Method for MA/RE mutual separation in high-level waste

A polymer and nitrate technology, applied in ion exchange, radioactive purification, ion exchange regeneration, etc., can solve problems such as poor acid resistance and radiation resistance, concerns about post-treatment cycle safety, chemical instability, etc., and achieve selective adsorption Strong, safe and effective treatment and disposal, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

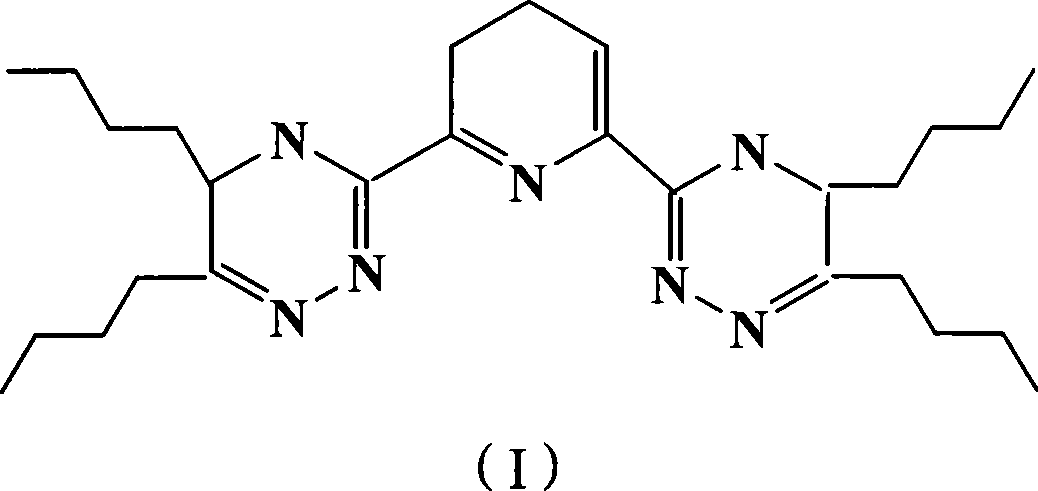

[0040] Experiment 1 Preparation of Adsorbent

[0041] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 1000 mL of dichloromethane and mix well; add 300 grams of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

[0042] Experiment 2 Preparation of Adsorbent

[0043] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 1500 mL of dichloromethane and mix well; add 600 grams of coating polymerization macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

[0044] Experiment 3 Preparation of Adsorbent

[0045] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 3000 mL of dichloromethane and mix we...

Embodiment 1

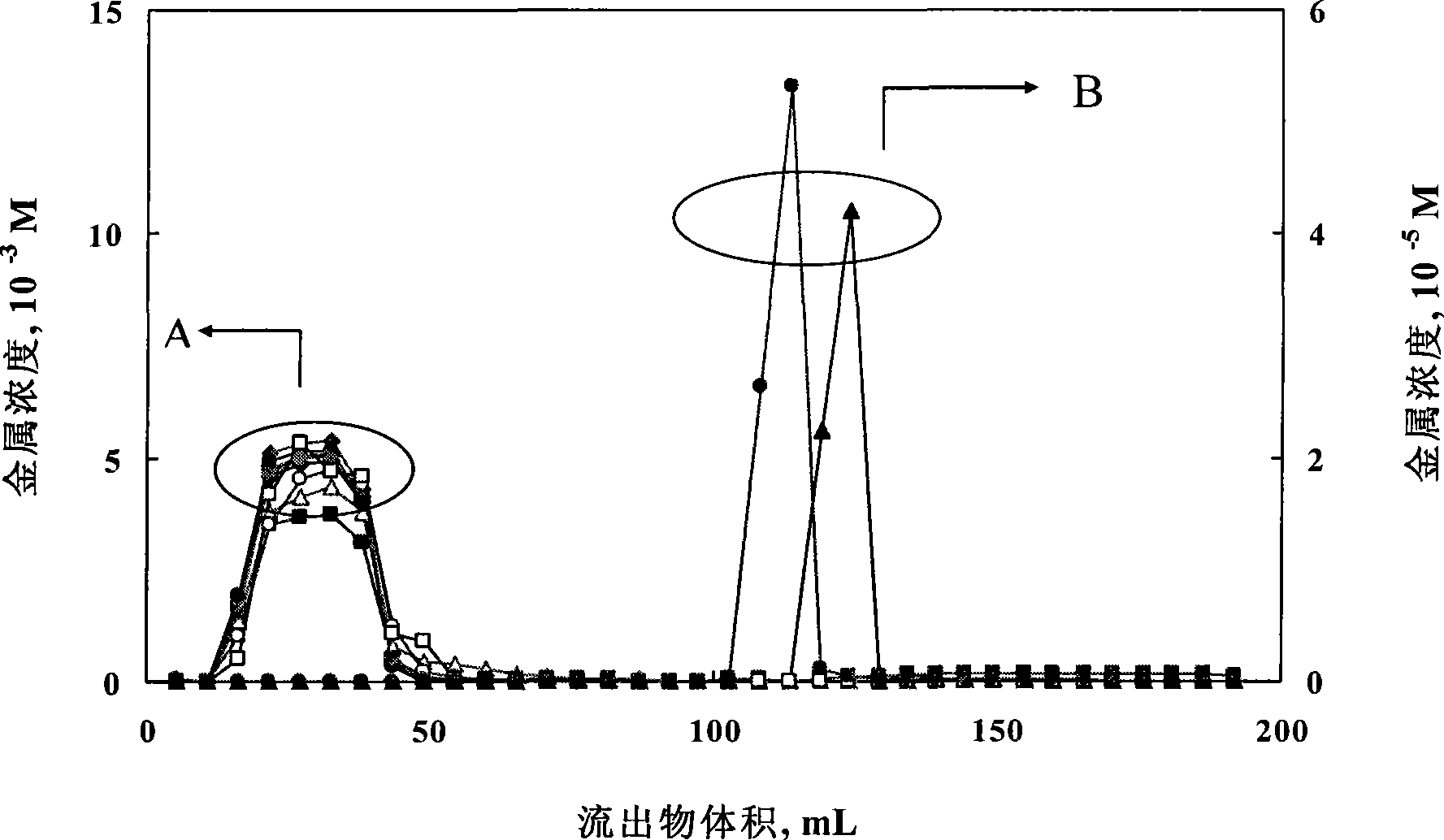

[0052] Example 1 Mutual separation of MA / RE in high-level radioactive waste (HLLW)

[0053] The adsorbent prepared in Experiment 1 was filled into a chromatographic separation column, and MA / RE in high-level radioactive waste (HLLW) were separated by liquid chromatography. The chromatographic column is a glass tube with an inner diameter of 1 cm and a height of 30 cm. The flow rate of the mobile phase is generally 1.0 ml / min and operated at room temperature.

[0054] HNO in the nitrate solution containing the minor actinides Am and Cm and rare earth elements was dissolved with concentrated nitric acid 3 The concentration is adjusted to 0.01 mol / liter, and the concentration of the rare earth element RE (the total concentration of the contained metal elements) in the system after adjustment is 5.0×10 -3 mol / L, the concentration of MA (the sum of Am and Cm) is 1.0×10 -5 mol / liter.

[0055] The nitrate solution after adjusting the concentration of nitric acid flows through the ...

Embodiment 2

[0060] Example 2 Mutual separation of MA / RE in high-level radioactive waste (HLLW)

[0061] Using the method of Example 1 to separate MA / RE from each other, the only difference is the NaNO in the eluent A 3 The molar concentration is 0.5mol / L; HNO 3 The molar concentration is 0.005mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com