Polyimide carbon fiber sizing agent and method for producing the same

A polyimide carbon fiber, setting agent technology, applied in the direction of carbon fiber, fiber processing, textiles and papermaking, etc., can solve the molecular structure preparation method of ES-T321 setting agent Unpublished, no published reports, molecular structure or preparation method No public reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

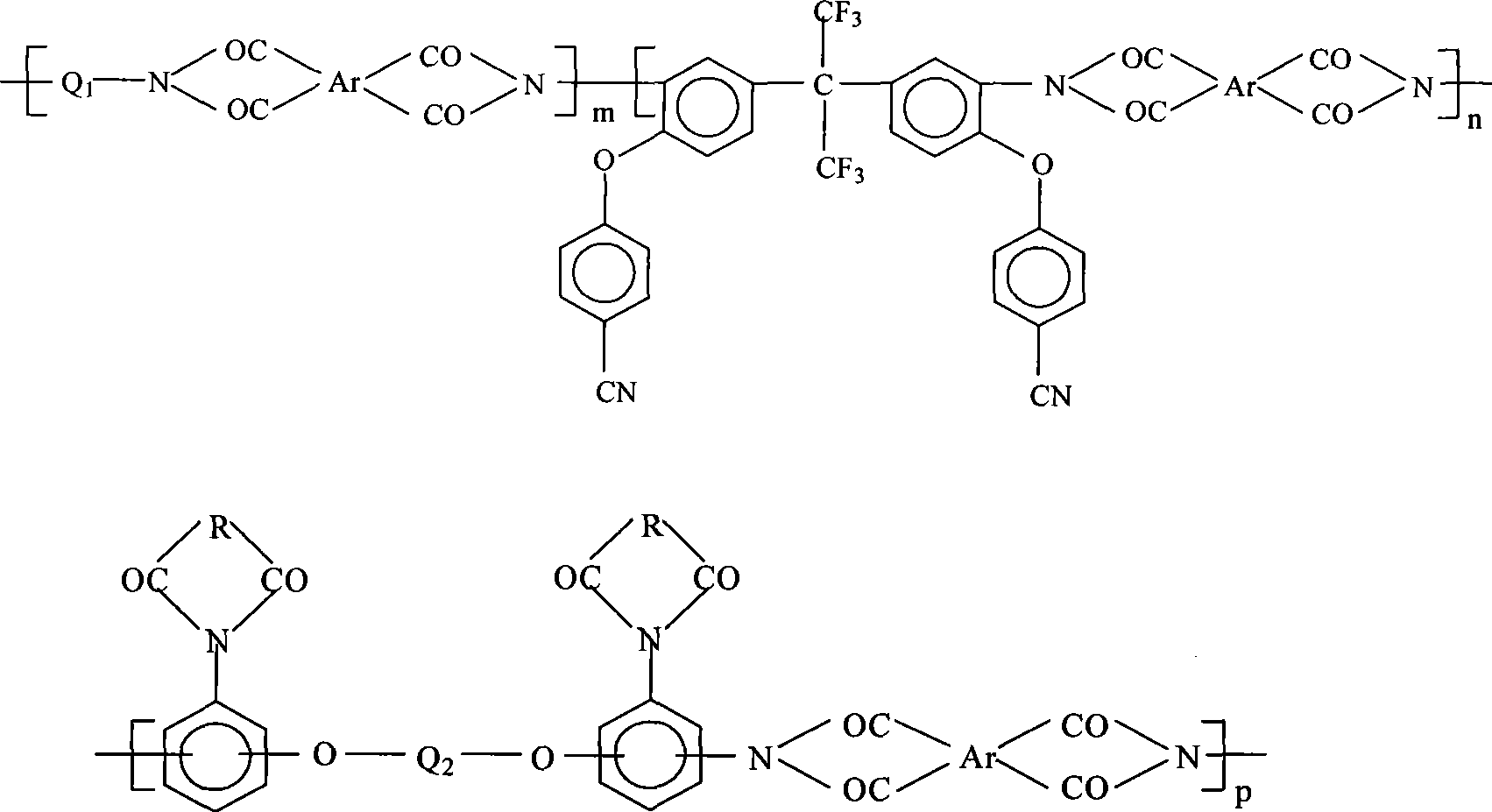

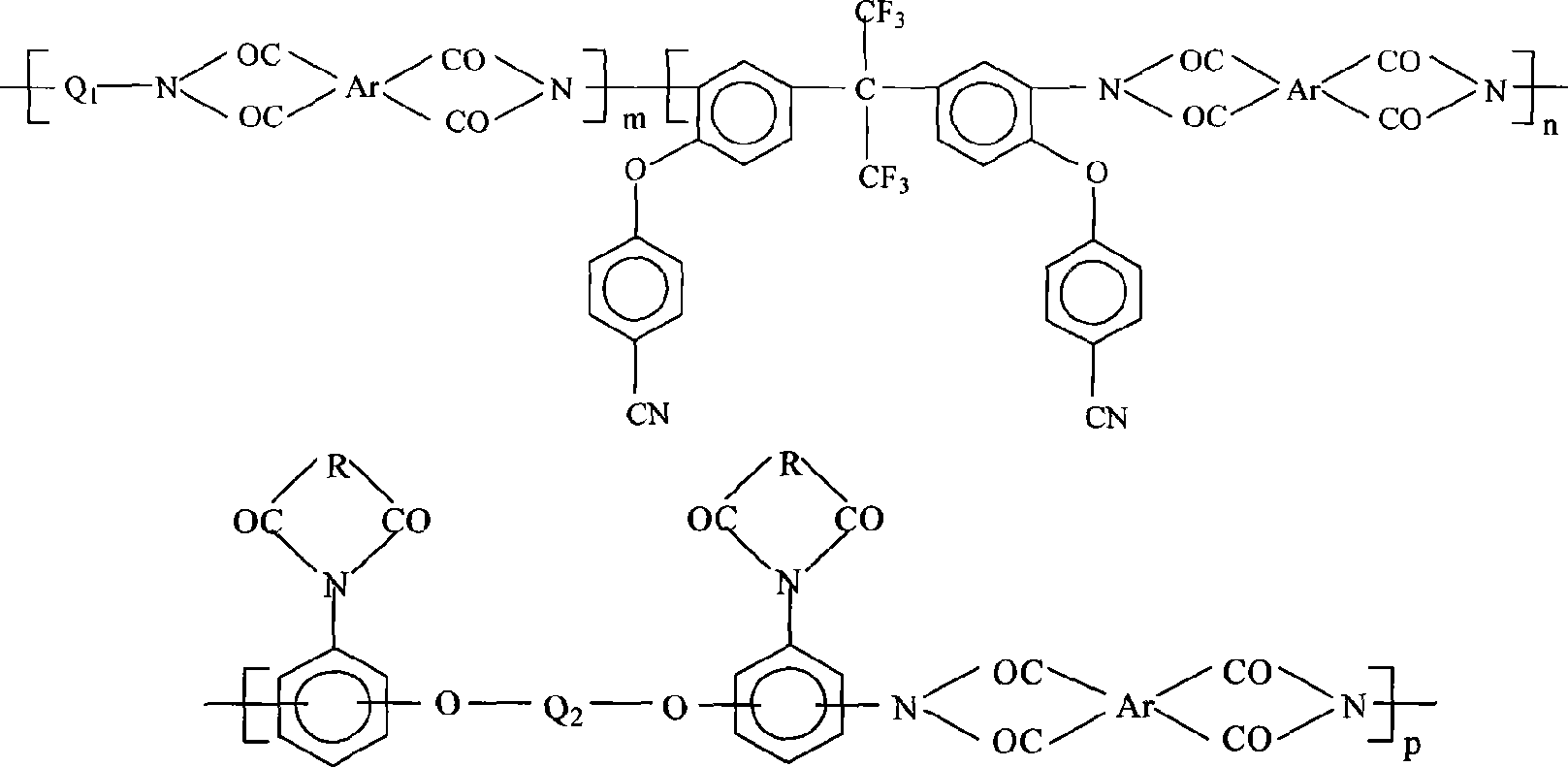

Method used

Image

Examples

Embodiment 1

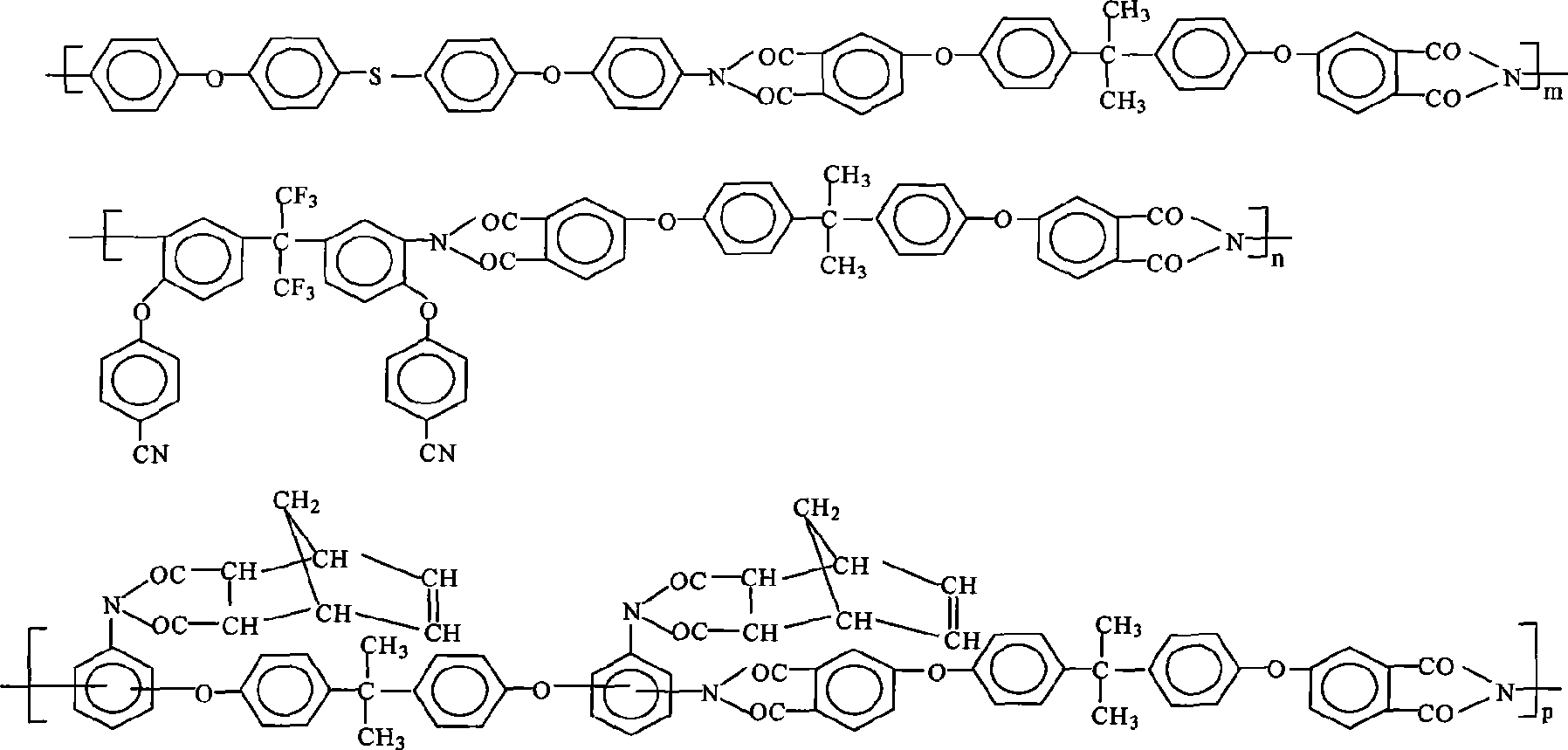

[0060] Put 54.8 grams (0.1 mol) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]hexafluoropropane and 5520 milliliters of N,N-dimethylacetamide into the reaction kettle , stirred, after complete dissolution, cooled to 0°C in an ice-water bath, added 19.6 grams (0.2 moles) of maleic anhydride, stirred within