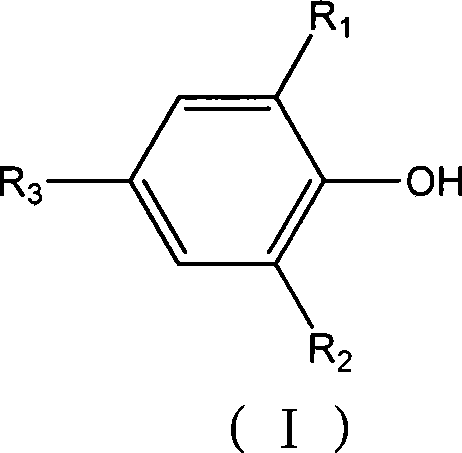

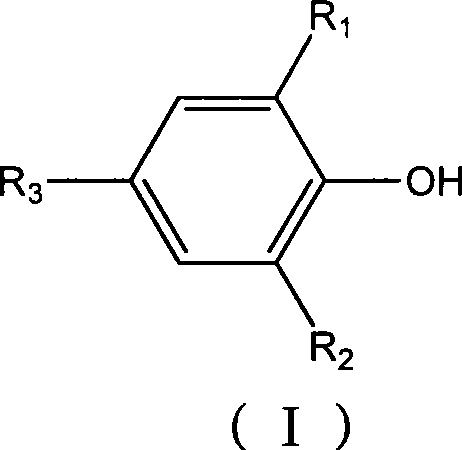

Magnetic supported catalyst and use thereof in polyphenylene oxide preparation

A supported catalyst and catalyst technology, which is applied in the direction of chemical recovery, can solve the unsolved problems of catalyst recovery and reuse, and achieve the effects of large specific surface area, high catalytic efficiency and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Preparation of Magnetic Loaded Metal Ion-PAMAM Dendrimer Catalyst

[0053] (1) Preparation of nano-ferric oxide

[0054] Prepare 250 mL of 0.5 mol / L sodium hydroxide solution and add it to a three-necked flask. Under the protection of nitrogen, the temperature was raised to 80°C. Configure 1mol / L FeCl 3 ·6H 2 O, 0.5mol / L FeCl 2 4H 2 O, 25 mL of 0.4 mol / L HCl solution was added to the above alkaline solution. Under mechanical stirring, react for 30 minutes. After the reaction, wash with distilled water and ethanol 5 times respectively. Vacuum drying at room temperature for 24 hours to prepare black nano iron ferric oxide powder.

[0055] (2) Surface amination of magnetic nanoparticles

[0056] 5g of the above-mentioned nano ferric oxide was redispersed in 200mL of toluene. Then 3 mL of 3-aminopropyltriethoxysilane was added. Heat to 105°C and react at this temperature for 20 hours with mechanical stirring. After the reaction, it was washed with meth...

Embodiment 2~4

[0063] The magnetically supported metal ion-PAMAM dendrimer catalyst was prepared according to the method of Example 1, except that the algebra of the copper compound and PAMAM (PAMAM Gn) was changed, as shown in Table 1.

[0064] Table 1

[0065] Example serial number Copper compound (mmol) Nitrogen content in PAMAM Gn (mmol) 2 Copper chloride (0.05) G2(0.1) 3 Copper nitrate (0.05) G3(0.1) 4 Copper sulfate (0.05) G4(0.1)

Embodiment 5~8

[0067] The magnetically supported metal ion-PAMAM dendritic compound catalyst was prepared according to the method of Example 1, except that the copper compound was replaced by a manganese compound, as shown in Table 2.

[0068] Table 2

[0069] Example serial number Manganese compound (mmol) Nitrogen content in PAMAM Gn (mmol) 5 Manganese chloride (0.05) G1(0.1) 6 Manganese bromide (0.05) G2(0.1) 7 Manganese nitrate (0.05) G3(0.1) 8 Manganese sulfate (0.05) G4(0.1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com