Preparation method for calcium acetate magnesium salt

A technology of calcium and magnesium acetate and acetic acid, which is applied in the preparation of carboxylates, chemical instruments and methods, other chemical processes, etc., can solve the problems that waste liquid is not easy to reuse, and the cost of calcium and magnesium acetate is high, so as to save water and reduce Production cost and effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

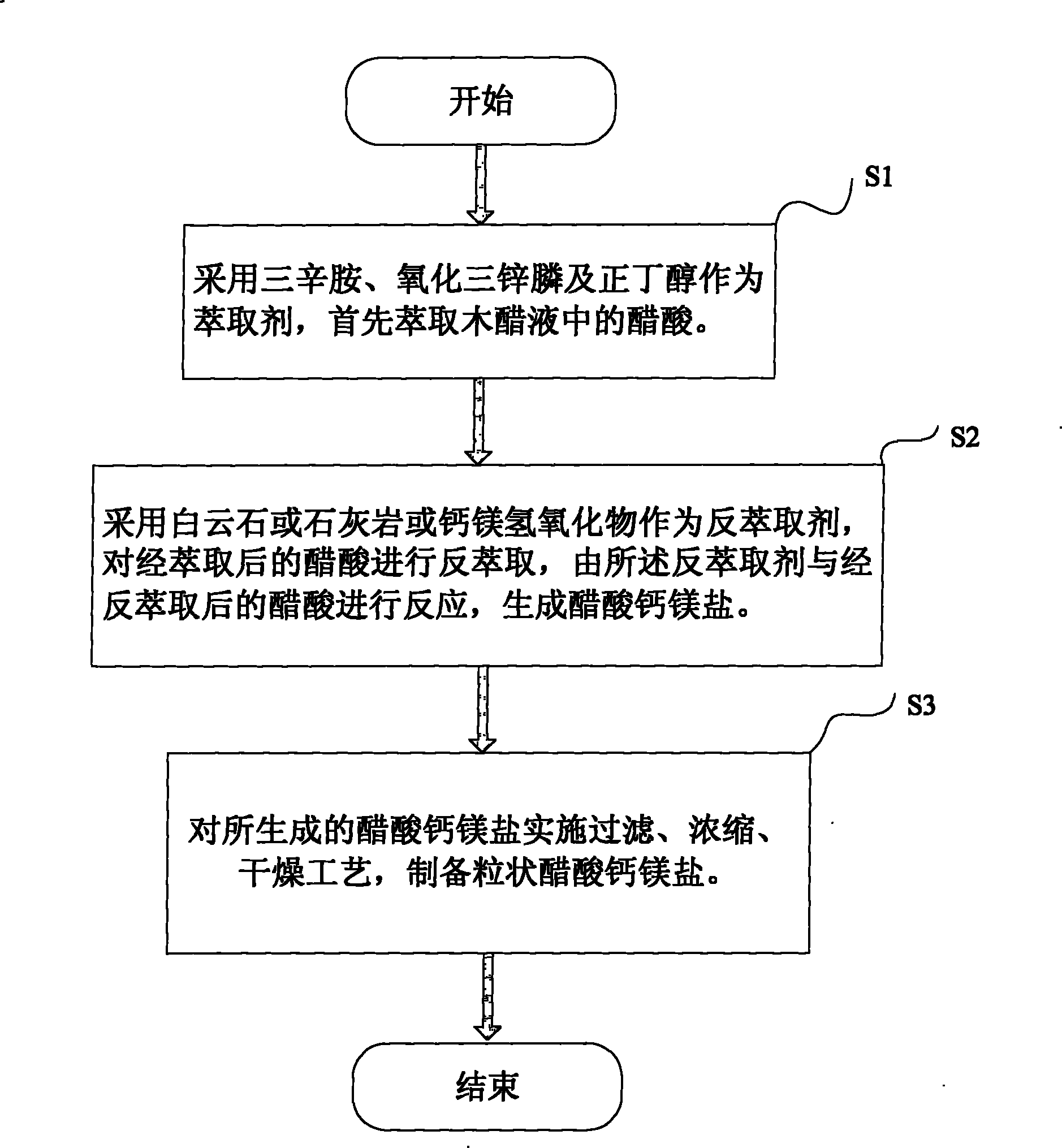

[0028] Such as figure 1 As shown, the present invention provides a kind of preparation method of calcium magnesium acetate: adopt organic solvent to extract wood vinegar liquid, then adopt dolomite (calcium magnesium oxide) or limestone (calcium magnesium carbonate) or calcium magnesium hydroxide back extraction The method for preparing calcium-magnesium acetate salt is to use acetic acid in wood vinegar and dolomite or limestone or calcium-magnesium hydroxide as raw materials to prepare calcium-magnesium acetate salt; wherein, the preparation method for calcium-magnesium acetate salt includes the following steps :

[0029] Extraction step S1: using trioctylamine, trioctylphosphine oxide and n-butanol as the extractant, using polyaluminum sulfate as the demulsifier, the dosage is 2%vol-6%vol of the total solution, and first extracting the acetic acid in the wood vinegar ;Then

[0030] Stripping step S2: using dolomite or limestone or calcium magnesium hydroxide as a strippin...

Embodiment 1

[0053] Embodiment 1: the preparation of calcium magnesium acetate

[0054] Get 500ml extractant at room temperature, the composition of extractant is mixed according to the ratio of trioctylamine (31%vol)+trioctylphosphine oxide (67%vol)+n-butanol (2%vol) and make, get 250ml wood vinegar Stir and mix with the extractant at room temperature for 20min at a stirring speed of 80-100r / min, then stand still, separate layers, and separate oil and water.

[0055] Get 7.3 grams of dolomite (calcium-magnesium oxide) (calcium-magnesium molar ratio is 2.9: 7.0) and be mixed with 50ml of milk of lime solution, join in the above-mentioned separated oil phase, react and stir for 20min at room temperature, stirring speed is 80- 100r / min. Then filter and dry to obtain the CMA product.

Embodiment 2

[0056] Embodiment 2: the preparation of calcium magnesium acetate

[0057] Get 500ml extractant at room temperature, the composition of extractant is mixed according to the ratio of trioctylamine (31%vol)+trioctylphosphine oxide (67%vol)+n-butanol (2%vol) and make, get 250ml wood vinegar Stir and mix with the extractant at room temperature for 20min at a stirring speed of 80-100r / min, then stand still, separate layers, and separate oil and water.

[0058] Get 8.78 grams of limestone (calcium-magnesium carbonate) (calcium-magnesium molar ratio is 2.9:7.0) and be mixed with concentration and be 50ml lime milk solution, join in the above-mentioned separated oily phase, react and stir 20min under room temperature, stirring speed is 80 -100r / min. Then filter and dry to obtain the CMA product.

[0059] The invention mainly adopts the operation technology of extraction and neutralization reaction stripping, the process route is simple, and the operation temperature is low. The cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com