the temperature range of 0°C-20°C, after complete dissolution, maintained the reaction for 0.5 hours, added 568.5 grams (1.0 mole) of 2,2-bis[3-amino-4-(4-cyanophenoxy)phenyl]hexafluoropropane, 518.5 grams (1.0 mole) of 2,2-bis[4-(4 -Aminophenoxy)phenyl]hexafluoropropane, stirred, completely dissolved, cooled to 0°C in an ice-water bath, and added 676.2 grams (2.1 moles) of 3,3',4,4'-tetracarboxylic acid benzophenone Dianhydride, stirred within the temperature range of 0°C-20°C, after completely dissolving, after maintaining the reaction for 2 hours, add 552 ml of toluene and 18.8 g (0.11 moles) of p-toluenesulfonic acid, heat up, reflux and water separation reaction After 5 hours...

Embodiment 2

[0066] 44.1 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane, 1000 milliliters of N-methyl-2-pyrrolidone and 5979 milliliters of N,N-bis Put the methyl formamide into the reaction kettle, stir, and after it is completely dissolved, cool it in an ice-water bath to 0°C, add 32.8 grams (0.2 moles) of Nadic anhydride, stir it in the temperature range of 0°C-20°C, and dissolve it completely , maintained the reaction for 2 hours, added 56.8 grams (0.1 mole) of 2,2-bis[3-amino-4-(4-cyanophenoxy) phenyl] hexafluoropropane, 200.2 grams (0.5 mole) of 4 , 4'-bis(4-aminophenoxy)diphenyl sulfide, stirring, after completely dissolving, cooling to 0°C in an ice-water bath, adding 364.0 grams (0.7 moles) of 2,2-bis[4-(3, 4-dicarboxyphenoxy group) phenyl] propane dianhydride, stir in the temperature range of 0 ℃-20 ℃, after dissolving completely, after maintaining reaction for 4 hours, add 5979 milliliters of toluene, 1000 milliliters of dimethylbenzene and 119.7 grams ( 0.7 ...

Embodiment 3

[0072] 322.0 grams (1.0 mole) of 1,3-bis(2,4-diaminophenoxy)benzene and 5000 milliliters of N,N-dimethylacetamide were put into the reaction kettle, stirred, after completely dissolving, ice Cool in a water bath to 0°C, add 19.6 grams (0.2 moles) of maleic anhydride, stir in the temperature range of 0°C-20°C, after completely dissolving, maintain the reaction for 1.5 hours, add 56.8 grams (0.1 moles) of 2,2 -Bis[3-amino-4-(4-cyanophenoxy)phenyl]hexafluoropropane, 65.4 grams (0.1 moles) of 2,2-bis[4-(2-trifluoromethyl-4- Aminophenoxy)phenyl]hexafluoropropane, stirring, after completely dissolving, cooling to 0°C in an ice-water bath, adding 372.0 g (1.2 moles) of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride , stirred within the temperature range of 0°C-20°C, after completely dissolving, after maintaining the reaction for 3 hours, add 800 ml of toluene and 18.8 g (0.11 moles) of p-toluenesulfonic acid, heat up, reflux and divide water for 8 hours Finally, separate the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com