Method for preparing highly sulfonated sodium lignosulfonate

A technology of sodium lignosulfonate and high sulfonation degree, applied in the directions of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of harsh reaction conditions, limiting the industrial application of alkali lignin sulfonation modification, etc. , to achieve the effect of easy process control, improved utilization value and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 100g of wheatgrass alkali lignin, add 300g of distilled water, stir for 30 minutes, adjust the pH value of the solution to 3 with dilute sulfuric acid (10% Wt), and filter. Add 400g of 2.5wt% NaOH solution to the precipitate, heat to 50°C while stirring, dropwise add 50g of aqueous solution containing 5g of ammonium persulfate and 2g of ferrous sulfate, and slowly heat up to 65°C for free radical degradation reaction, and react for 10 minutes ; Under the state of stirring, drop 7g paraformaldehyde (polymerization degree 8~100, Shanghai Huishen Chemical Co., Ltd.), after fully stirring evenly, be placed in the frequency conversion microwave reactor, adjust the power to be 300W, control the temperature to be 70 °C, after reacting for 10 minutes, 50 g of an aqueous solution containing 20 g of sodium sulfite was added. The mixture was placed in a microwave reactor, the power was adjusted to 300W, the temperature was controlled to 85°C, and the reaction was carried out ...

Embodiment 2

[0027] Take 100g of wheatgrass alkali lignin, add 300g of distilled water, stir for 30 minutes, adjust the pH value of the solution to 3 with dilute sulfuric acid (10% Wt), and filter. Add 400g of 2.5wt% NaOH solution to the precipitate, heat to 50°C while stirring, add dropwise 50g of an aqueous solution containing 30g of ammonium persulfate and 5g of ferrous sulfate, and slowly heat up to 75°C for free radical degradation reaction, and keep warm for 30 minutes ; In the state of stirring, drop 12g paraformaldehyde (polymerization degree 8~100, Shanghai Huishen Chemical Co., Ltd.), after fully stirring evenly, place in the frequency conversion microwave reactor, adjust the power to be 300W, and control the temperature to be 85 After reacting for 15 minutes, 50 g of an aqueous solution containing 50 g of sodium sulfite was added. The mixture was placed in a microwave reactor, the power was adjusted to 800W, the temperature was controlled to 95°C, and the reaction was carried ou...

Embodiment 3

[0029] Take 100g of wheatgrass alkali lignin, add 300g of distilled water, stir for 30 minutes, adjust the pH value of the solution to 3 with dilute sulfuric acid (10% Wt), and filter. Add 400g of 2.5wt% NaOH solution to the precipitate, heat to 50°C while stirring, dropwise add 50g of an aqueous solution of 25g ammonium persulfate and 4g ferrous sulfate, and slowly heat up to 75°C for free radical degradation reaction, and keep warm for 50 minutes; In the state of stirring, add 15g of paraformaldehyde (polymerization degree 8-100, Shanghai Huishen Chemical Co., Ltd.) dropwise, after fully stirring evenly, place it in a frequency conversion microwave reactor, adjust the power to 300W, and control the temperature to 75°C After 10 minutes of reaction, 50 g of aqueous solution containing 40 g of sodium sulfite was added. The mixture was placed in a microwave reactor, the power was adjusted to 1000W, the temperature was controlled to 85°C, and the reaction was carried out for 2.0 ...

PUM

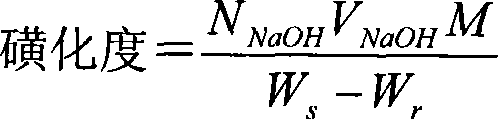

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com