Method for preparing microbe diesel oil by ionic liquid catalysis

An ionic liquid, catalytic preparation technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problems of non-compliance and high cost of biodiesel, and achieve stable performance, no acid loss, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

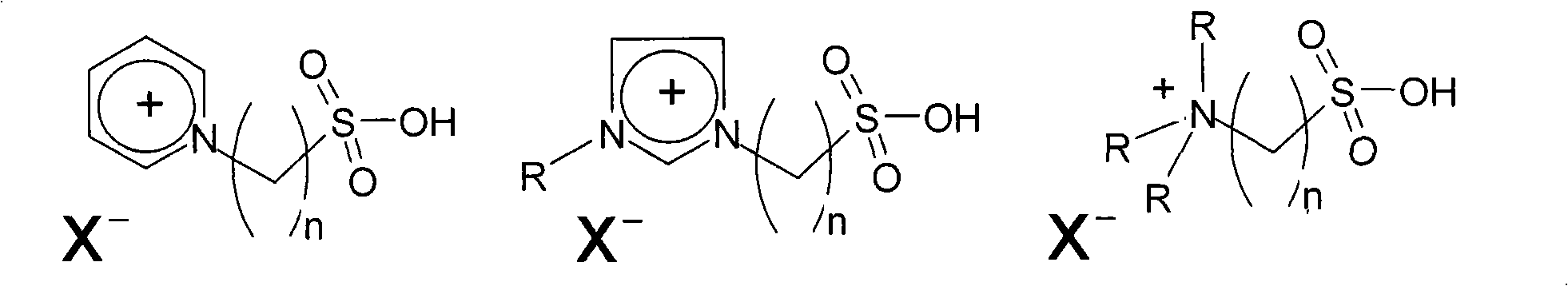

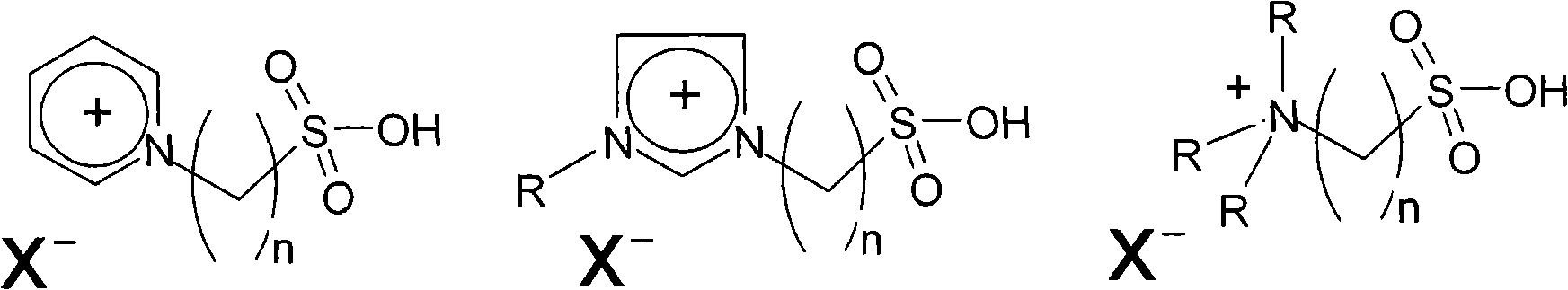

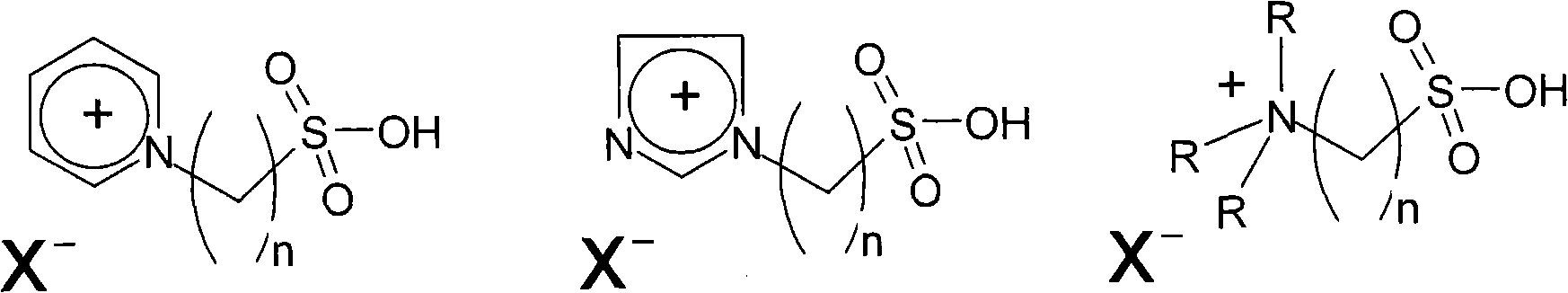

Image

Examples

preparation example Construction

[0032] 1) Preparation process of acid-functionalized ionic liquid: 24.4 parts by mass of 1,3-propane sultone were dissolved in 200 parts by mass of ethyl acetate, heated to 50°C, and 16.4 parts by mass of N-methyl After the addition of imidazole is completed, after 3 hours of heat preservation reaction, filter, wash the filter cake with ethyl acetate, and dry at 100°C for 2 hours to obtain white solid 1-(3-sulfonic acid)propyl-3-methanol Imidazolium salt; get 20.4 parts of quality 1-(3-sulfonic acid group) propyl group-3-methylimidazolium salt, dissolve in 50 parts of quality deionized water, add dropwise the concentrated sulfuric acid (98%) of 9.8 parts of quality , after the dropwise addition, the temperature was raised to 90° C. and kept for 3 hours for reaction. After the reaction was completed, dehydration was performed under reduced pressure to obtain a light yellow viscous liquid 1-(3-sulfonic acid) propyl-3-methylimidazolium hydrogen sulfate.

[0033] 2) Preparation of...

Embodiment 1

[0035] Example 1: Put 7 grams of acid-functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazole hydrogen sulfate, 28.2 grams of free fatty acid, and 13.8 grams of ethanol into a reaction flask, stir, Heating, the esterification reaction temperature is 60°C to 120°C. After reacting for 9 hours, the reaction liquid was allowed to stand and separated into layers, the upper layer of the reaction liquid was poured out, and purified by distillation. The conversion rate of free fatty acid was 96.3%.

Embodiment 2

[0036] Example 2: Put 4 grams of acid-functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazole hydrogen sulfate, 28.2 grams of free fatty acid, and 9.6 grams of methanol into a reaction flask, stir, Heating, the esterification reaction temperature is 60°C to 80°C. After reacting for 6 hours, the reaction solution was allowed to stand and separated into layers, the upper layer of the reaction solution was poured out, and purified by distillation. The conversion rate of free fatty acid was 92.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com