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com