Red long afterglow luminous material and preparing process thereof

A long afterglow luminescence, red technology, applied in the red long afterglow luminescent material and its preparation, the new red long afterglow luminescent material and its preparation field, can solve the problems of impure chromaticity, practical application is still far away, environmental pollution, etc. High energy transfer efficiency, high brightness, and the effect of improving crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material ratio:

[0024] Raw material name: Quality: Percentage of mass:

[0025] Gadolinium Oxide (Gd 2 O 3 ) 11.6545g 33.43%

[0026] Europium Oxide (Eu 2 O 3 ) 0.5955g 1.71%

[0027] Sulfur (S) 12.2500g 35.14%

[0028] Anhydrous sodium carbonate (Na 2 CO 3 ) 8.7475g 25.09%

[0029] Lithium carbonate (Li 2 CO 3 ) 1.4821g 4.25%

[0030] Titanium Dioxide (TiO 2 ) 0.1352g 0.39%

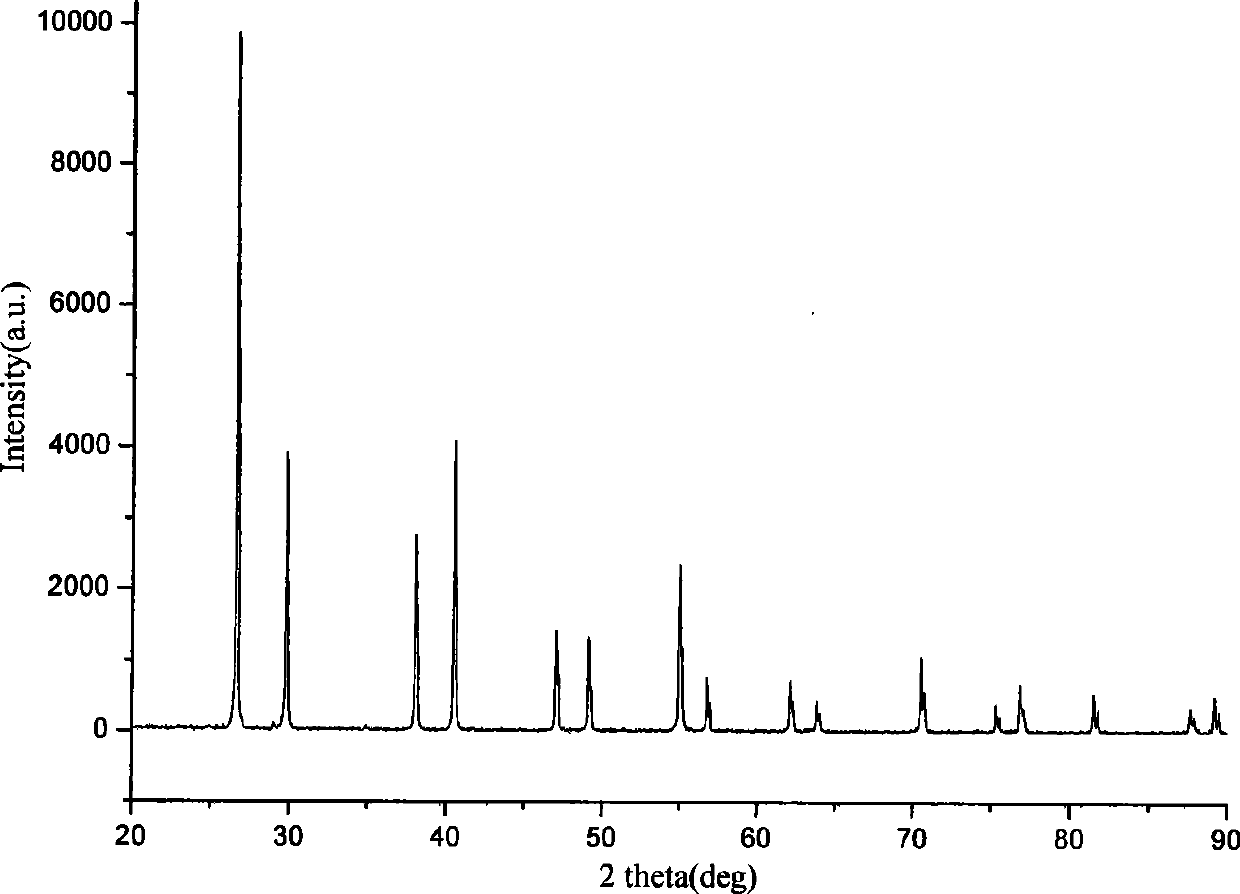

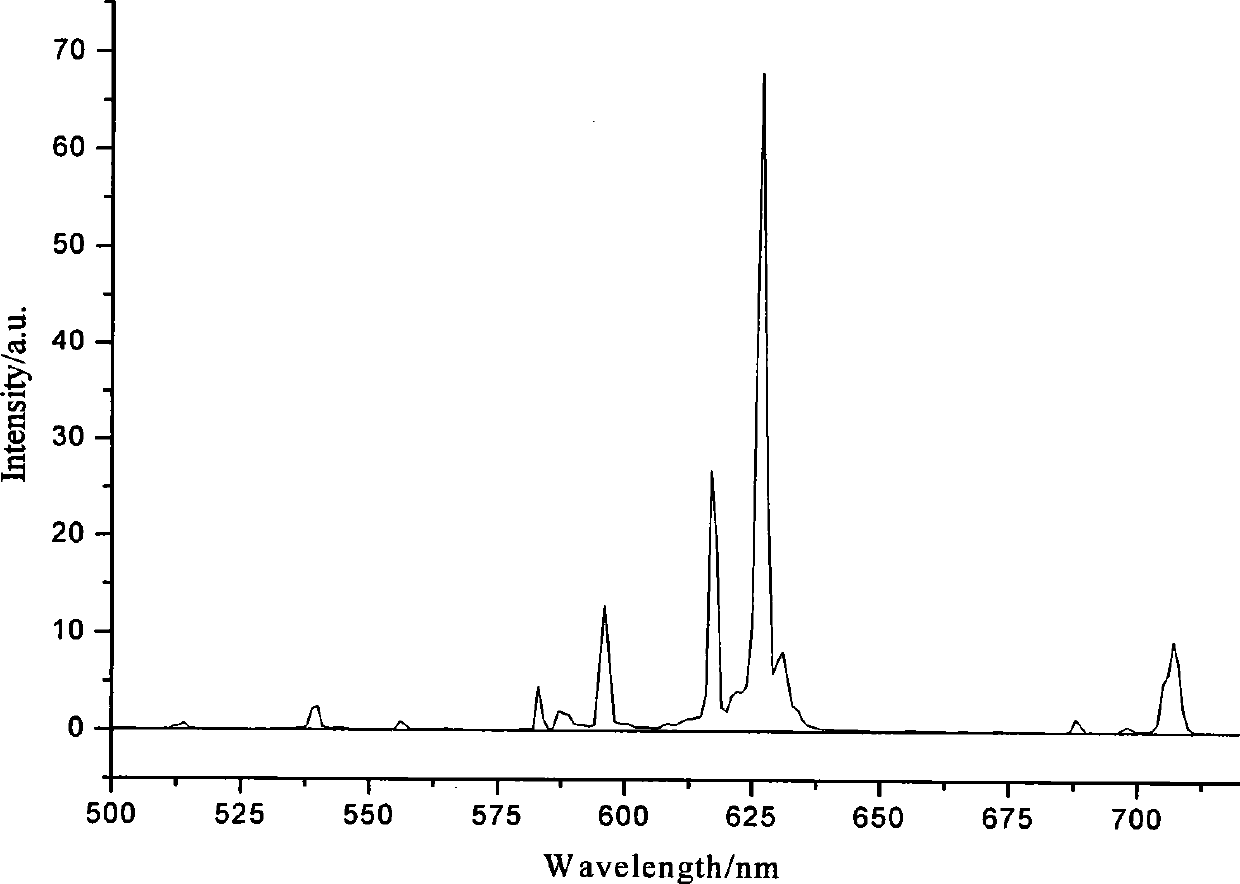

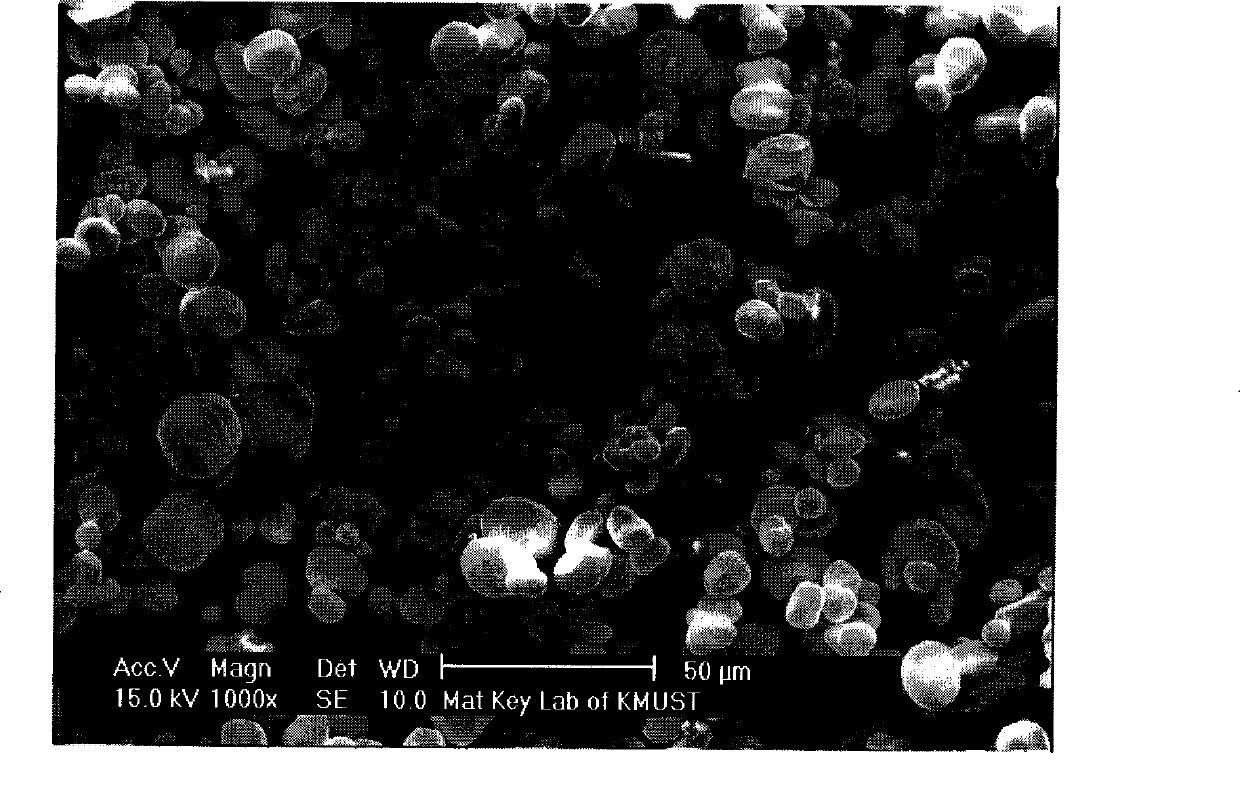

[0031] Fully grind and mix in an agate mortar, use a tablet press to press into pieces of appropriate size, put them in a corundum crucible, close the lid, heat in a high-temperature furnace, keep 350℃ for 20min, 