Metal phthalocyanine/carbon nano tube composite catalyst and its preparation method and lithium/thinly chloride battery using the catalyst

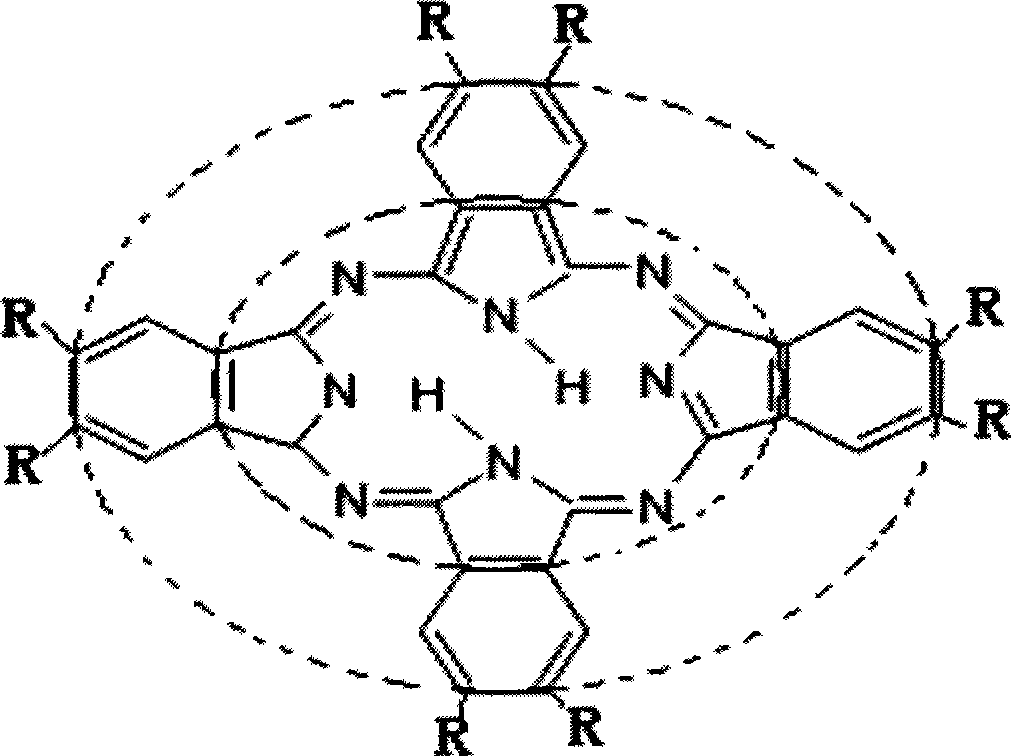

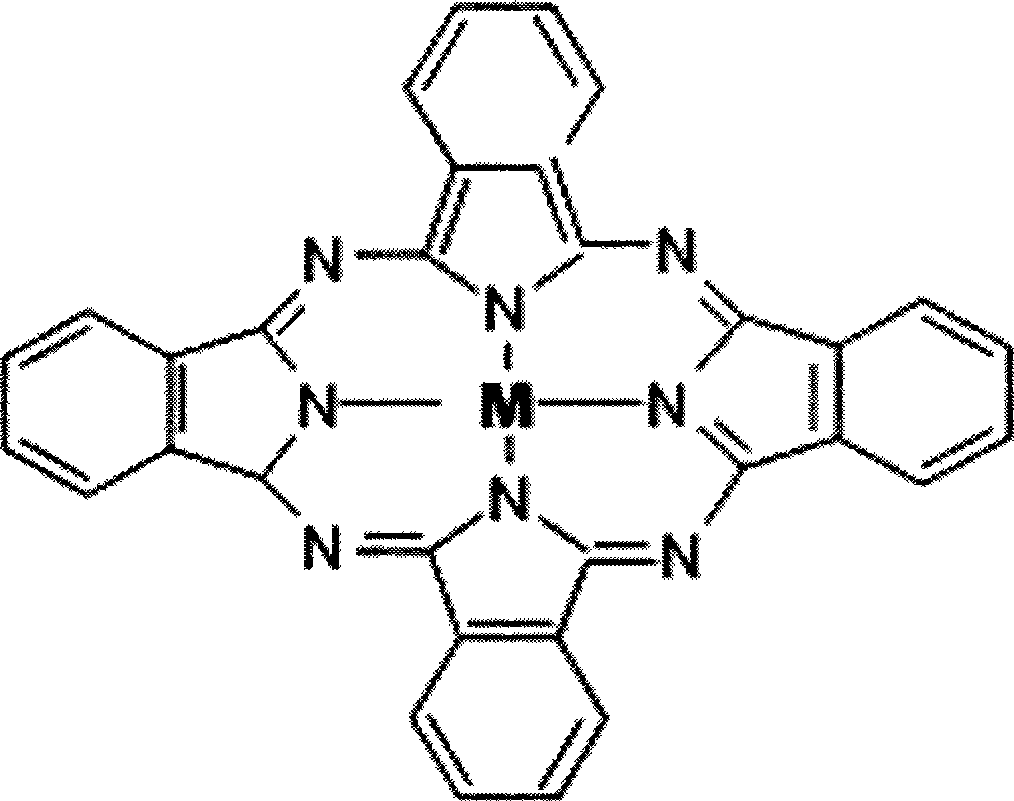

A carbon nanotube composite, metal phthalocyanine technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems such as chemical change, unfavorable battery discharge, etc., to achieve significant practical value and economic benefits, improve the discharge voltage, and the effect of large migration space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 1 g of purified multi-walled carbon nanotubes and add them to 200 ml of thionyl chloride, reflux at 70° C. for 24 hours under the protection of argon, and then distill under reduced pressure to remove the remaining thionyl chlorides to obtain acid-chlorinated carbon nanotubes; Take 0.5 g of acid-chlorinated carbon nanotubes, add 1.5 g of cobalt phthalocyanine, 100 g of dimethylformamide and 0.12 g of pyrimidine under the protection of argon, and react at 110 ° C for 10 days; filter the above solution with a microfiltration membrane, And rinse with dimethylformamide to remove excess cobalt phthalocyanine to obtain a black fluffy powder, which is cobalt phthalocyanine / carbon nanotube composite catalyst.

Embodiment 2

