Mutant of cyclodextrin glucosyl transferase having highly beta-cyclodextrin yielding property and mutation method

A glucose-based and cyclodextrin technology, which is applied in the fields of genetic engineering and enzyme engineering, can solve the problems of inconvenient separation and purification of products and increase costs, and achieve the effect of improving specificity and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: This example illustrates the preparation of mutant enzymes K47R, K47H and K47T.

[0026] 1) Site-directed mutation

[0027] Utilize fast PCR technology, carry out site-directed mutation with the expression vector cgt / pET-20b(+) as template, and introduce the site-directed mutation primer of Arg47 codon as follows:

[0028] Forward primer: 5'-CGATCCAATTTG CGG CTCTATTTCGG-3' (the underline is the mutant base),

[0029] Reverse primer: 5'-CCGAAATAGAG CCG CAAATTGGATCG-3' (the underline is the mutated base), the site-directed mutagenesis primer for introducing the His47 codon is:

[0030] Forward primer: 5'-CGATCCAATTTG CAC CTCTATTTCGG-3' (the underline is the mutant base),

[0031] Reverse primer: 5'-CCGAAATAGAG GTG CAAATTGGATCG-3' (the underline is the mutated base), the site-directed mutagenesis primer for introducing the Thr47 codon is:

[0032] Forward primer: 5'-CGATCCAATTTG ACG CTCTATTTCGG-3' (the underline is the mutant base),

[0033] Reverse...

Embodiment 2

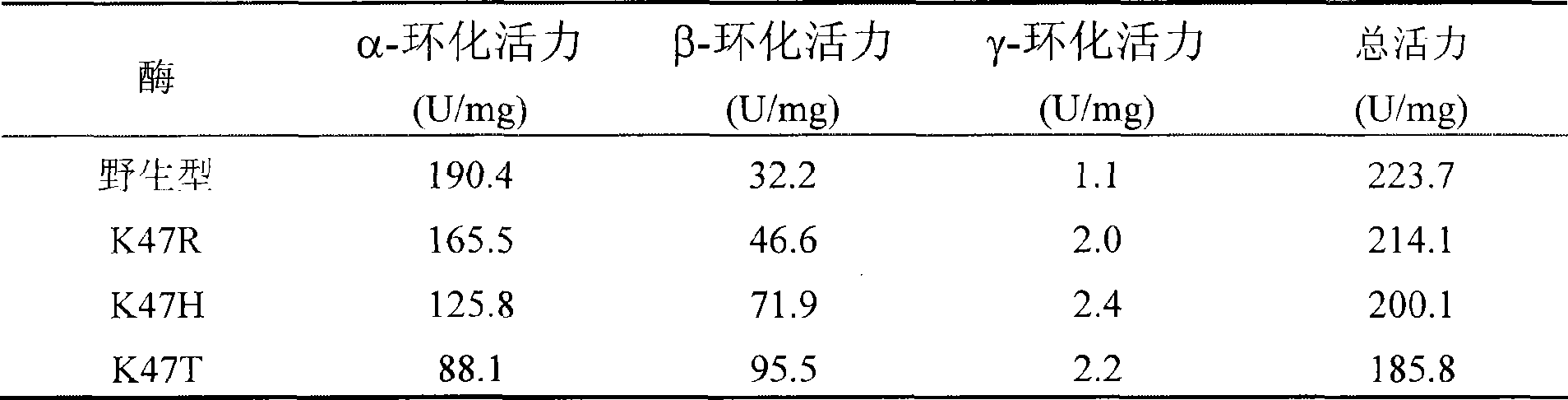

[0040] Example 2: This example illustrates an enzyme activity assay.

[0041] 1) Enzyme activity assay method

[0042] Method for measuring α-cyclization activity by methyl orange method: Take 0.1 mL of appropriately diluted enzyme solution, add 0.9 mL of 3% (w / v) soluble starch solution prepared in advance with 50 mM phosphate buffer (pH 6.5) After reacting at 40°C for 10min, add 1.0mL of 1.0N hydrochloric acid to stop the reaction, then add 1.0mL of 0.1mM methyl orange prepared with 50mM phosphate buffer, incubate at 16°C for 20min, and measure the absorbance at 505nm. One enzyme activity unit is defined as the amount of enzyme required to generate 1 μmol α-cyclodextrin per minute under the above conditions.