1240℃ for 3.0h, After cooling to room temperature, the product is taken out of the oven, washed with deionized water, filtered, and dried in a constant temperature drying oven at 110°C for 3.0 hours to obtain a white powder sample Gd 2 O 2 S: Eu 3+ , Ti 4+ . After X-ray diffraction identification, as attached figure 1 As shown, the diffraction peak data of the prepared sample and Gd 2 ...

Embodiment 2

[0033] Raw material ratio:

[0034] Raw material name: Quality: Percentage of mass:

[0035] Gadolinium Oxide (Gd 2 O 3 ) 11.6545g 33.30%

[0036] Europium Oxide (Eu 2 O 3 ) 0.5955g 1.70%

[0037] Sulfur (S) 12.2500g 35.00%

[0038] Anhydrous sodium carbonate (Na 2 CO 3 ) 8.6319g 24.66%

[0039] Lithium carbonate (Li 2 CO 3 ) 1.4625g 4.18%

[0040] Magnesium oxide (MgO) 0.1352g 0.39%

[0041] Titanium Dioxide (TiO 2 ) 0.2704g 0.77%

[0042] Fully grind and mix in an agate mortar, use a tablet press to press into a suitable size tablet, put it in a small corundum crucible, cover it, and place it in a high-temperature furnace for heating, keep 300℃ for 30min, 1280℃ for 2.0 h, cooling to room temperature, the product is out of the oven, washed with deionized water, filtered, and dried in a constant temperature drying oven at 90°C for 5.0 hours to obtain a white powder sample Gd 2 O 2 S: Eu 3+ , Mg 2+ , Ti 4+ . After X-ray diffraction identification, the crystal structure of the produ...

Embodiment 3

[0044] Raw material ratio:

[0045] Raw material name: Quality: Percentage of mass:

[0046] Gadolinium Oxide (Gd 2 O 3 ) 11.6545g 33.30%

[0047] Europium Oxide (Eu2O 3 ) 0.5955g 1.70%

[0048] Sulfur (S) 12.2500g 35.00%

[0049] Anhydrous sodium carbonate (Na2CO 3 ) 8.5741g 24.50%

[0050] Lithium carbonate (Li 2 CO 3 ) 1.4527g 4.15%

[0051] Silica (SiO 2 ) 0.2028g 0.58%

[0052] Titanium Dioxide (TiO 2 ) 0.2704g 0.77%

[0053] Fully grind and mix in an agate mortar, use a tablet press to press into a piece of appropriate size, put it into a small corundum crucible, cover it, and place it in a high-temperature furnace for heating. Keep the temperature at 330°C for 25 minutes and hold at 1250°C for 2.5 h, cooling to room temperature, the product is out of the oven, washed with deionized water, filtered, and dried in a constant temperature drying oven at 100°C for 4.0 hours to obtain a white powder sample Gd 2 O 2 S: Eu 3+ , Si 4+ , Ti 4+ . After X-ray diffraction identification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com