[0050] Weigh 1 g of purified multi-walled carbon nanotubes and add them to 200 ml of thionyl chloride, reflux at 70° C. for 24 hours under the protection of argon, and then distill under reduced pressure to remove the remaining thionyl chlorides to obtain acid-chlorinated carbon nanotubes; Take 0.5 g of acid-chlorinated carbon nanotubes, add 1.5 g of iron phthalocyanine, 100 g of dimethylformamide and 0.12 g of pyrimidine under the protection of argon, and react at 110 ° C for 10 days; filter the above solution with a microfiltration membrane, And rinse with dimethylformamide to remove excess iron phthalocyanine to obtain a black fluffy powder, which is the iron phthalocyanine / carbon nanotube composite catalyst.

Embodiment 3

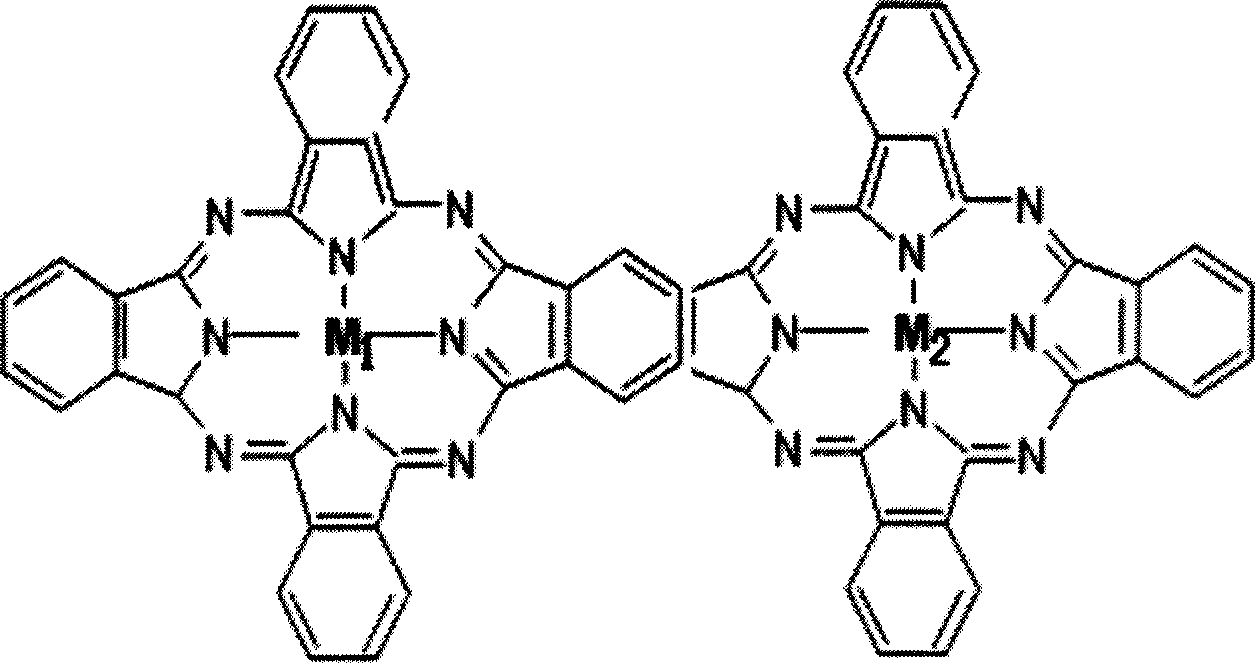

[0052] Weigh 1 g of purified multi-walled carbon nanotubes and add them to 200 ml of thionyl chloride, reflux at 75° C. for 48 hours under the protection of argon, and then distill under reduced pressure to remove the remaining thionyl chlorides to obtain acid-chlorinated carbon nanotubes; Take 0.5 g of acid-chlorinated carbon nanotubes, add 1 g of dinuclear nickel phthalocyanine, 75 g of dimethylformamide and 0.08 g of pyrimidine under the protection of argon, and react at 105 ° C for 9 days; filter the above solution with a microfiltration membrane, And rinse with dimethylformamide to remove excess binuclear nickel phthalocyanine to obtain a black fluffy powder, which is the binuclear nickel phthalocyanine / carbon nanotube composite catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com