[0043] The method for the determination of β-cyclization activity by phenolphthalein method: take 0.1 mL of appropriately diluted enzyme solution and add it to a test tube containing 0.9 mL of 3% (w / v) soluble starch solution prepared in advance with 50 mM phosphate b...

Embodiment 3

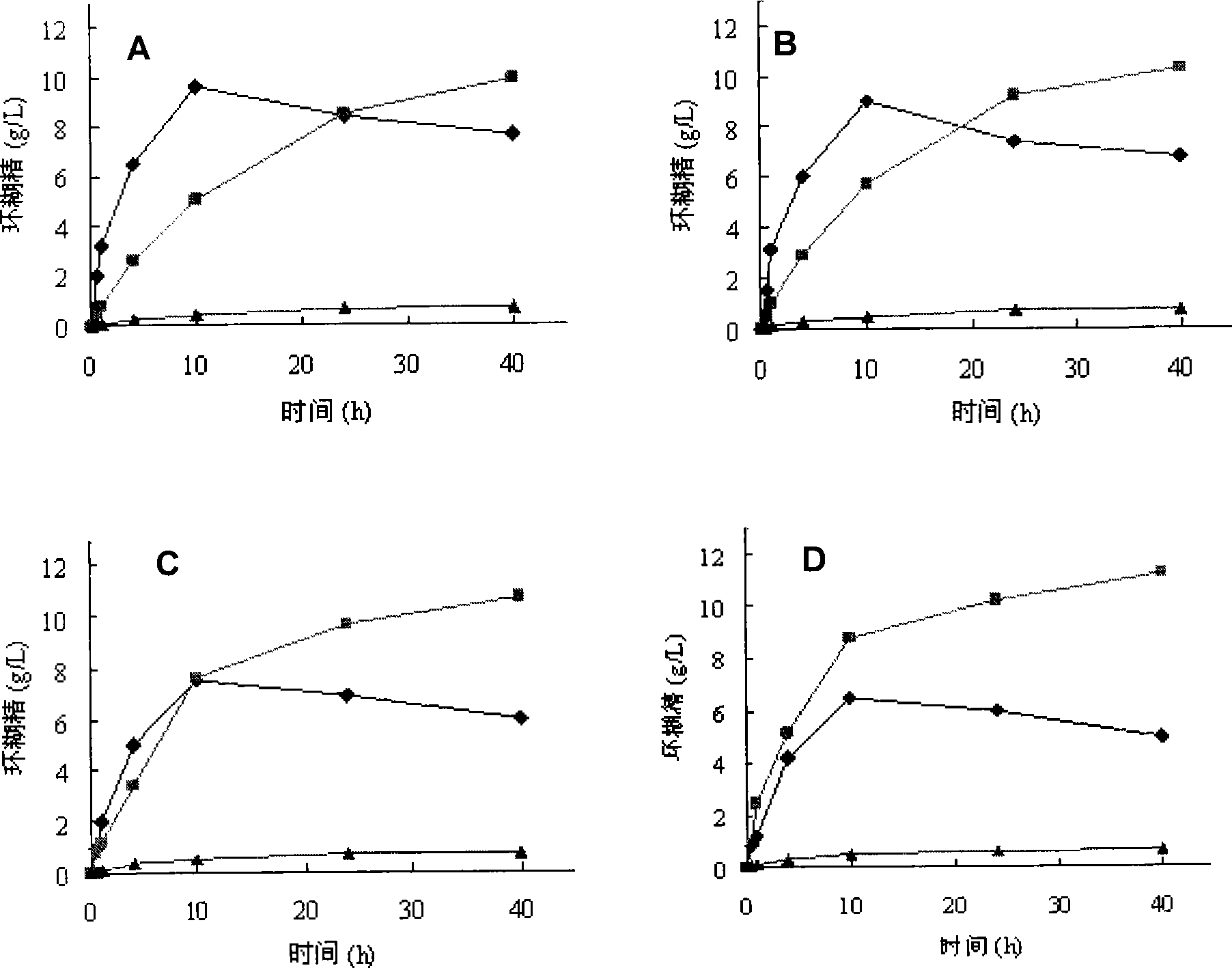

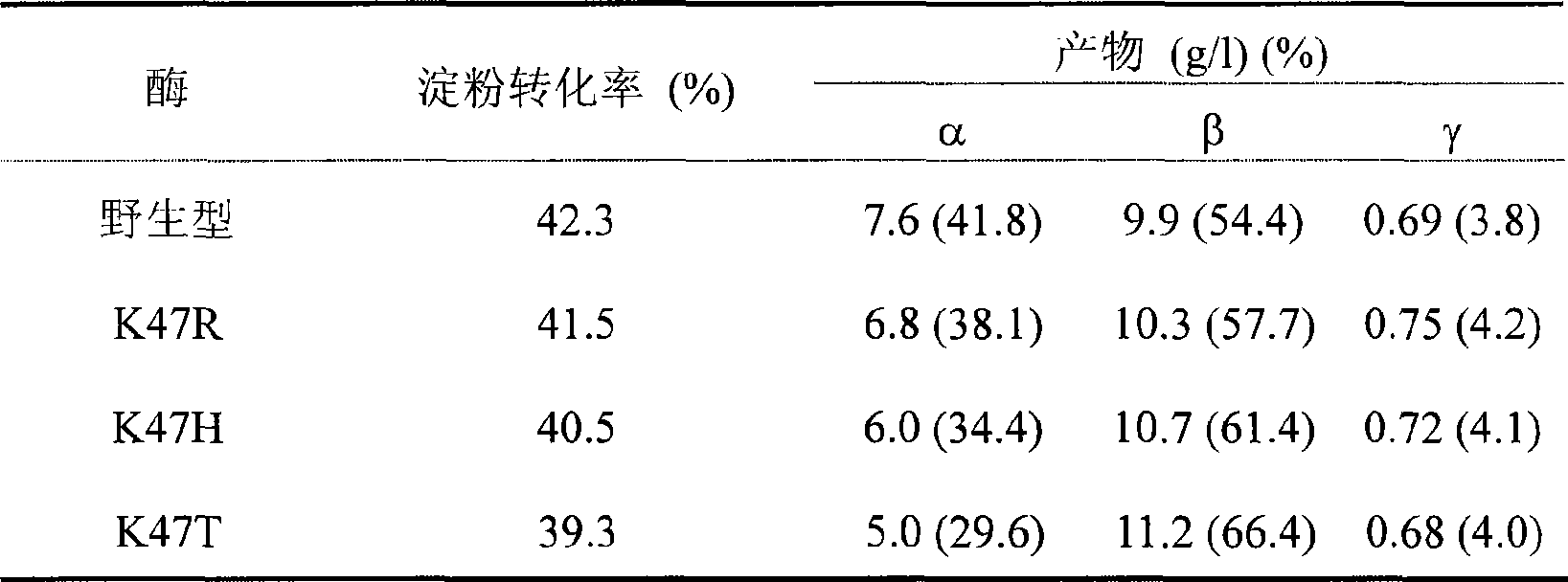

[0049] Example 3: This example illustrates the HPLC method for analyzing the amount of cyclodextrin produced.

[0050] Prepare 5% (wet basis, water content 8%, w / v) soluble starch solution as substrate, dissolve 5g starch in 90mL sodium phosphate buffer (pH 6.0), dilute to 100mL, boil in boiling water for 30min. Add a certain amount of wild CGTase, mutant enzyme K47R, K47H, or K47T to make the enzyme activity in the reaction system 0.2U / mL, place it at 40°C for 40h, take 600μL of samples at intervals, centrifuge at 12000rpm for 10min, and take 500μL of supernatant , add 5 μL of glucoamylase (70 U / mL), saccharify at 30°C for 1 hour, inactivate by boiling for 10 minutes, centrifuge at 12,000 rpm for 30 minutes, and take 20 μL of the supernatant for HPLC analysis after filtering through a 0.45 μm ultrafiltration membrane.

[0051] The concentration of α-, β-, and γ-cyclodextrin in the reaction solution is measured by HPLC, and the chromatographic conditions for product analysis b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com